Method for continuously synthesizing oligo-isomalto-oligosaccharides

A technology of polysaccharide and chitosan, which is applied in the field of immobilized cell catalysis, can solve the problems of high production cost of IMOs and the inability to obtain α-glucosidase, etc., and achieve improved recycling efficiency, good recycling characteristics, and simple method effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

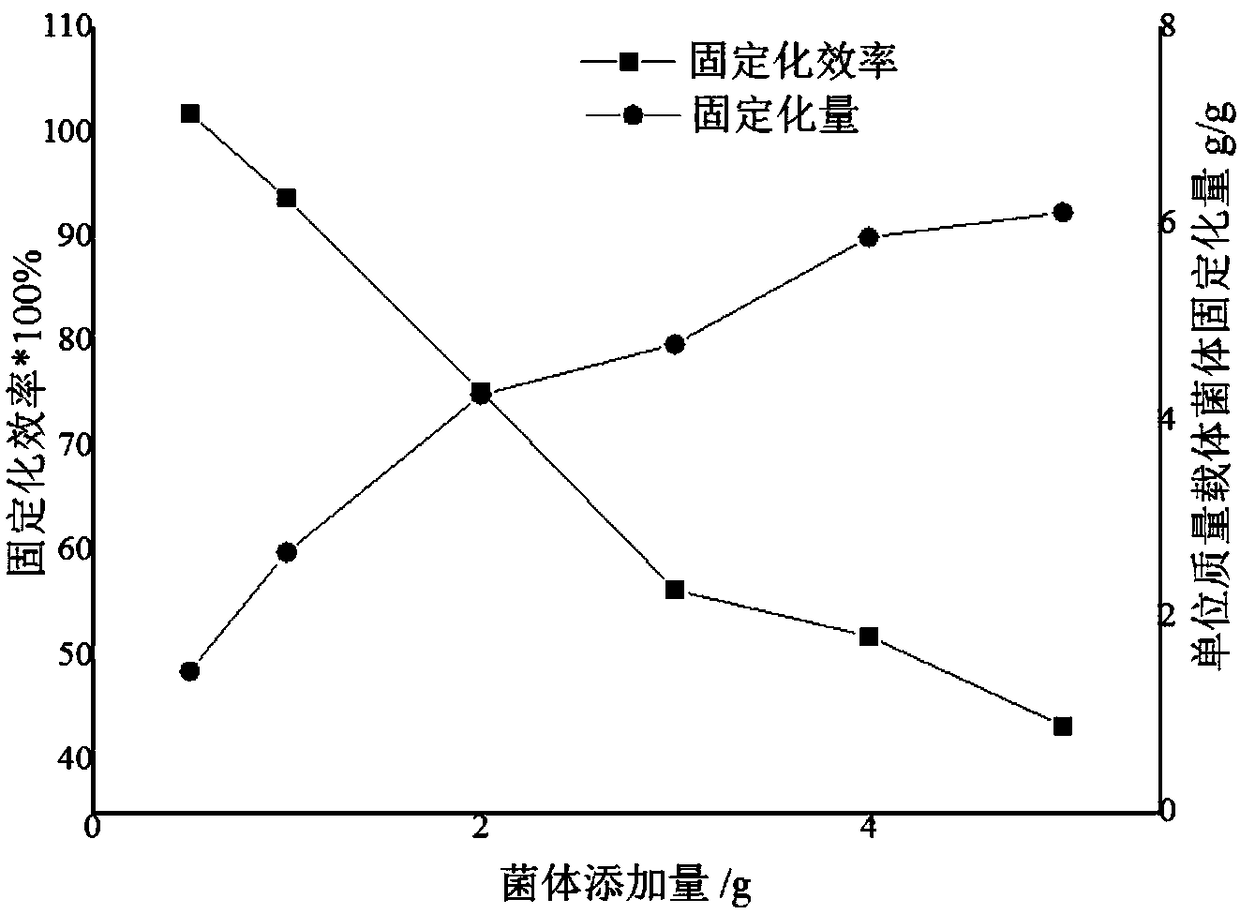

[0052] Example 1 Immobilization of Pichia pastoris with α-glucosidase displayed on its surface

[0053] 1. Preparation of immobilized recombinant yeast strains

[0054] The details are as follows: first, 1 g of chitosan is added to 250 mL of 5% (m / v) aqueous acetic acid solution, fully dissolved. Then add 250mL double distilled water in chitosan sol and dilute, add the FeSO of 100mL3.6% (w / v) behind 4 ·7H 2 O aqueous solution. At this time, the solution was acidic, with pH10, and dark green flocs were formed. Take 250mL of the above flocculation solution in a 1000mL beaker, and place it in a microwave oven at 700W for 20min. To obtain black magnetic microspheres coated with chitosan with high paramagnetism, the carrier was washed three times with an aqueous solution with a pH>7.0. After homogenization, paste-like magnetic particles were obtained. Add 20 mL of 5% (v / v) glutaraldehyde solution to every 20 mL of magnetic particle paste, react on a shaker at 90 rpm (4000i con...

Embodiment 2

[0059] Continuous catalytic synthesis of IMOs in the fixed bed of embodiment 2

[0060] 1. Design of fixed bed bioreactor

[0061] A fixed-bed bioreactor was designed and manufactured, and the reactor was made of transparent acrylic tube. The reactor consists of three parts: the upper and lower plugs, the substrate uniform distribution module, and the immobilized cell catalyst filling module. The immobilized cell catalyst filling module is provided with a sampling port. The physical structure of the reactor is as Figure 4 As shown, the inner diameter is 60mm, and the filling layer can be spliced with two specifications of modules with a height of 50mm / 100mm to study the influence of different filling amounts of immobilized bacteria on product distribution and product yield. The upper and lower layers of the bed are filled with 15 g of immobilized bacteria. There are filter membranes between different modules to prevent the leakage of immobilized bacteria. The process f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com