A high-performance lightweight aggregate for structural engineering

A structural engineering, high-performance technology, applied in the field of building materials, can solve the problems of few types, low strength, high water absorption, and achieve the effect of improving various properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

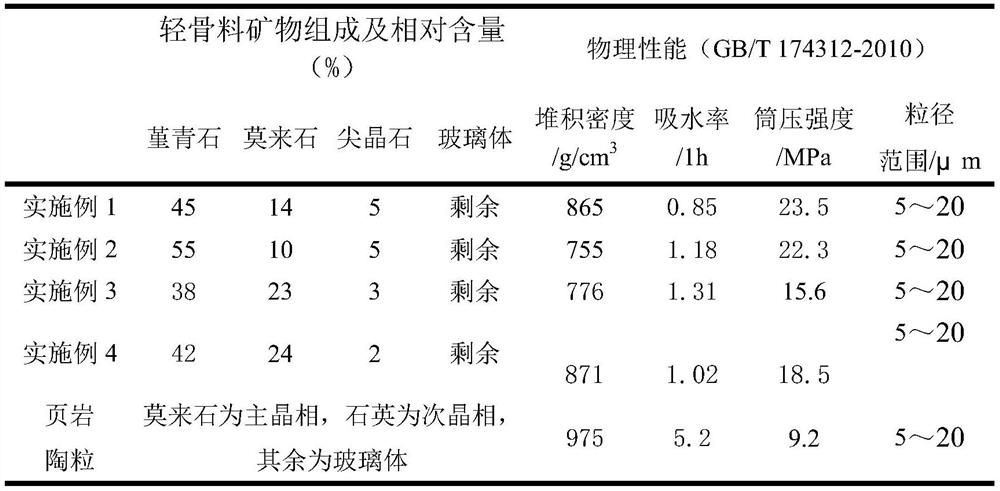

Examples

example 1

[0025] The main process of producing high-performance light bones on the binocular rotary kiln ceramics production line is:

[0026] 1) The mixture is mixed with a mandatory stirring mixer, and the raw powder passes through the belt conveyor into the ball disk, and the light bone material ball, agonized, and after drying after 8 ~ 12mm;

[0027] 2) Light bone material balls from the kiln tail feeding into the rotary kiln system, preheating the kiln (rear section of the double barrel rotary kiln) Rotary 1.2R / min, calcined kiln (front section of the double barrel rotary kiln) turn 1.8R / min, life The residence time in the kiln in the kiln is about 30 to 60 min, and the temperature of the kiln head is controlled at 1250 to 1380 ° C;

[0028] 3) After the roasting clinker is removed by the kiln head, the discharge temperature is 950 to 1100 ° C, forced air cooling to 100 ° C, and is sent to the yard by the conveyor;

[0029] Among them, the raw material and ingredients of the raw p...

example 2

[0031] The specific implementation process of the process process is in Example 1, in which the raw material and ingredients of the raw powder and the ingredients are 45 copies, 1 kaolin, 5 partsilish ash, 29 parts of the dolomite; every 100 Base) Add: 1 part of calcium carbonate, 5 copies of pulverized coal, 2 parts TiO2.

example 3

[0033] The specific implementation process of the process process is in Example 1, in which the raw material and ingredients of the raw powder and the ingredients are: 1,4 of aluminum soil, 54 high-carbon chrome-free metal; Base) Add: 1 coal, 5 pieces of iron powder, 5 parts of TiO2, 2 parts ZrO2, 0.5 parts boron oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com