Elastic shape memory material with shear thickening performance, and preparation method and applications thereof

A memory material and elastic technology, applied in the field of intelligent material manufacturing and application, can solve the problems of easy deformation, increased wearing comfort, inability to fix the shape and fit, etc., to achieve excellent impact resistance and increase the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

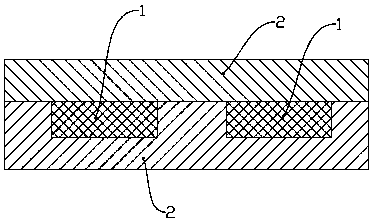

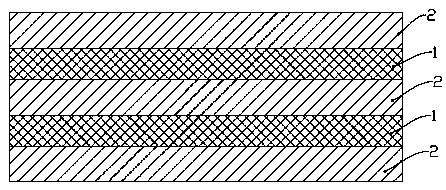

Image

Examples

Embodiment 1-1

[0025] 1. Two-component heat-curing silicone (resin and curing agent) and thermoplastic polyurethane (TPU) are used for the elastic shape memory polymer. The weight part of the silicone is 50, and the weight part of the thermoplastic polyurethane is 30; the shear thickening material is D3O material , parts by weight are 20.

[0026] 2. Add thermoplastic polyurethane and shear thickening material into the silicone resin, heat until the mixture melts, and stir evenly.

[0027] 3. Add the curing agent and continue to stir evenly.

[0028] 4. Complete the curing according to the curing conditions provided by the silica gel manufacturer, and the obtained mixture of silica gel, thermoplastic polyurethane and shear thickening material is the target material;

[0029] 5. The elastic modulus of this mixed material is 0.01MPa and the shear modulus is 0.01 MPa under static or slow external load; under the action of instantaneous impact load, the elastic modulus is 0.1 GPa and the shear ...

Embodiment 1-2

[0031] 1. The elastic shape memory polymer is made of two-component heat-curing silica gel (resin and curing agent) and polycaprolactone (PCL), wherein the weight percentage of silica gel is 45, and the weight percentage of polycaprolactone is 25; shear thickening The material is P4U material, and the parts by weight are 30.

[0032] 2. Add the polycaprolactone and the shear thickening material into the silicone resin, and heat to a temperature higher than the melting point of the polycaprolactone and the shear thickening material, and stir evenly.

[0033] 3. After cooling, add curing agent and stir evenly with a mixer.

[0034] 4. According to the curing conditions provided by the manufacturer, cure the silica gel to obtain the target material;

[0035] 5. The elastic modulus of this mixed material is 0.05 MPa and the shear modulus is 0.04 MPa under static or slow external load; under the action of instantaneous impact load, the elastic modulus is 0.5 GPa and the shear modu...

Embodiment 1-3

[0037] 1. The elastic shape memory polymer is thermoplastic polyurethane (TPU), its melting point is 120°C, and the number of parts by weight is 60; the shear thickening material is D3O mixed with 20% by weight of polyethylene glycol powder, the number of parts by weight is 40;

[0038] 2. Heat the thermoplastic polyurethane above the melting point temperature, and add shear thickening material;

[0039] 3. Stir the mixture of thermoplastic polyurethane and shear thickening material evenly with a mixer above the melting point temperature;

[0040] 4. Cool until the material is hardened to obtain the target material.

[0041] 5. The elastic modulus of this mixed material is 0.1 MPa under static or slow external load, and the shear modulus is 0.08 MPa; under the action of instantaneous impact load, the elastic modulus is 1 GPa, and the shear modulus is 1.5 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Shear modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com