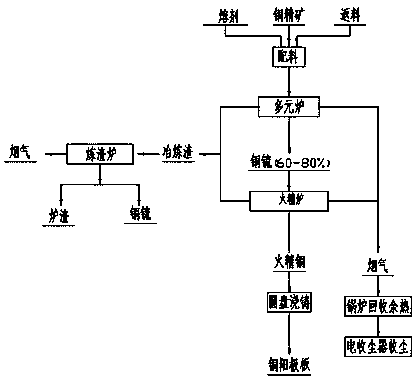

Novel short-process continuous copper smelting device and technology

A short process, copper smelting technology, applied in the direction of improving process efficiency, etc., can solve the problems of high power consumption in the production of electric depletion process, not being recycled, and lengthy flotation process, so as to achieve good promotion and use value and save The effect of manpower and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Multi-element furnace 3: The smelting temperature is 1180°C; the flux is quartz stone, and the amount added is 8% of the total weight of the concentrate; the oxidant is oxygen and air, and the amount added is 142Nm per ton of copper concentrate 3 O2.

[0044] Furnace 1: The smelting temperature is 1200°C; Sulfur: The flux is quartz stone, and its addition amount is 1% of the total weight of the copper matte added; the oxidant is oxygen-enriched air, and cold materials and scrap copper are added to the fine furnace at the same time etc.; after the blowing is completed, the slag discharge operation is carried out first, and the copper production operation is carried out after the slag discharge is completed, and the gas is switched to natural gas and air, and the copper liquid is reduced until the qualified anode copper is produced.

[0045] Slag Smelting Furnace 5: The reaction temperature in Slag Smelting Furnace 5 is 1250°C; the vulcanizing agent is pyrite, the reducin...

Embodiment 2

[0048] Multi-element furnace 3: the smelting temperature is 1200°C; the flux is quartz stone, and its addition amount is 5% of the total weight of the concentrate; the oxidant is oxygen and air, and its addition amount is 155Nm per ton of copper ore 3 O2.

[0049] Pyrofinishing furnace 1: The smelting temperature is 1220°C, the flux is quartz stone, and the amount added is 2% of the total weight of the copper matte added; the oxidant is oxygen-enriched air, and cold material, scrap copper, etc. are added to the pyrofine furnace at the same time; After the blowing is completed, the slag discharge operation is carried out first, and the copper production operation is carried out after the slag discharge is completed. The gas is switched to natural gas and air, and the copper liquid is reduced until the qualified anode copper is produced.

[0050] Slag Smelting Furnace 5: The reaction temperature in Slag Smelting Furnace 5 is 1280°C; the vulcanizing agent is pyrite, the reducing ...

Embodiment 3

[0053] Multi-element furnace 3: The smelting temperature is 1250°C; the flux is quartz stone, and its addition amount is 5% of the total weight of the concentrate; the oxidant is oxygen and air, and its addition amount is 160Nm per ton of copper ore 3 O2.

[0054] Pyrofinishing furnace 1: The smelting temperature is 1250°C; the flux is quartz stone, and its addition amount is 3% of the total weight of copper matte; the oxidizing agent is oxygen-enriched air, and cold material, scrap copper, etc. are added to the pyrofinishing furnace at the same time; After the smelting is completed, the slag discharge operation is carried out first. After the slag discharge is completed, the copper production operation is carried out. The gas is switched to natural gas and air, and the copper liquid is reduced until the qualified anode copper is produced.

[0055] Slag Smelting Furnace 5: The reaction temperature in Slag Smelting Furnace 5 is 1300°C; the vulcanizing agent is pyrite, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com