Electric-conduction composite material, negative electrode material prepared from electric-conduction composite material, and secondary battery

A conductive composite material and secondary battery technology, which is applied in the direction of secondary batteries, batteries, battery electrodes, etc., can solve the problems of reducing overall structural stability, insufficient commercial value of secondary batteries, and structural rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

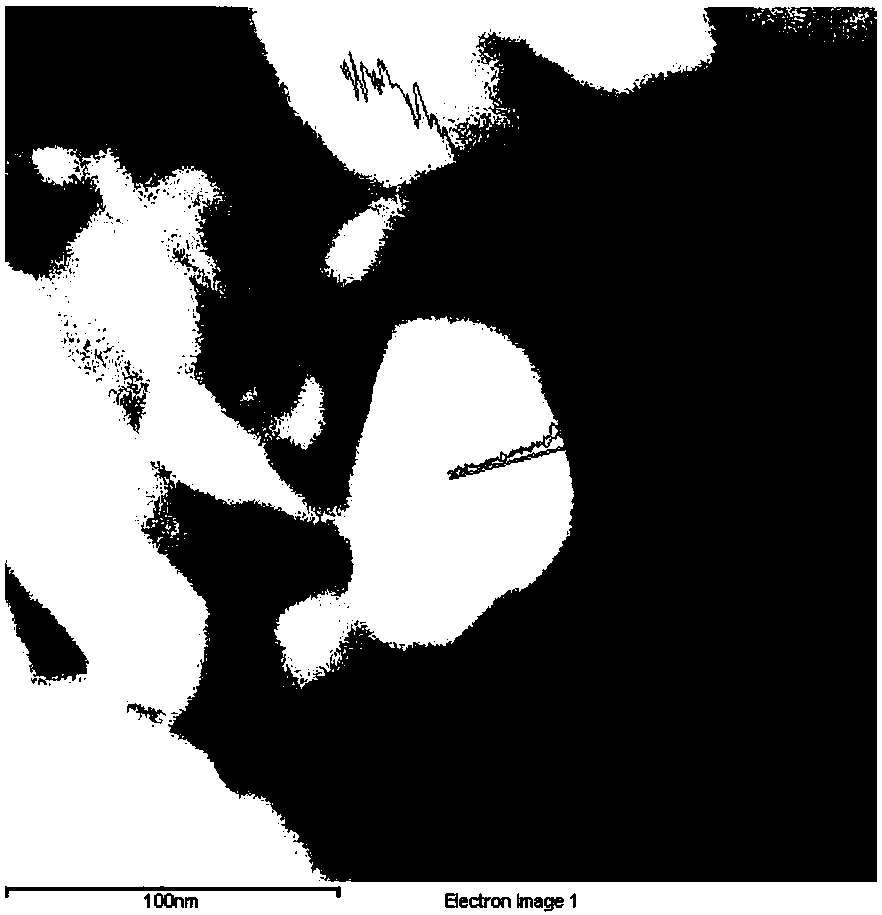

[0055] Example 1 - Preparation of Conductive Composite Material General Formula-Core Part / Inner Cladding Layer / Outer Cladding Layer (Si / SiOx / C:N, 0.3≤x≤1.5)

[0056] Step 1: Select silicon powder (particle size distribution of 1nm ~ 10μm) as the core part, and place it in a cavity that can be vacuumed, and the vacuum of the cavity is evacuated to 5x10 -4 Torr. The above-mentioned cavity can be any reactor with heating, and can be selected from reactors capable of continuous or batch processing according to the special purpose, such as: fluidized bed reactor, rotary furnace, vertical moving bed reactor, tunnel furnace , batch furnace and rotary kiln. The above-mentioned silicon powder body can be spherical or irregular.

[0057] Step 2: Then the cavity is fed with oxygen and heated to 800°C to form an inner cladding layer composed of silicon oxide on the surface of the core part composed of silicon powder. The general formula of silicon oxide is SiOx(0.3 ≤x≤1.5), wherein whe...

Embodiment 2

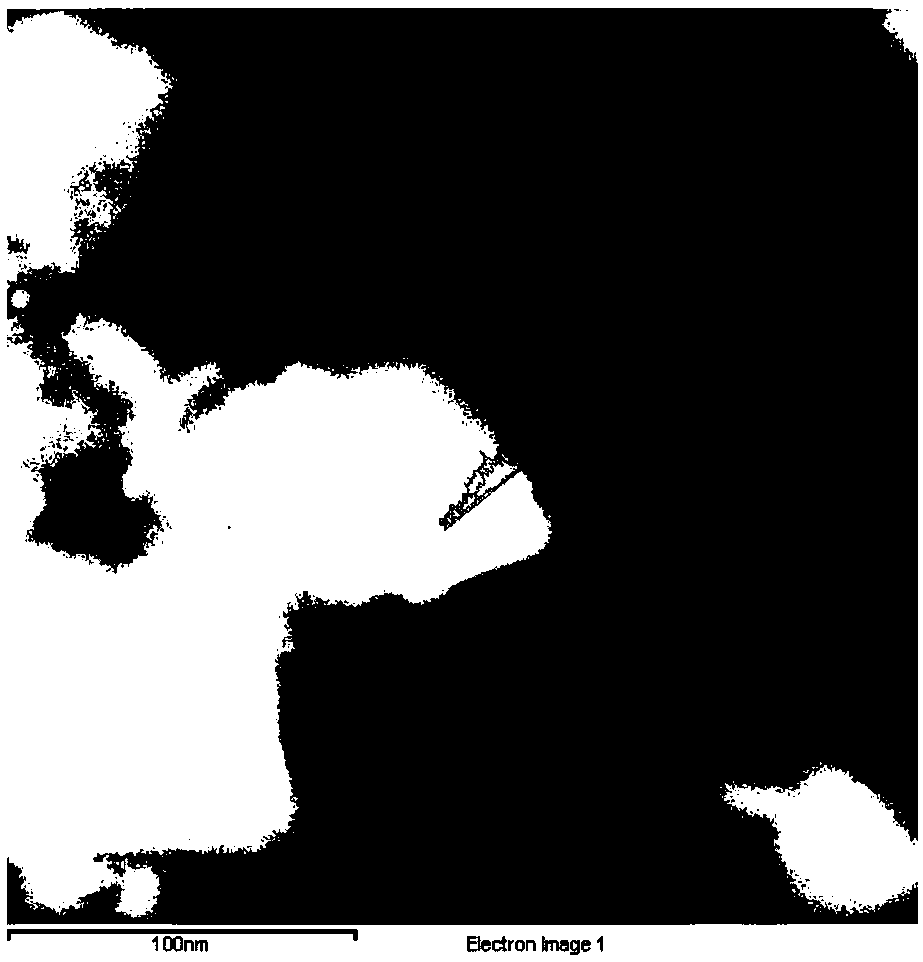

[0060] Embodiment 2 - Preparation of conductive composite material general formula-core part / inner cladding layer / outer cladding layer (Si / SiOx / C:F, 0.3≤x≤1.5);

[0061] Step 1: Select silicon powder (with a particle size distribution of 1nm to 5μm) as the core, and place it in a cavity that can be vacuumed, and the vacuum of the cavity is evacuated to 5x10 -4 Torr. The above-mentioned chamber can be any reactor with heating, which has been described in Example 1 and will not be repeated here. The above-mentioned silicon powder body can be spherical or irregular.

[0062] Step 2: Then the cavity is fed with oxygen and heated to 800°C to form an inner cladding layer composed of silicon oxide on the surface of the core part composed of silicon powder. The general formula of silicon oxide is SiOx(0.3 ≤x≤1.5), wherein when the oxygen flow rate is changed from 10 standard cubic centimeters per minute (sccm) to 50 standard cubic centimeters per minute (sccm), X of the general form...

Embodiment 3

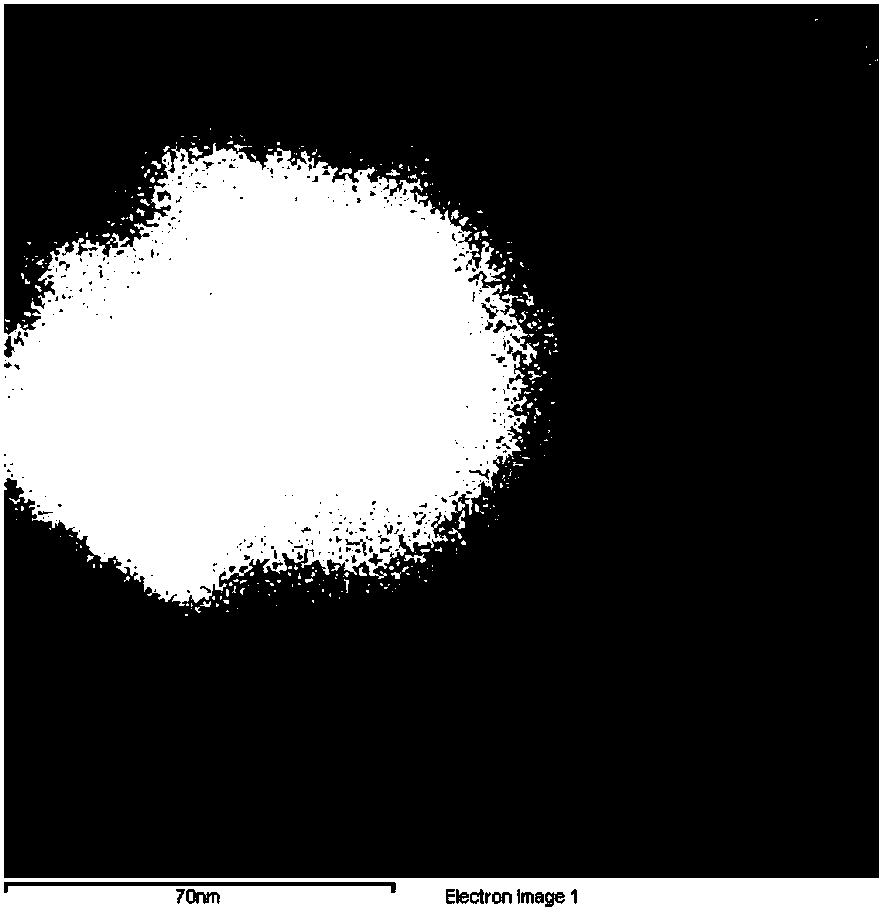

[0065] Example 3 - Preparation of Conductive Composite Material General Formula-Core Part / Inner Cladding Layer / Outer Cladding Layer (Si / SiNx / C:N, 0.1≤x≤0.8)

[0066] Step 1: Select silicon powder (with a particle size distribution of 1nm to 5μm) as the core, and place it in a cavity that can be vacuumed, and the vacuum of the cavity is evacuated to 5x10 -4 Torr. The above-mentioned chamber can be any reactor with heating, which has been described in Example 1 and will not be repeated here. The above-mentioned silicon powder body can be spherical or irregular.

[0067] Step 2: Then the cavity is fed with ammonia gas and heated to 800°C to form an inner cladding layer composed of silicon nitride on the surface of the core part composed of silicon powder. The general formula of silicon nitride is SiNx (0.1≤x≤0.8), wherein when the flow rate of ammonia gas is changed from 10 standard cubic centimeters per minute (sccm) to 50 standard cubic centimeters per minute (sccm), X of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com