A gete-based complementary resistive memory and its preparation method

A resistive memory, complementary technology, applied in electrical components and other directions, can solve problems such as cross-talk of resistive devices, and achieve the effects of easy high-density integration, low manufacturing cost, and easy control of the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

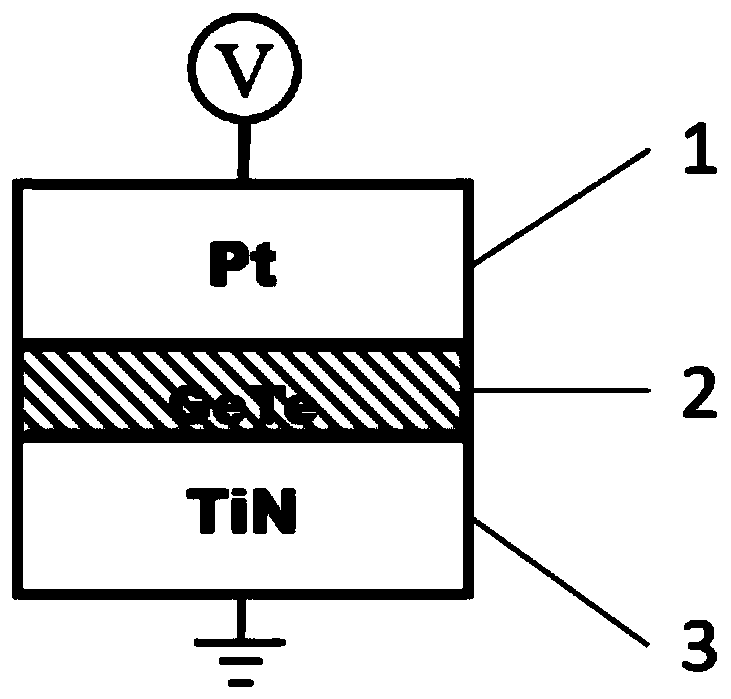

[0032] Such as figure 1 As shown, a GeTe-based complementary resistive variable memory of the present embodiment includes a bottom conductive electrode 3; a GeTe thin film dielectric layer 2 on the upper surface of the bottom conductive electrode; a GeTe thin film dielectric layer on the upper surface Top conductive electrode 1;

[0033] The bottom conductive electrode 3 is made of TiN, has a thickness of 200nm, is rectangular in shape, and has a side length of 0.4 μm;

[0034] The GeTe thin film dielectric layer 2 has a thickness of 20 nm, a rectangular shape, and a side length of 0.4 μm;

[0035] The top conductive electrode 1 is made of Pt, has a thickness of 250 nm, and is rectangular in shape with a side length of 0.4 μm.

[0036] The preparation method of the above-mentioned GeTe-based complementary resistive memory comprises the following steps:

[0037] The bottom conductive electrode is prepared on the base; a GeTe thin film dielectric layer is prepared on the uppe...

Embodiment 2

[0042] A GeTe-based complementary RRAM in this embodiment includes a bottom conductive electrode; a GeTe thin film dielectric layer disposed on the upper surface of the bottom conductive electrode; and a top conductive electrode disposed on the upper surface of the GeTe thin film dielectric layer.

[0043] The bottom conductive electrode is made of TiN with a thickness of 200 nm and a rectangular shape with a side length of 0.6 μm.

[0044] The dielectric layer of the GeTe thin film has a thickness of 20 nm and a rectangular shape with a side length of 0.6 μm.

[0045] The top conductive electrode is made of Pt, has a thickness of 250 nm, and is rectangular in shape with a side length of 0.6 μm.

[0046] The preparation method of the above-mentioned GeTe-based complementary resistive variable memory in this embodiment includes the following steps: preparing the bottom conductive electrode on the substrate; preparing a GeTe thin film dielectric layer on the upper surface of the...

Embodiment 3

[0051] A GeTe-based complementary RRAM in this embodiment includes a bottom conductive electrode; a GeTe thin film dielectric layer on the upper surface of the bottom conductive electrode; and a top conductive electrode on the upper surface of the GeTe thin film dielectric layer.

[0052] The bottom conductive electrode is made of TiN with a thickness of 200 nm and a rectangular shape with a side length of 0.8 μm.

[0053] The dielectric layer of the GeTe thin film has a thickness of 20 nm and a rectangular shape with a side length of 0.8 μm.

[0054] The top conductive electrode is made of Pt, has a thickness of 250 nm, and is rectangular in shape with a side length of 0.8 μm.

[0055] The preparation method of the above-mentioned GeTe-based complementary resistive memory comprises the following steps:

[0056] The bottom conductive electrode is prepared on the substrate; a GeTe thin film medium layer is prepared on the upper surface of the bottom conductive electrode; a top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com