Nickel aluminum hydrotalcite oxide/quantum dot/nano gold composite film modified electrode and preparation method thereof

A technology of nickel-aluminum hydrotalcite and carbon quantum dots is used in measuring devices, material analysis by electromagnetic means, instruments, etc., which can solve the problems of poor enzyme activity, poor catalysis, and poor nano-gold dispersibility. The effect of stable reaction process, large specific surface area and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

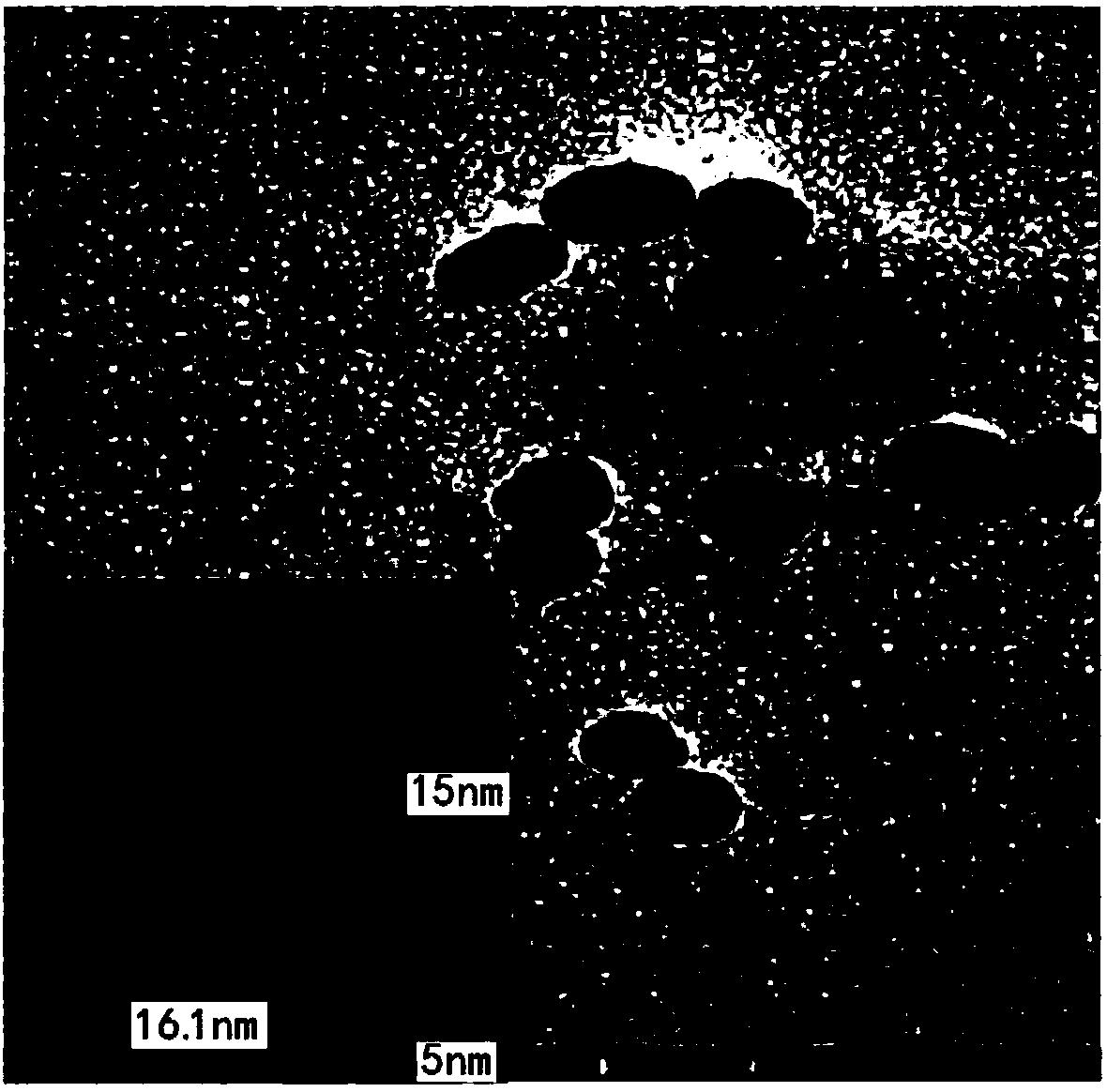

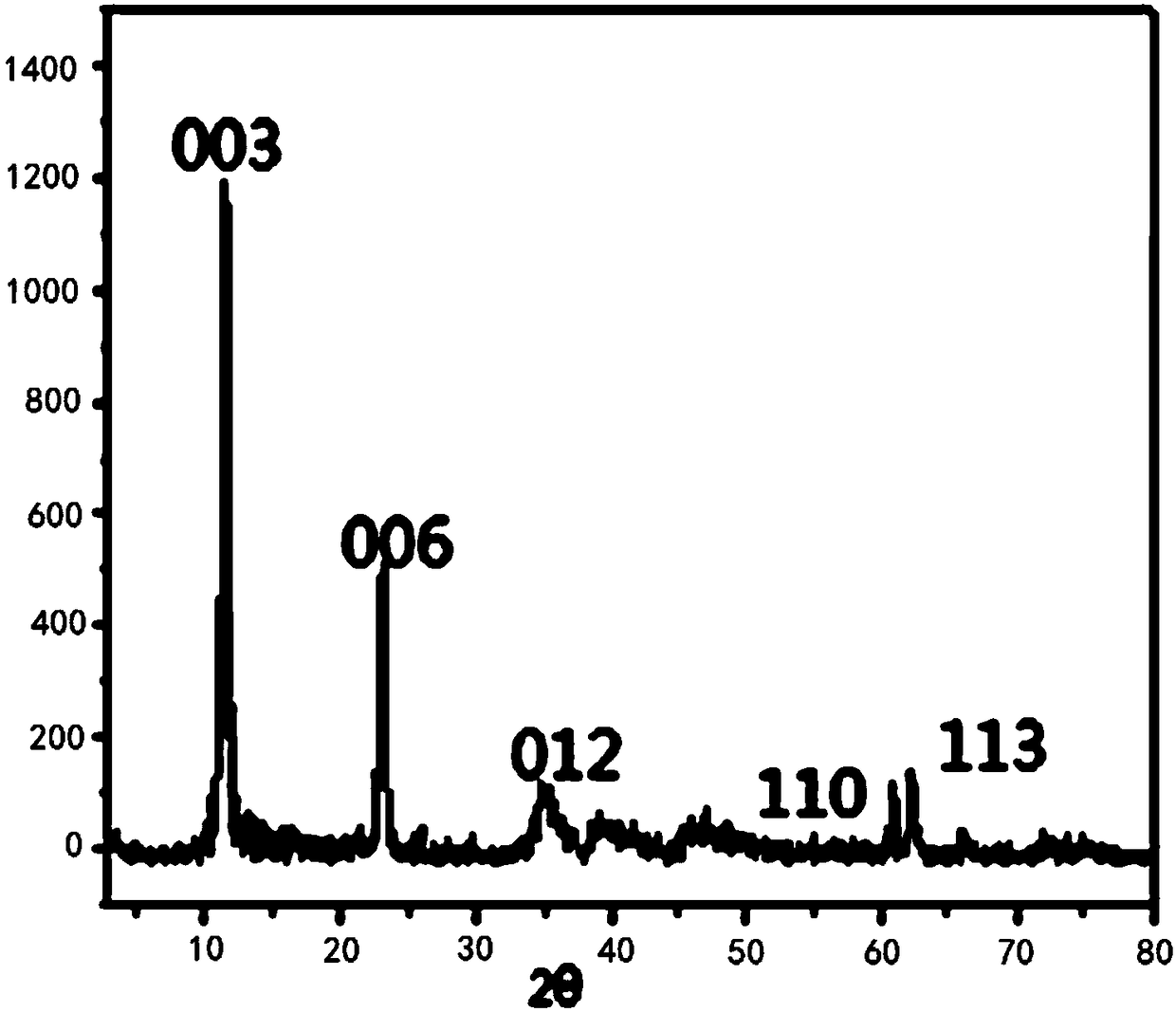

Image

Examples

Embodiment 1

[0052] 1. Preparation of nickel aluminum hydrotalcite oxide (Ni / Al-LDO)

[0053] Weigh 2.0g Ni(NO 3 ) 2 ·6H 2 O and 1.0g Al(NO 3 ) 3 9H 2 O, dissolved in 100mL of deionized water to prepare a nitrate aqueous solution. Weigh 1.0g Na 2 CO 3 and 2.0g of NaOH were dissolved in 50mL of deionized water, stirring continuously to dissolve them all. Transfer all the nitrate aqueous solution to a 250mL three-neck flask, put the flask into a water bath, set the temperature at 65°C, and add Na 2 CO 3 React with an aqueous solution of NaOH at a pH of 10.5 to 11.5, react for 10 hours, filter and wash until neutral, and dry in an oven at 100°C for 12 hours to obtain nickel-aluminum hydrotalcite. Take part of the nickel-aluminum hydrotalcite and put it into a muffle furnace for calcination, the temperature is set at 350°C, and it is calcined for 3 hours to obtain Ni / Al-LDO.

[0054] 2. Preparation of carbon quantum dots (C-dots)

[0055] Step 1: prepare an electrolyte solution; mi...

Embodiment 2

[0067] 1. Preparation of nickel aluminum hydrotalcite oxide (Ni / Al-LDO)

[0068] Weigh 4.0g Ni(NO 3 ) 2 ·6H 2 O and 2.0g Al(NO 3 ) 3 9H 2 O, dissolved in 100mL of deionized water to prepare a nitrate aqueous solution. Weigh 3.0g Na 2 CO 3 and 4.0g of NaOH were dissolved in 50mL of deionized water, stirring continuously to dissolve them all. Transfer all the nitrate aqueous solution to a 250mL three-neck flask, put the flask into a water bath, set the temperature at 65°C, and add Na 2 CO 3 and NaOH aqueous solution to ensure the pH is 10.5-11.5, react for 12 hours, filter and wash until neutral, put it in an oven and dry at 100°C for 12 hours to obtain nickel-aluminum hydrotalcite. Take part of the nickel-aluminum hydrotalcite and put it into a muffle furnace for calcination, the temperature is set at 450° C., and calcine for 5 hours to obtain Ni / Al-LDO.

[0069] 2. Preparation of carbon quantum dots (C-dots)

[0070] Step 1: prepare an electrolyte solution; mix 170...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com