Preparation method for ceramic plastic composite structure part and shell of electronic equipment

A composite structure, ceramic plastic technology, applied in the field of electronic equipment shell, ceramic plastic composite structural parts preparation, can solve the problems of high injection pressure, ceramic layer burst, etc., to improve bonding strength, improve bonding strength, excellent comprehensive mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

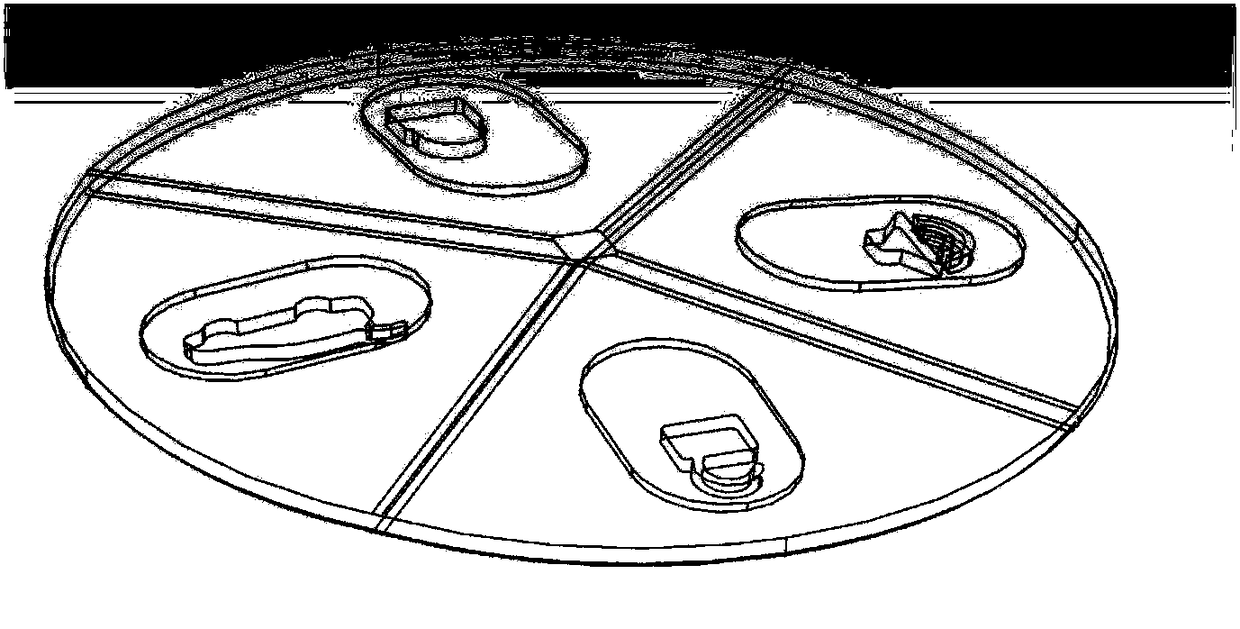

Image

Examples

Embodiment 1

[0034] Preparation process of drop-resistant ceramic plastic mobile phone shell

[0035]Add 5kg of alumina ceramic powder with a D50 of 0.7um, 25g of water-based polybutylacrylate and 12.5kg of deionized water into a stirring mill and stir thoroughly for 2 hours, then spray dry at 260°C to obtain granulated powder, and add the granulated powder to the dry pressing mold According to 1200kg.f / cm 2 The pressure is pressed to obtain the blank of the ceramic part, and the cold isostatic pressing is shaped, and then stacked. The temperature is raised to 600°C at 1°C / min and kept for 2 hours. .

[0036] Soak the ceramic structure blank in a 0.3mol / L hydrofluoric acid solution at a temperature of 95°C for 30 minutes, take it out, rinse it, and then perform CNC machining to remove the surface machining allowance and flexibly polish the outer surface to obtain a ceramic structure. The surface is coated with a layer of 50um polyisocyanate glue for later use.

[0037] Weigh 200g of cap...

Embodiment 2

[0040] Preparation process of drop-resistant ceramic plastic watch case

[0041] Weigh 10g of stearic acid, 2kg of zirconia ceramic powder with a D50 of 0.5um, and 80g of No. 58 paraffin wax, add the weighed raw materials to a 3L internal mixer, and banbury at 150°C for 1h to obtain the feed, and add the feed to the injection molding In the machine, the back cover of the watch is obtained by injection molding at 150MPa, stacked and placed in a degreasing furnace, and the temperature is slowly raised to 170°C at a rate of 0.2°C / min. Press 1°C / min, raise the temperature to 450°C for two hours, then raise the temperature to 650°C at 1°C / min, then raise the temperature to 1500°C at a rate of 5°C / min and keep it for 2 hours, then cool down to 950°C at 5°C / min. Cool to obtain a watch blank.

[0042] Soak the blank in a 3mol / L hydrofluoric acid solution at a temperature of 60°C for 10 minutes, take it out and rinse it off, then go through CNC machining to remove the surface machinin...

Embodiment 3

[0046] Preparation process of drop-resistant ceramic plastic car key press keyboard

[0047] Weigh 9g of stearic acid, 2kg of silicon oxide powder with a D50 of 1um, and 80g of No. 58 paraffin wax, add the weighed raw materials to a 3L internal mixer, and banbury at 150°C for 1h to obtain the feed, and put the feed into the injection molding machine Injection molding at 150MPa to get the car key keypad green body, put it into the degreasing furnace and slowly raise the temperature to 170°C at a rate of 0.2°C / min, keep it warm for 20 hours and then cool it with the furnace, then stack the green body into the sintering Press 1°C / min in the furnace, heat up to 450°C for two hours, then heat up to 650°C at 1°C / min, then raise the temperature to 1250°C at a rate of 5°C / min and hold for 2 hours, then cool down with the furnace to obtain the car key keypad ceramic blank .

[0048] Soak the blank in a 1.5mol / L hydrofluoric acid solution at a temperature of 70°C for 20 minutes, take i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com