Concrete-powder-containing gypsum based leveling putty and preparation method thereof

A technology based on gypsum and concrete powder, which is applied in the direction of fireproof coatings, filling slurry, etc., which can solve the problems of short construction time, high construction requirements, and long maintenance time, and achieve the effects of saving construction period, low labor intensity, and short maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

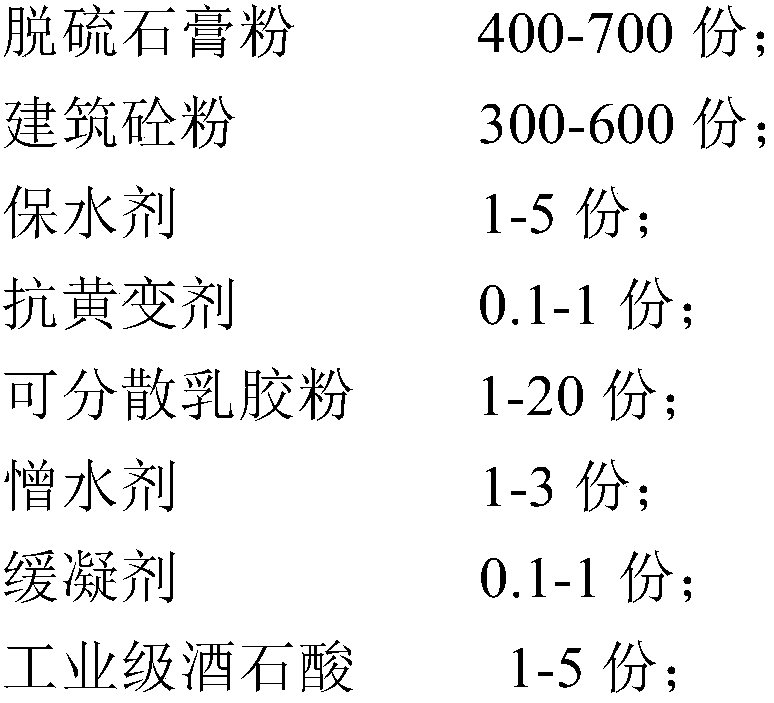

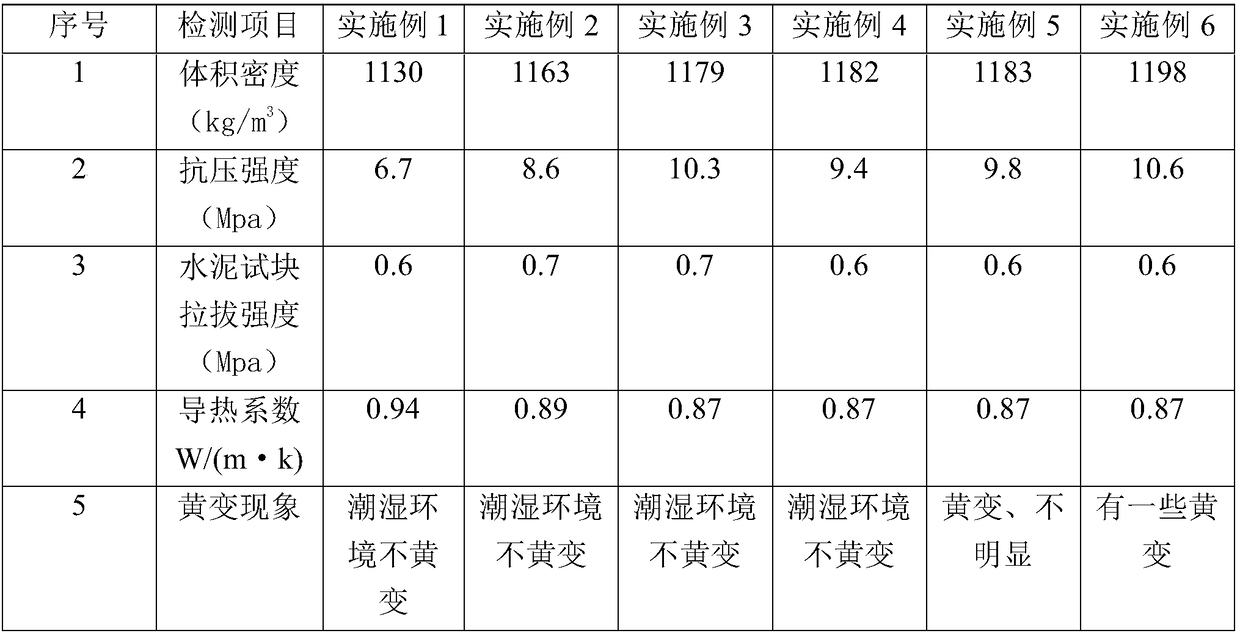

[0028] A gypsum-based leveling putty with concrete powder, comprising the following raw materials in parts by mass: 500 kg of desulfurized gypsum powder of 325 mesh; 500 kg of building concrete powder of 50-200 mesh; 2 kg of sodium hydroxypropyl methylcellulose; 0.1 kg of calcium formate; 120 mesh styrene-acrylic latex powder 15kg; silane-based water repellent 2kg; sodium citrate 1kg; industrial grade tartaric acid 2kg; carboxymethyl starch 1kg; zinc sulfate 2kg; Kasong dry powder fungicide 1kg;

[0029] Sulfur gypsum powder, building concrete powder, sodium hydroxypropyl methylcellulose, calcium formate, styrene-acrylic latex powder, silane-based water repellent, sodium citrate, industrial grade tartaric acid, carboxymethyl starch, zinc sulfate and Kasong dry powder fungicides are mixed and stirred evenly to obtain desulfurized gypsum-based leveling putty.

Embodiment 2

[0031] A gypsum-based leveling putty with concrete powder, comprising the following raw materials in parts by mass: 600 kg of desulfurized gypsum powder of 325 mesh; 400 kg of building concrete powder of 50-200 mesh; 2 kg of sodium hydroxypropyl methylcellulose; 0.1 kg of calcium formate; 120 mesh styrene-acrylic latex powder 15kg; silane-based water repellent 2kg; sodium citrate 1kg; industrial grade tartaric acid 2kg; carboxymethyl starch 1kg; zinc sulfate 2kg; Kasong dry powder fungicide 1kg;

[0032] Sulfur gypsum powder, building concrete powder, sodium hydroxypropyl methylcellulose, calcium formate, styrene-acrylic latex powder, silane-based water repellent, sodium citrate, industrial grade tartaric acid, carboxymethyl starch, zinc sulfate and Kasong dry powder fungicides are mixed and stirred evenly to obtain desulfurized gypsum-based leveling putty.

Embodiment 3

[0034] A gypsum-based leveling putty with concrete powder, comprising the following raw materials in parts by mass: 700 kg of desulfurized gypsum powder of 325 mesh; 300 kg of building concrete powder of 50-200 mesh; 2 kg of sodium hydroxypropyl methylcellulose; 0.1 kg of calcium formate; 120 mesh styrene-acrylic latex powder 15kg; silane-based water repellent 2kg; sodium citrate 1kg; industrial grade tartaric acid 2kg; carboxymethyl starch 1kg; zinc sulfate 2kg; Kasong dry powder fungicide 1kg;

[0035] Sulfur gypsum powder, building concrete powder, sodium hydroxypropyl methylcellulose, calcium formate, styrene-acrylic latex powder, silane-based water repellent, sodium citrate, industrial grade tartaric acid, carboxymethyl starch, zinc sulfate and Kasong dry powder fungicides are mixed and stirred evenly to obtain desulfurized gypsum-based leveling putty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com