A kind of dual function device based on gete and preparation method thereof

A dual-function, device technology, applied in the direction of electrical components, etc., can solve the problems of reducing the complexity of the storage density process, achieve good tolerance, low operating current, and increase the storage density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

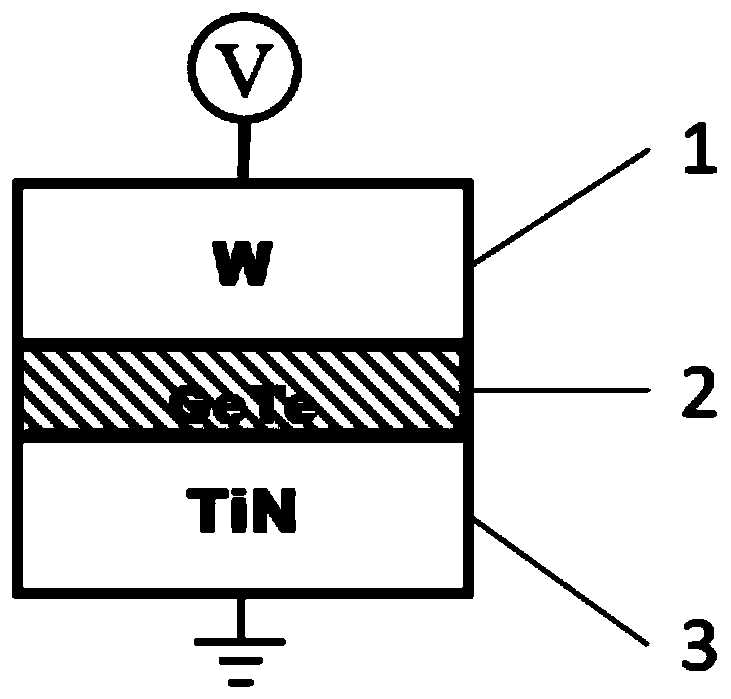

[0037] Such as figure 1 As shown, a GeTe-based bifunctional device in this embodiment includes a three-layer structure: a top electrode 1 , a thin film dielectric layer 2 and a bottom electrode 3 .

[0038] The bottom electrode 3 is made of TiN with a thickness of 200nm and a rectangular shape with a side length of 0.4 μm.

[0039] The GeTe thin film dielectric layer 2 has a thickness of 20 nm, a rectangular shape, and a side length of 0.4 μm.

[0040] The top electrode 1 is made of W with a thickness of 250 nm and a rectangular shape with a side length of 0.4 μm.

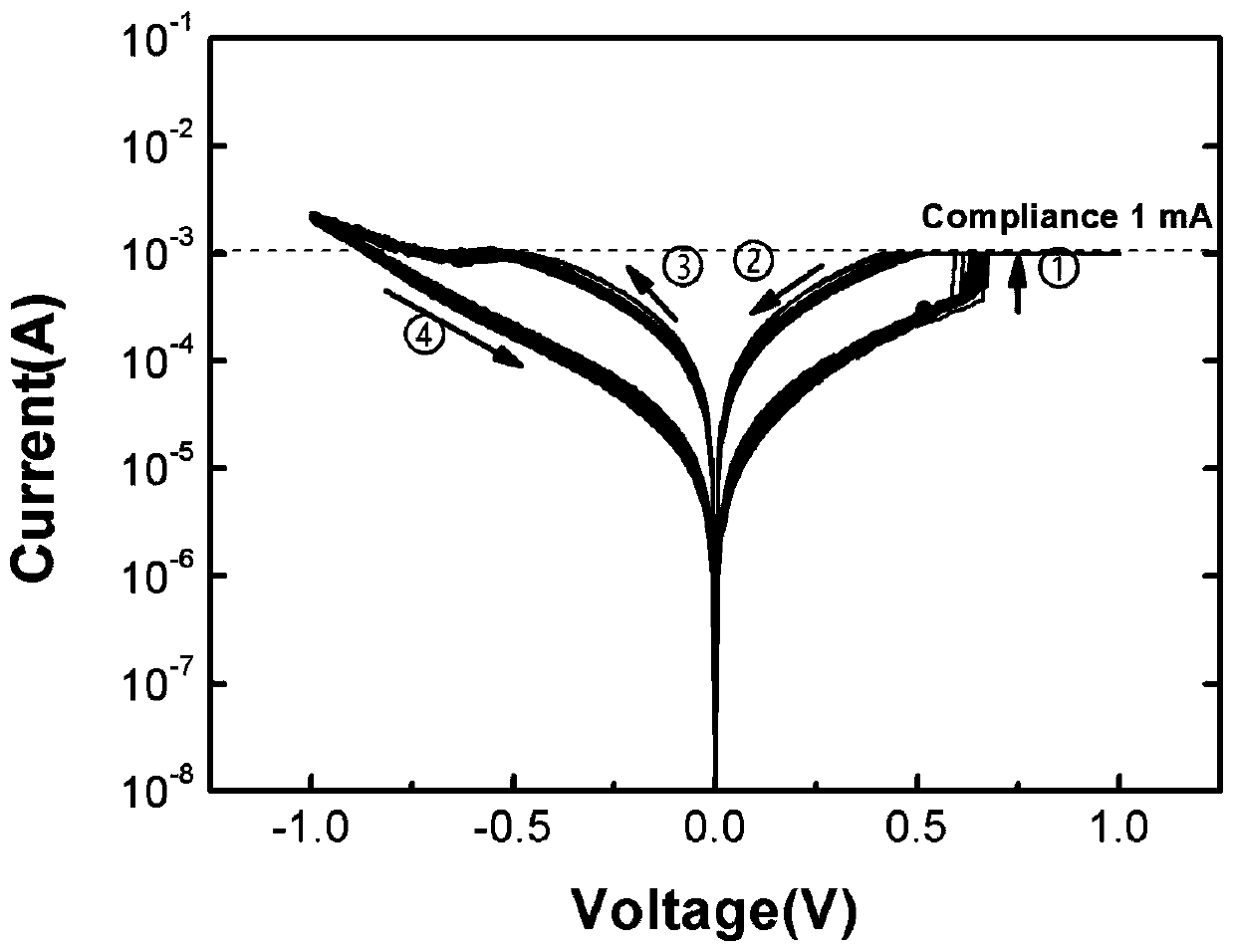

[0041] When realizing the conventional resistive switching function, the operating current limit range of the device is 1mA.

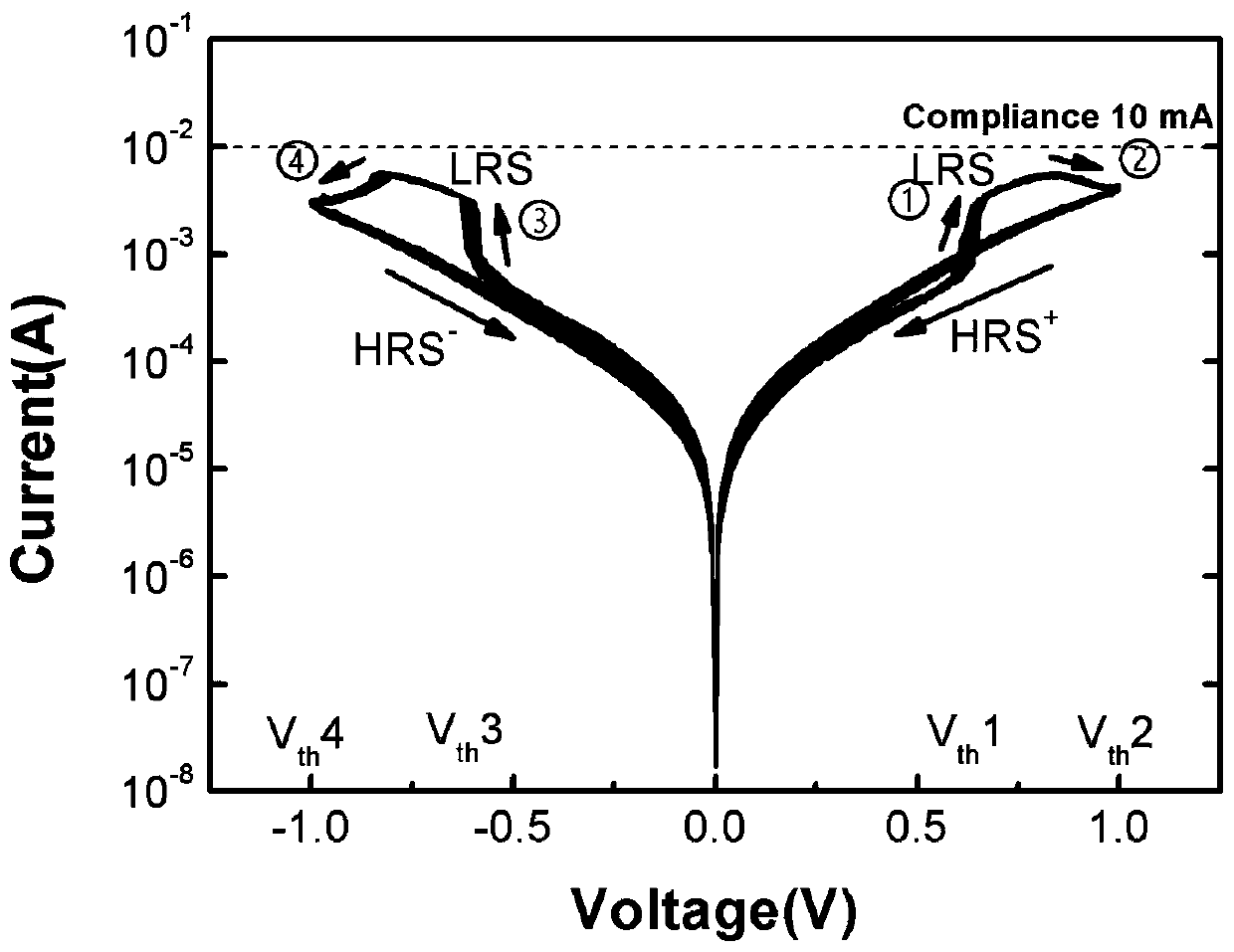

[0042] When realizing the complementary resistive switching function, the operating current limit range of the device is 10mA.

[0043] The preparation method of the GeTe-based dual-function device described above in this embodiment includes the following steps:

[0044] The bottom electr...

Embodiment 2

[0049] A GeTe-based dual-function device in this embodiment includes a three-layer structure: a top electrode, a thin-film dielectric layer, and a bottom electrode.

[0050] The bottom electrode is made of TiN with a thickness of 200 nm and a rectangular shape with a side length of 0.6 μm.

[0051] The dielectric layer of the GeTe thin film has a thickness of 20 nm and a rectangular shape with a side length of 0.6 μm.

[0052] The top electrode is made of W with a thickness of 250 nm and a rectangular shape with a side length of 0.6 μm.

[0053] When realizing the conventional resistive switching function, the operating current limit range of the device is 1mA.

[0054] When realizing the complementary resistive switching function, the operating current limit range of the device is 10mA.

[0055] The preparation method of the GeTe-based dual-function device described above in this embodiment includes the following steps:

[0056] The bottom electrode is prepared on the base...

Embodiment 3

[0061] A GeTe-based dual-function device in this embodiment includes a three-layer structure: a top electrode, a thin-film dielectric layer, and a bottom electrode.

[0062] The bottom electrode is made of TiN with a thickness of 200 nm and a rectangular shape with a side length of 0.8 μm.

[0063] The dielectric layer of the GeTe thin film has a thickness of 20 nm and a rectangular shape with a side length of 0.8 μm.

[0064] The top electrode is made of W with a thickness of 250 nm and a rectangular shape with a side length of 0.8 μm.

[0065] When realizing the conventional resistive switching function, the operating current limit range of the device is 1mA.

[0066] When realizing the complementary resistive switching function, the operating current limit range of the device is 10mA.

[0067] The preparation method of the above-mentioned GeTe-based dual-function device comprises the following steps:

[0068] The bottom electrode is prepared on the base; a GeTe thin film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com