Composite coal water slurry additive and preparation process thereof

A preparation process, technology of coal water slurry, applied in fuel additives, petroleum industry, liquid carbon-containing fuel, etc., can solve problems such as increased concentration of coal water slurry, poor slurry stability, easy to produce hard deposits, etc., to save heat energy , Improve product performance, shorten the effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

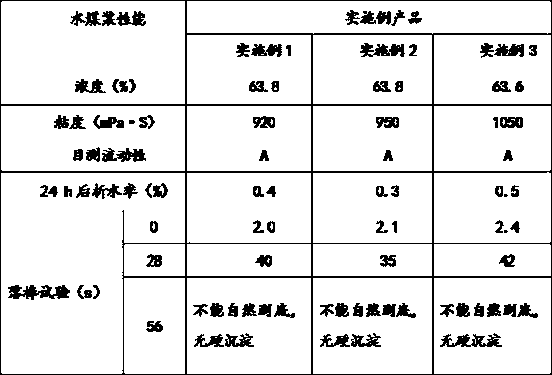

Examples

preparation example Construction

[0021] The preparation process of the present invention is as follows:

[0022] (1) Preparation of acid regulator: first place naphthalene and its homologues in a sulfonation reaction kettle, heat up to 135~145 °C, add concentrated sulfuric acid, and perform sulfonation reaction at 155~160 °C for 2~3 h; Transfer to the hydrolysis and condensation reaction kettle, lower the temperature to 120~125 °C, and then pass in water at 70~90 °C for 0.5~1.0 h of hydrolysis reaction, slowly add formaldehyde, and condense at 100~105 °C for 4~5 hours, Add water to dilute to a solid content of 30.0% to obtain an acidic regulator.

[0023] (2) Preparation of composite coal water slurry additive: first put the pulping black liquor into a reaction kettle with good thermal insulation performance, add 150°C saturated steam to raise the temperature of the reaction system to 50~60°C, and then add step (1) Prepared acid regulator, adjust the pH to 10.5~11.5, then add hydrogen peroxide, and oxidize f...

Embodiment 1

[0032] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0033] Methyl naphthalene: 77 kg

[0034] Concentrated sulfuric acid (98%): 66 kg

[0035] Formaldehyde (37%): 56 kg

[0036] Masson pine caustic soda pulping black liquor (solid content 50%): 310 kg

[0037] Saturated water vapor at 150°C: 77kg

[0038] Hydrogen peroxide (30%): 6 kg

[0040] Water: 385 kg

[0041] 2. Preparation process steps and parameters:

[0042] (1) Preparation of acid regulator: first place 77 kg of methylnaphthalene in a sulfonation reactor, heat up to 135 °C, add 66 kg of concentrated sulfuric acid with a content of 98%, and sulfonate at 155 °C for 3.0 h; Transfer the reaction materials to the hydrolysis and condensation tank, lower the temperature to 120 °C, and then pass 15 kg of hot water at a temperature of 90 °C to carry out the hydrolysis reaction for 0.5 h, then slowly add 44 kg of formaldehyde solution with a s...

Embodiment 2

[0045] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0046] Naphthalene and its homologues (a mixture of naphthalene and methylnaphthalene, the mass ratio is 1:1): 76 kg

[0047] Concentrated sulfuric acid (98%): 70 kg

[0048] Formaldehyde (37%): 54 kg

[0049] Soda pulping black liquor (mixture of poplar and eucalyptus, mass ratio 1:3, solid content: 45%): 322 kg

[0050] Saturated water vapor at 150°C: 80kg

[0051] Hydrogen peroxide (30%): 4 kg

[0052] Sodium metabisulfite: 22 kg

[0053] Water: 372 kg

[0054] 2. Preparation process steps and parameters:

[0055] (1) Preparation of acid regulator: first place 76 kg of industrial naphthalene and methylnaphthalene in a sulfonation reactor, heat up to 140 °C, add 70 kg of concentrated sulfuric acid with a content of 98%, and sulfonate it at 160 °C 2.5 h; transfer the reaction materials to the hydrolysis and condensation reaction kettle, cool down to 125 °C, and then pass 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com