Carbon dioxide low-temperature Rankine cycle power generation system

A carbon dioxide and Rankine cycle technology, applied in the direction of machines/engines, steam engines, mechanical equipment, etc., can solve the problems of low exhaust gas temperature, low efficiency, and difficulty in effectively reducing carbon dioxide emissions, so as to improve the utilization rate and energy. Utilization rate, effect of reducing heat source cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

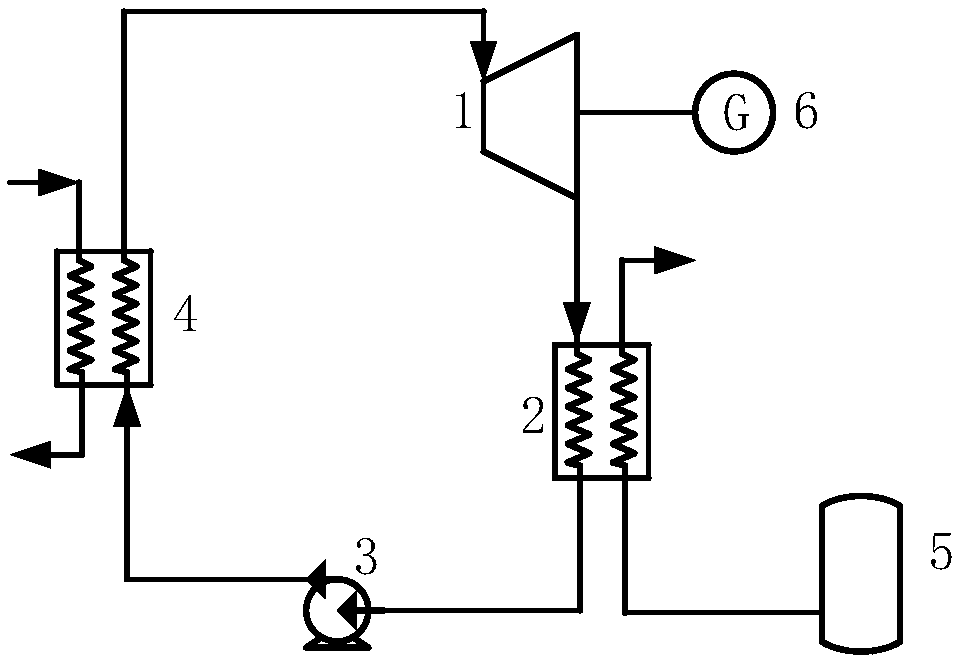

[0032] Such as figure 1 As shown, a carbon dioxide low-temperature Rankine cycle power generation system includes a turbine 1 , a condenser 2 , a working medium pump 3 , an air heater 4 , an LNG liquid storage tank 5 and a generator 6 .

[0033] Among them, the cold side outlet of the air heater 4 is connected to the gas inlet of the turbine 1, the turbine 1 is connected to the generator 6, the gas outlet of the turbine 1 is connected to the hot side inlet of the condenser 2, and the hot side outlet of the condenser 2 It is connected to the inlet of the working medium pump 3, and the outlet of the working medium pump 3 is connected to the cold side inlet of the air heater 4.

[0034] Ambient air enters from the inlet of the hot side of the air heater 4 to exchange heat with the liquid carbon dioxide on the cold side, and then discharges to the atmosphere from the outlet of the hot side; the condenser 2 uses low-temperature LNG to cool the carbon dioxide, and the outlet of the ...

Embodiment 2

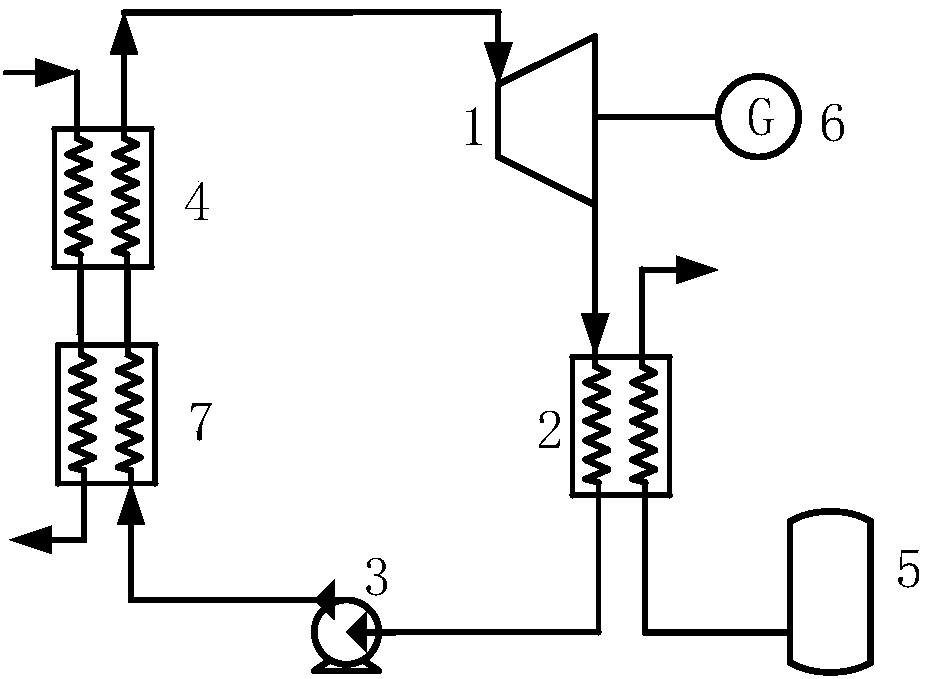

[0038] The carbon dioxide low-temperature Rankine cycle power generation system provided in this embodiment adds a preheater 7 on the basis of the power generation system in Embodiment 1, and the preheater 7 is connected in series with the air heater 4 .

[0039] Such as figure 2 As shown, the cold side inlet of the preheater 7 is connected to the outlet of the working medium pump 3, and the cold side outlet of the preheater is connected to the cold side inlet of the air heater 4;

[0040] The hot side inlet of the preheater 7 is connected with the hot side outlet of the air heater 4, and the hot side outlet of the preheater 7 leads to the atmosphere.

[0041]After the liquid carbon dioxide is boosted by the working medium pump 3, it is discharged from the outlet of the working medium pump 3 and enters the preheater from the cold side inlet of the preheater 7 through the pipeline, and then enters the air from the cold side outlet of the preheater 7 for heating In the cold en...

Embodiment 3

[0045] The carbon dioxide low-temperature Rankine cycle power generation system provided in this embodiment has the same structure as that of the power generation system in Embodiment 1, except that the working fluid pump 3 is connected to the turbine 1, and one or more transmissions are added. The specific connection method as follows:

[0046] Such as image 3 As shown, the shaft of the working medium pump 3 is connected with the transmission, and the transmission is connected with the output shaft of the turbine.

[0047] Carbon dioxide enters the turbine for thermal power conversion. Turbine 1 rotates and drives the transmission connected to it to rotate. The speed of turbine 1 is adjusted to the speed of working medium pump 3 through the transmission to drive working medium pump 3 to rotate. The kinetic energy generated by the turbine 1 drives the working medium pump to work, which saves the electric energy required by the working medium pump and improves the utilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com