Natural gas demercuration adsorbent and preparation method thereof

An adsorbent, natural gas technology, applied in chemical instruments and methods, gas fuels, other chemical processes, etc., can solve the problems of unstable pore volume and pore size, large amount of mercury removal agent, slow mercury removal rate, etc. The effect of improving mercury removal speed, rapid and stable mercury removal, and increasing mercury capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

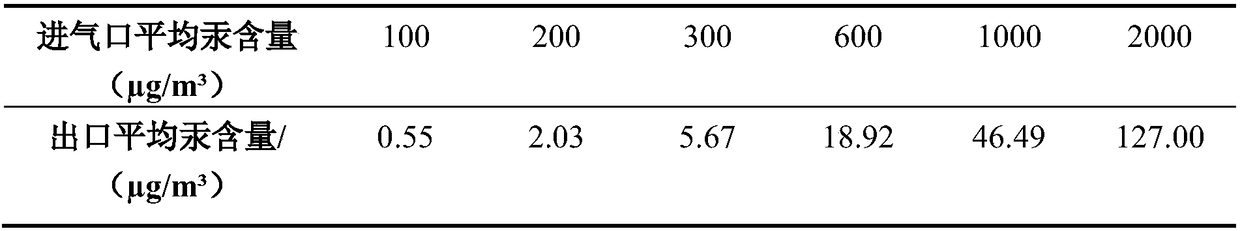

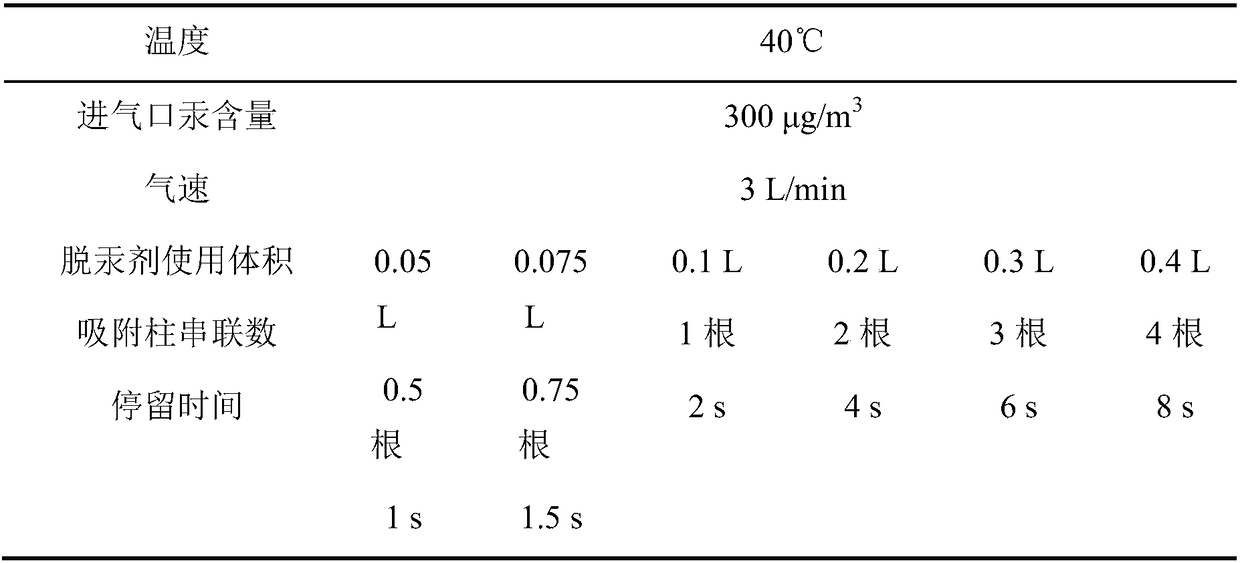

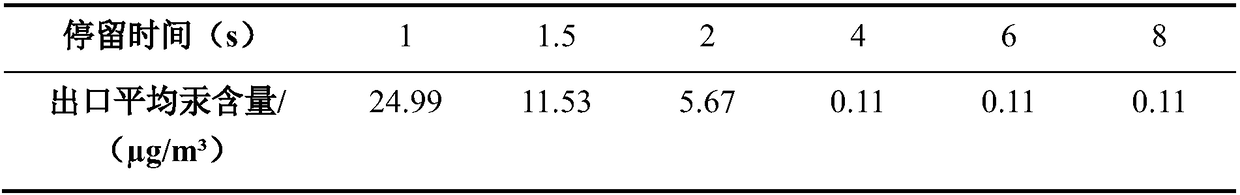

[0022] (1) Mercury removal adsorbent Al 2 o 3 Preparation of -AC-CuS-S and its determination of mercury capacity

[0023] Take 90g of 3~4mm Al 2 o 3 -AC composite carrier particles, dried at 105°C to constant weight. Will Al 2 o 3 -AC composite support was impregnated in 150mL CS with 5% S content 2 The solution was soaked for 2 hours, filtered and baked in an oven at 50°C for 3 hours, and the calculated elemental sulfur loading was 4.39g. Then use Cu 2+ 150mL Cu(NO 3 ) 2 ·3H 2 O solution impregnated the above-mentioned sulfur-containing carrier for 2h, filtered and dried, and calculated Cu 2+ The loading was 9.24 g. Take Na again 2 S·9H 2 Add O into water, dissolve and prepare 150mL Na with a concentration of 65% at 80°C 2 S·9H 2 O solution, will be impregnated with Cu 2+ The composite support impregnated in the above Na 2 S solution for 2h, filtered, washed with water and dried to obtain Al 2 o 3 -AC-CuS-S adsorbent for mercury removal, the calculated CuS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com