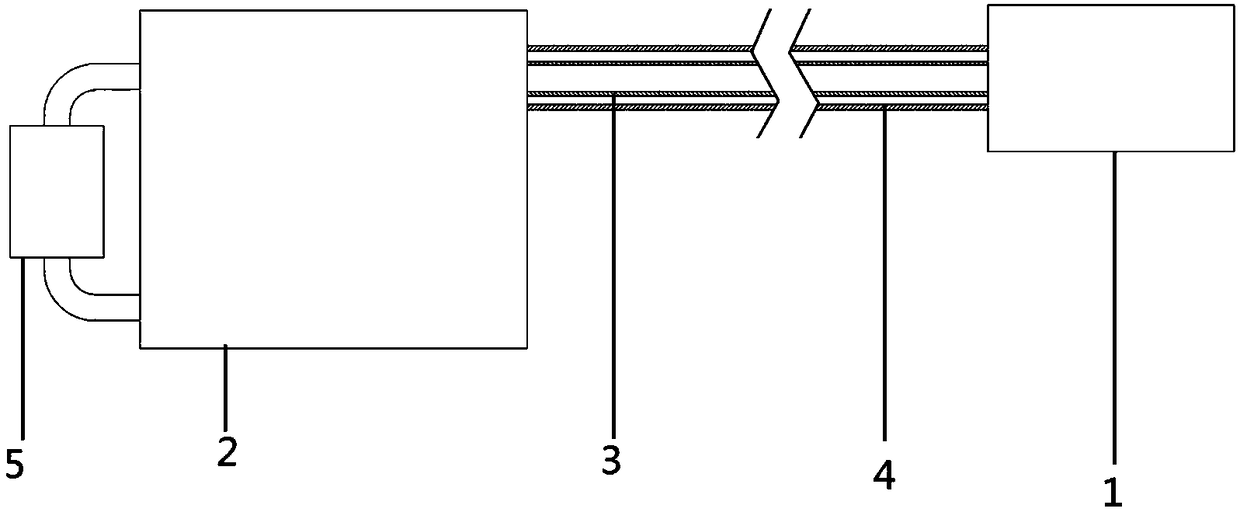

Compact antigravity loop heat pipe

A loop heat pipe, anti-gravity technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large system space, unreliable work, complicated structure, etc., to save system space, reduce system space, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

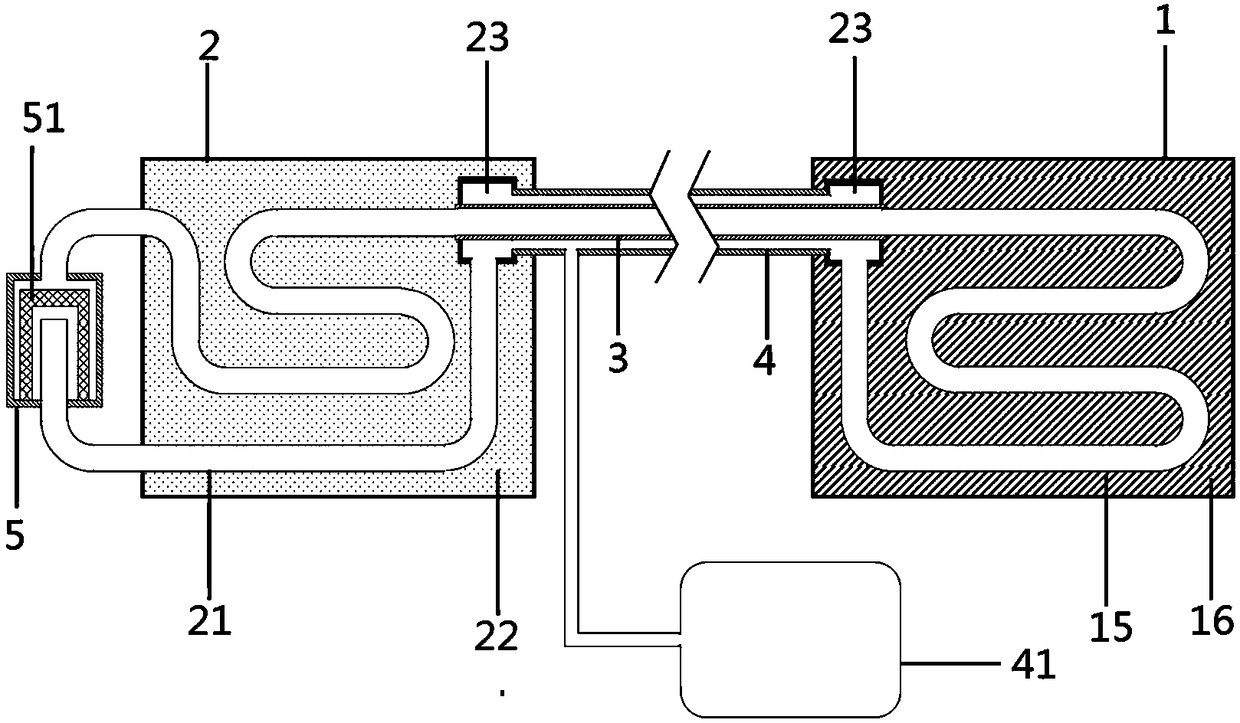

[0087] This embodiment has the same basic structure as the above-mentioned embodiments. For the sake of brevity, in the description process of this embodiment, the same technical features as the above-mentioned embodiments will not be described in detail to illustrate that this embodiment is different from the above-mentioned embodiments. Mainly:

[0088] refer to figure 2 , This embodiment provides a compact anti-gravity loop heat pipe On the basis of the above embodiments, the evaporator 1 is a cylindrical structure. A liquid-absorbing core 11 is arranged in the evaporator 1 , and the liquid-absorbing core 11 is cup-shaped with an open side close to the liquid pipeline and a closed side away from the liquid pipeline. That is, the liquid-absorbing core 11 is a cylindrical shape with an opening at one end, and the opening end faces the liquid pipeline.

[0089] A baffle 14 is provided at the end of the opening side of the liquid-absorbing core 11 to isolate the inner space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com