Laterite-nickel ore RKEF smelting process smoke comprehensive treatment system and method

A technology of laterite nickel ore and treatment system, which is applied in the field of comprehensive flue gas treatment system of laterite nickel ore RKEF smelting process, can solve the problems of high environmental protection pressure, blockage of flue, large maintenance cost, etc., and achieves low environmental protection pressure and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

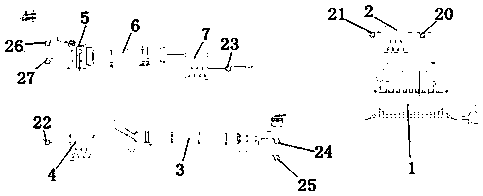

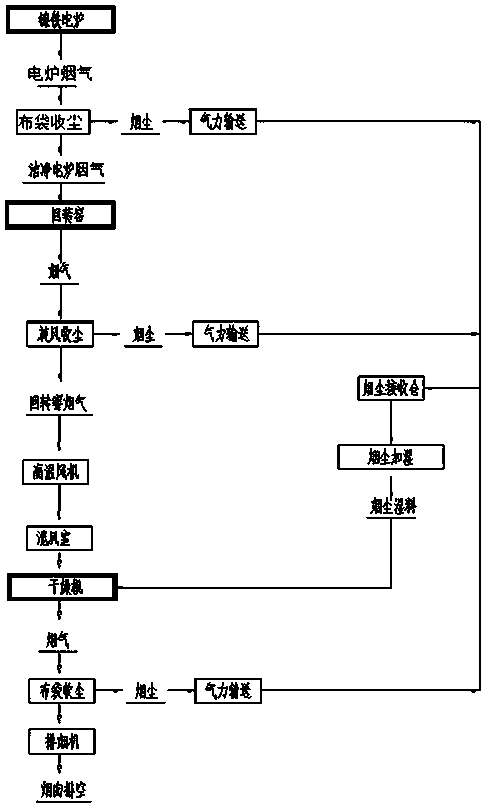

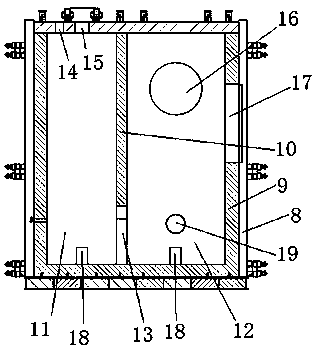

Method used

Image

Examples

Embodiment 1

[0065] (1) The reduction of nickel-iron electric furnace produces electric furnace flue gas, in which the concentration of CO in the electric furnace flue gas is 40% by volume, the temperature of the flue gas is 500°C, and the dust concentration is 35g / Nm 3 ; Firstly, through the water-cooled flue, the temperature of the electric furnace flue gas produced by the nickel-iron electric furnace reduction is lowered to 80°C, and then the first bag filter is used to collect and purify the electric furnace flue gas, and the dust concentration in the flue gas is 3 , the purified electric furnace flue gas is blown into the rotary kiln by a pressurized fan, and the electric furnace flue gas is used as one of the fuels of the rotary kiln, and the negative pressure in the nickel-iron electric furnace is adjusted to 1 Pa by a pressure regulating fan;

[0066] (2) Use a cyclone dust collector to collect dust from the flue gas generated by the rotary kiln, wherein the temperature of the flue g...

Embodiment 2

[0070] (1) The reduction of nickel-iron electric furnace produces electric furnace flue gas, in which the CO concentration in the electric furnace flue gas is 60% by volume, the flue gas temperature is 600°C, and the dust concentration is 35g / Nm 3 ; Firstly, through the water-cooled flue, the temperature of the electric furnace flue gas produced by the nickel-iron electric furnace reduction is lowered to 100°C, and then the first bag filter is used to collect and purify the electric furnace flue gas, and the dust concentration in the flue gas is 3 , the purified electric furnace flue gas is blown into the rotary kiln by a pressurized fan, and the electric furnace flue gas is used as one of the fuels of the rotary kiln, and the negative pressure in the nickel-iron electric furnace is adjusted to 10 Pa by a pressure regulating fan;

[0071] (2) Use a cyclone dust collector to collect dust from the flue gas generated by the rotary kiln, wherein the temperature of the flue gas from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com