A kind of arylated graphene film and its preparation method, a kind of arylated graphene barrier film and its preparation method

A technology of barrier film and graphene, which is applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor hydrophobicity of water and oxygen barrier film, poor hydrophobicity and UV resistance of barrier film, and avoid compatibility Poor, good UV resistance, effect of improving barrier ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

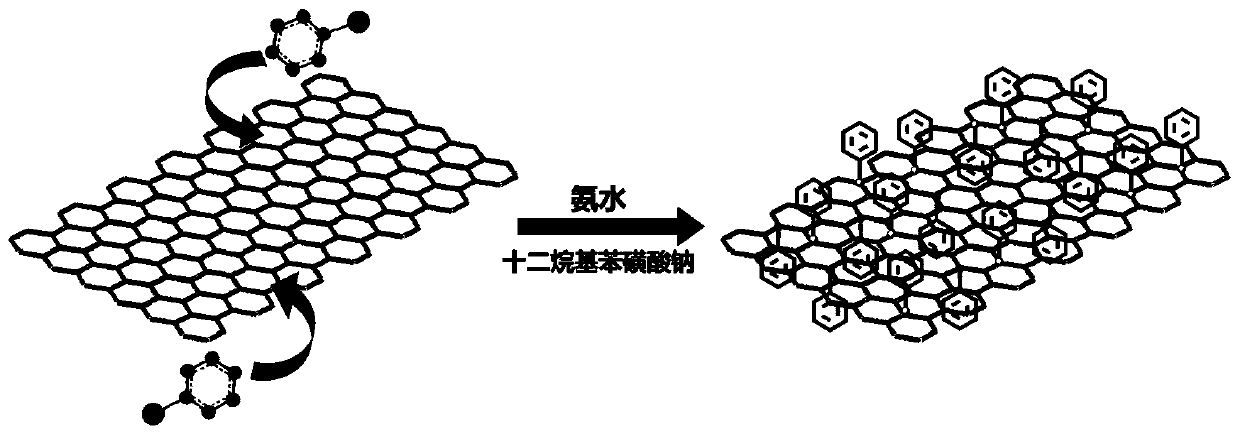

[0052] The preparation method of the arylated graphene film provided by the invention comprises the following steps:

[0053] (1) grow a graphene film on a metal substrate by vapor deposition;

[0054] (2) Place the graphene film obtained in step (1) and the halogenated aromatic hydrocarbon compound in ammonia water to heat and react. After the reaction is completed, wash, centrifuge, suction filter and vacuum dry to obtain the arylated graphene film.

[0055] Further, the heating reaction temperature in step (2) is 60-120°C, the heating time is 12-72 hours, and the vacuum drying temperature is 60-100°C.

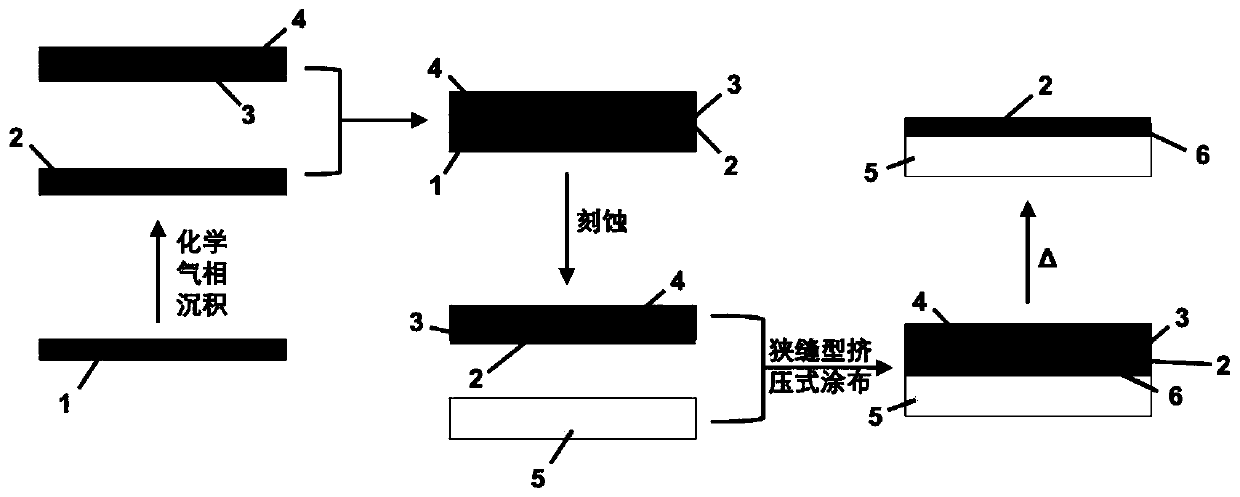

[0056] The preparation method of the arylated graphene barrier film provided by the invention comprises the following steps:

[0057] (1) Lay the arylated graphene film with copper foil and the transfer substrate with thermal release adhesive together by rolling, and then soak the above composite material in a mixture of hydrochloric acid / hydrogen peroxide Solvent in the w...

Embodiment 1

[0068] The invention provides an arylated graphene film, the film includes graphene, and the surface of the graphene is grafted with an aromatic compound. The present invention also provides an arylated graphene barrier film, which sequentially includes an arylated graphene film, a barrier glue and a substrate layer.

[0069] 1. Preparation of arylated graphene films

[0070] Using a conventional vapor deposition method, a graphene film is grown on 100g copper foil, and then the graphene / copper foil (graphene content is 10g) is placed in an ammonia tank and 10g 1-brominated benzene is added, and the reaction is heated at 100°C After 24 hours, filter, wash with deionized water, acetone, chloroform, and ethanol respectively, centrifuge, suction filter, and vacuum-dry at 100°C to obtain 19.8 g of arylated graphene with copper foil, with a yield of 99%. Wherein the thickness of the metal substrate is 15 microns.

[0071] 2. Preparation of arylated graphene barrier film

[0072]...

Embodiment 2

[0074] The arylated graphene film and the arylated graphene barrier film provided in Example 1.

[0075] 1. Preparation of arylated graphene films

[0076] Using a conventional vapor deposition method, a graphene film is grown on 100g of copper foil, then the graphene / copper foil (graphene content is 10g) is placed in an ammonia tank and 5g of 1-brominated benzene is added, and the reaction is heated at 100°C After 24 hours, filter, wash with deionized water, acetone, chloroform, and ethanol respectively, centrifuge, suction filter, and vacuum-dry at 100°C to obtain 13.5 g of arylated graphene with copper foil, with a yield of 90%. Wherein the thickness of the metal substrate is 15 microns.

[0077] 2. Preparation of arylated graphene barrier film

[0078] The arylated graphene film with copper foil and the transfer substrate with thermal release adhesive are laminated together flatly by rolling, and then the above composite material is soaked in a water tank containing a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com