Low-temperature sludge drying system based on multi-stage heat utilization

A sludge and low-temperature technology, applied in the field of sludge low-temperature drying system, can solve the problems of reduced drying efficiency, increased drying cost, and low temperature of drying medium, so as to reduce the generation of pollutants, improve heat utilization efficiency, Effect of reducing drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

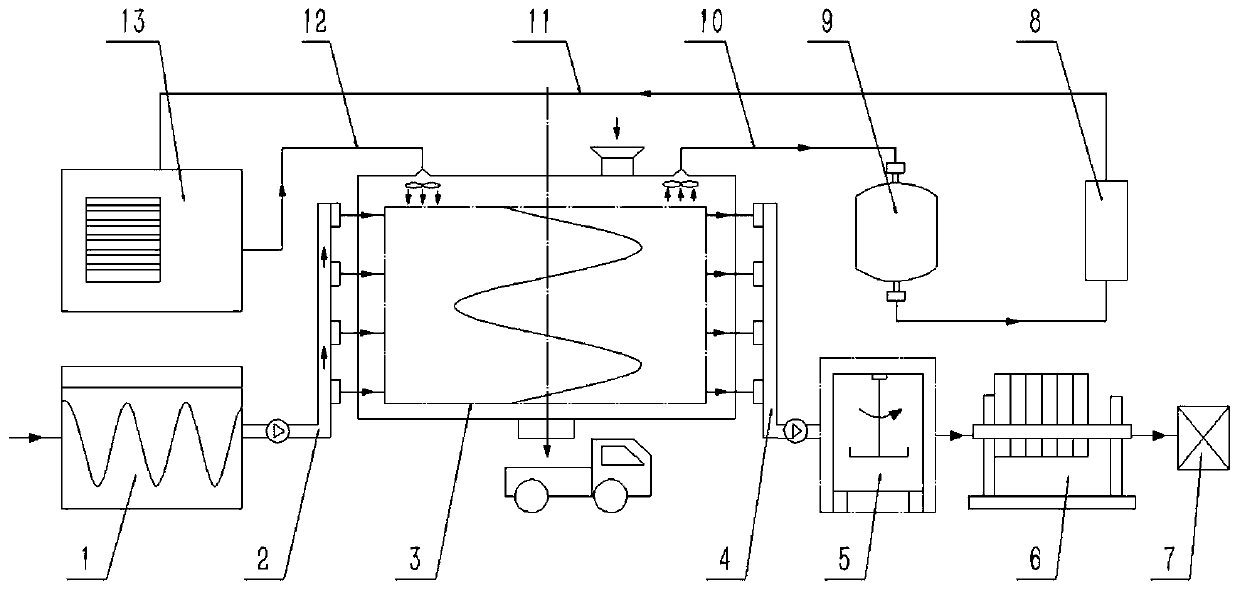

[0046] A disc-type sludge low-temperature drying system based on multi-stage heat utilization uses resistance wire heating as the heating method, and calcium oxide reagent is added as a conditioning agent during conditioning. figure 1 For the schematic diagram of the whole system, figure 2 It is a partial schematic diagram of Example 1. The whole system includes a heat treatment device, a diversion device, a dehydration device, a drying device, a low-temperature drying device and an exhaust gas treatment device; the heat treatment device 1 is provided with a resistance wire 101, an automatic temperature control system 102 and a feed inlet 103; The diversion device includes a diversion pipeline 1 2 and a diversion pipeline 2 4, both of which are provided with 4 branch pipes, which are symmetrically arranged on both sides of the drying device. The dehydration device includes a mixing tank 5, a plate and frame filter press 6 and a pulverizer 7; the upper part of the drying devi...

Embodiment 2

[0049] A belt-type sludge low-temperature drying system based on multi-stage heat utilization uses solar energy as a heating method, and the sludge does not need to be conditioned and directly dehydrated mechanically. figure 1 For the schematic diagram of the whole system, image 3 It is a partial schematic diagram of Example 2. The whole system includes a heat treatment device, a diversion device, a dehydration device, a drying device, a low-temperature drying device and an exhaust gas treatment device; the heat treatment device 1 is provided with a feed inlet three 104, an automatic temperature control system two 105 and a solar collector 106 The diversion device mainly includes a diversion pipeline 2 and a diversion pipeline 2 4, both of which are provided with 4 branch pipes, and are symmetrically arranged on both sides of the drying device. The dehydration device is composed of a plate and frame filter press 6 and a pulverizer 7 (because no conditioning is required, the ...

Embodiment 3

[0052] A paddle-type sludge low-temperature drying system based on multi-stage heat utilization uses microwave heat treatment as the heating method, and the sludge is conditioned with wood chips before being mechanically dehydrated. figure 1 For the schematic diagram of the whole system, Figure 4 It is a partial schematic diagram of Example 3. The whole system includes a heat treatment device, a diversion device, a dehydration device, a drying device, a low-temperature drying device and an exhaust gas treatment device; the heat treatment device 1 is provided with a feed inlet 5 107, an automatic temperature control system 3 108 and a microwave conditioner 109; The diversion device is mainly diversion pipeline one 2 and diversion pipeline two 4, both of which are provided with a branch pipe, and are symmetrically arranged on both sides of the drying device. The dehydration device includes a mixing tank 5, a plate and frame filter press 6 and a pulverizer 7; the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com