A surface-etched magnesium-aluminum-based layered double hydroxide modifier, ultraviolet aging-resistant asphalt and preparation method thereof

A double hydroxide, surface etching technology, applied in building structures, buildings, building components, etc., can solve the problems of easy agglomeration and poor asphalt compatibility, avoid agglomeration, improve compatibility, and improve dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

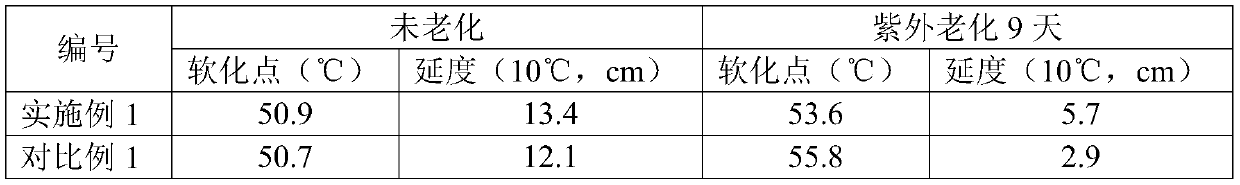

Embodiment 1

[0022] modifier

[0023] A surface etching magnesium-aluminum-based layered double hydroxide modifier, the preparation method of which comprises the following steps: configuring deionized water and nitric acid to form an etching solution with a concentration of 0.1mol / L; and then mixing the etching solution with magnesium The aluminum-based layered double hydroxide is reacted at 50°C for 70 minutes at a mass ratio of 100:1. After the reaction is completed, the reactant is filtered and washed 3 times under reduced pressure, and then dried in an oven at a temperature of 70°C for 24 hours. , take out the dry solid, pulverize it in a high-speed pulverizer, and pass through a 200-mesh sieve to obtain a surface-etched magnesium-aluminum-based layered double hydroxide modifier.

[0024] UV-resistant asphalt

[0025] The surface-etched magnesium-aluminum-based layered double hydroxide modifier obtained in this example is applied to the preparation of UV-resistant aging asphalt, which...

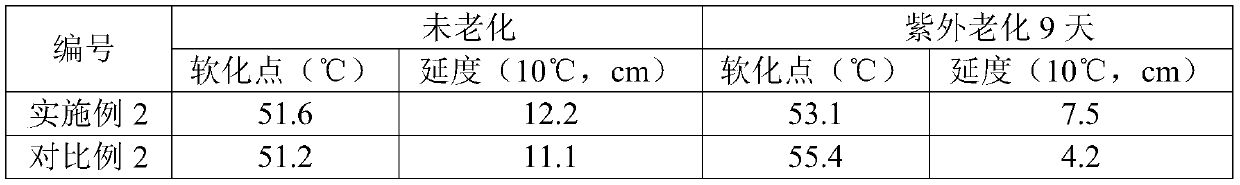

Embodiment 2

[0031] modifier

[0032] A surface etching magnesium-aluminum-based layered double hydroxide modifier, the preparation method of which comprises the following steps: configuring deionized water and sulfuric acid into an etching solution with a concentration of 0.5mol / L; then mixing the etching solution with magnesium The aluminum-based layered double hydroxide is reacted at 50°C for 80 minutes at a mass ratio of 80:1. After the reaction is completed, the reactant is filtered and washed 3 times under reduced pressure, and then dried in an oven at a temperature of 70°C for 24 hours. , take out the dry solid, pulverize it in a high-speed pulverizer, and pass through a 200-mesh sieve to obtain a surface-etched magnesium-aluminum-based layered double hydroxide modifier.

[0033] UV-resistant asphalt

[0034]The surface-etched magnesium-aluminum-based layered double hydroxide modifier obtained in this example is applied to the preparation of UV-resistant aging asphalt, which specif...

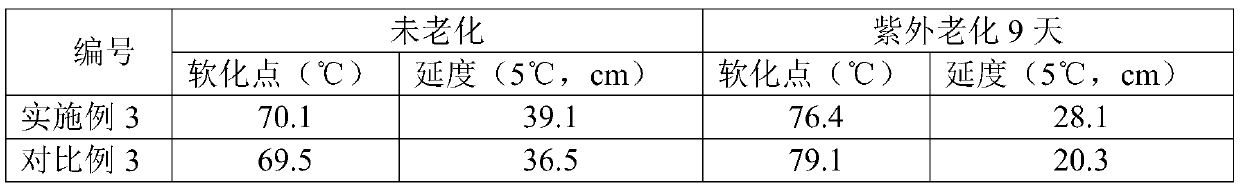

Embodiment 3

[0040] modifier

[0041] A surface etching magnesium-aluminum-based layered double hydroxide modifier, the preparation method of which comprises the following steps: deionized water and nitric acid are configured to form an etching solution with a concentration of 0.3mol / L; then the etching solution is mixed with magnesium The aluminum-based layered double hydroxide is reacted at 60°C for 60 minutes at a mass ratio of 100:1. After the reaction is completed, the reactant is filtered and washed 3 times under reduced pressure, and then dried in an oven at a temperature of 70°C for 24 hours. , take out the dry solid, pulverize it in a high-speed pulverizer, and pass through a 200-mesh sieve to obtain a surface-etched magnesium-aluminum-based layered double hydroxide modifier.

[0042] UV-resistant asphalt

[0043] The surface-etched magnesium-aluminum-based layered double hydroxide modifier obtained in this example is applied to the preparation of UV-resistant aging asphalt, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com