Steel structure warehouse

A technology for steel structures and warehouses, which is applied to building structures, large-capacity bulk material storage, building types, etc. It can solve the problems of being easily blown over and the goods in the warehouse are easy to be affected by moisture, so as to prevent strong winds from blowing over and avoid goods Moisture, enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further detailed explanation through specific implementation mode below:

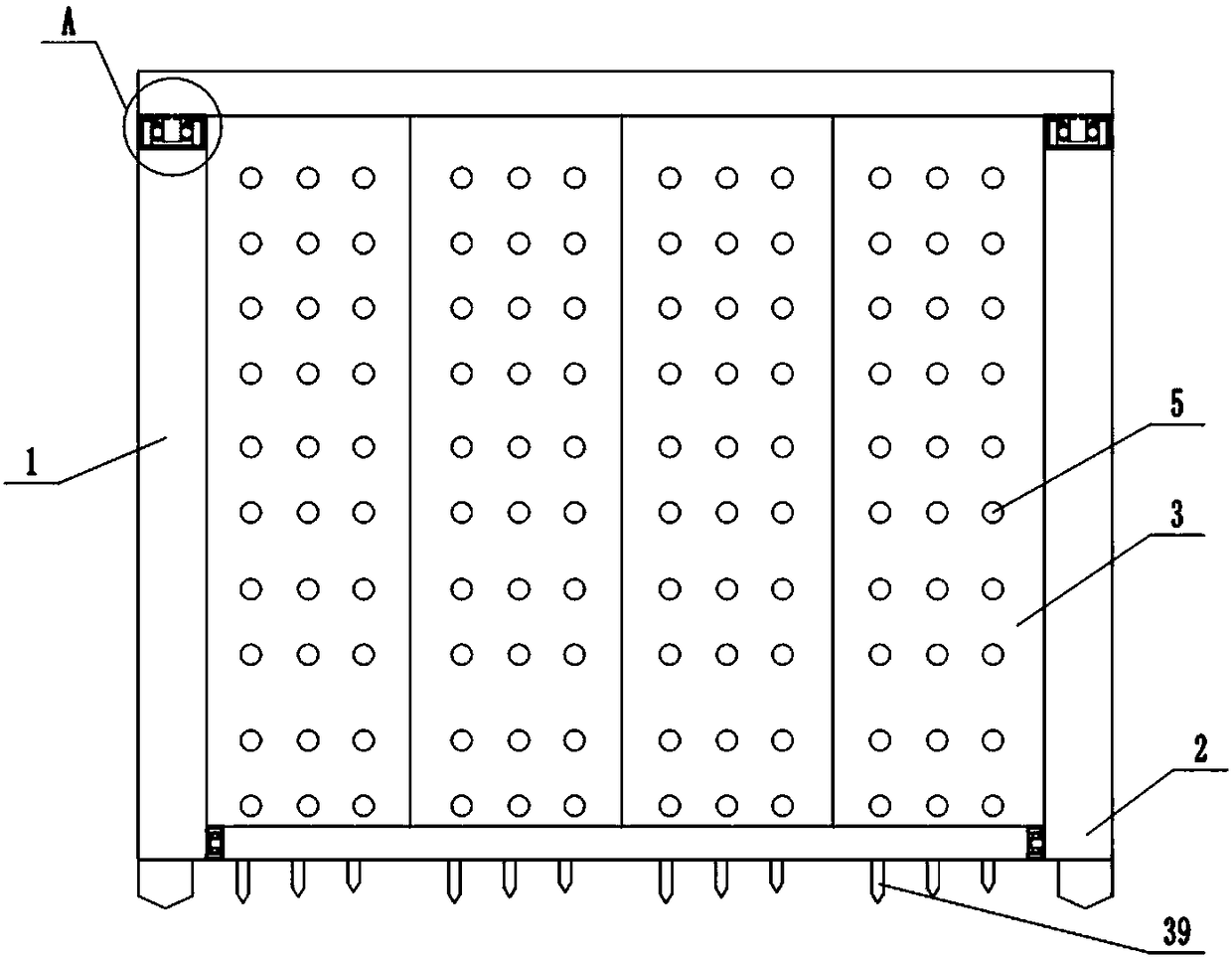

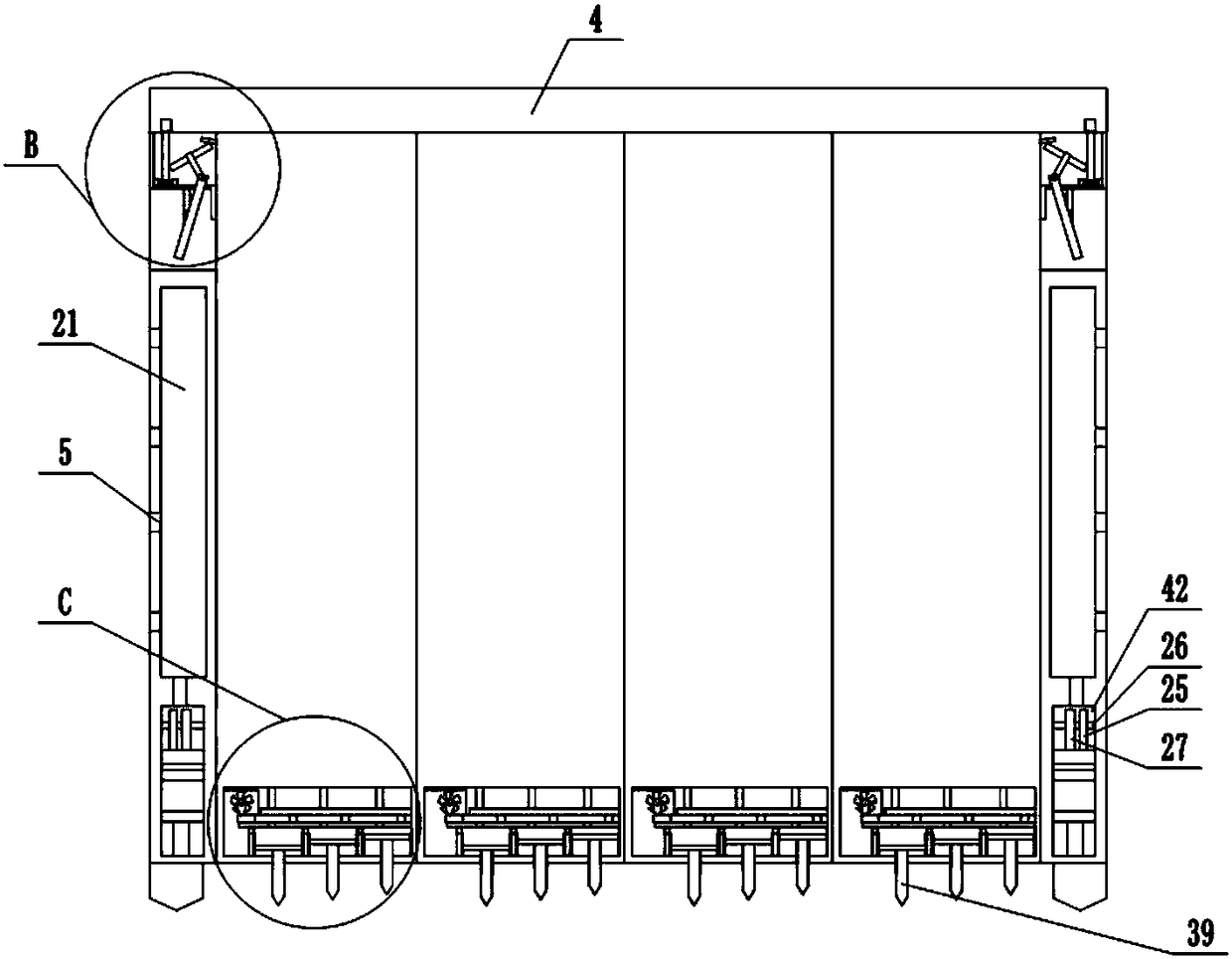

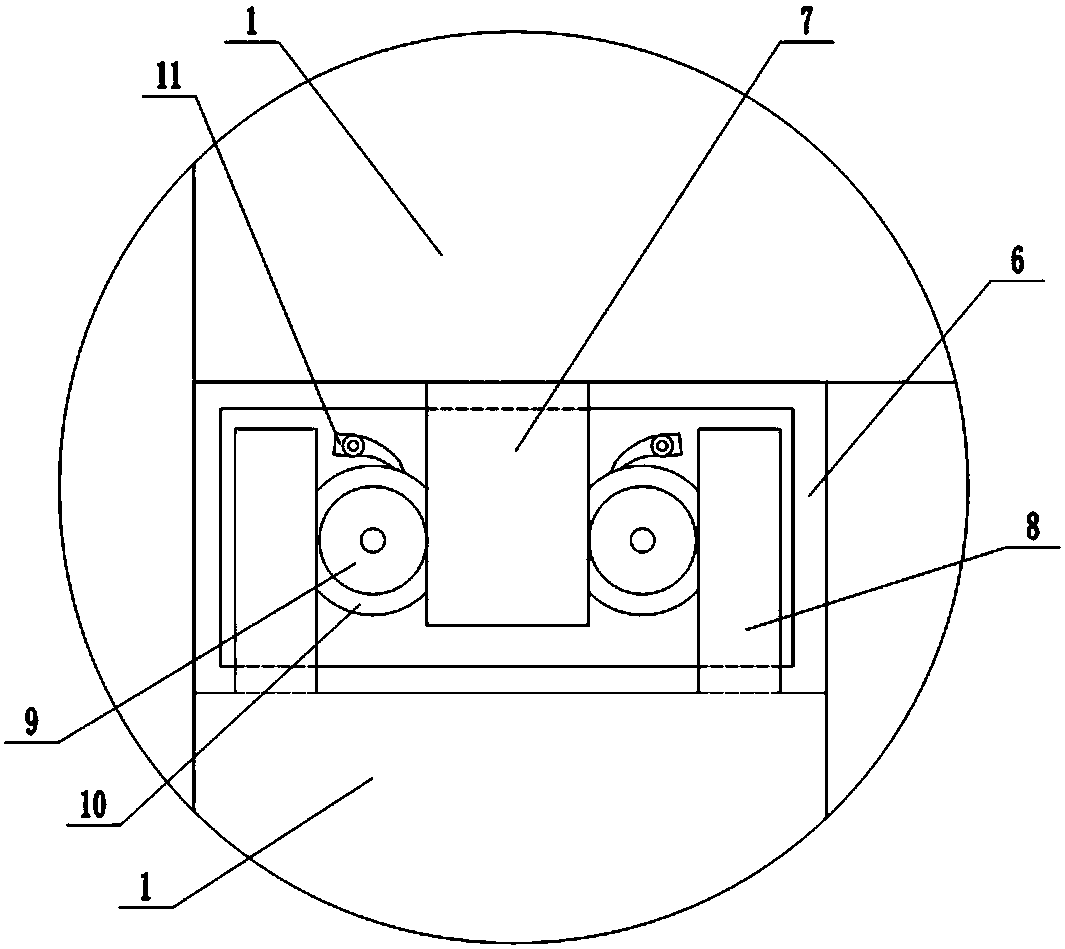

[0031] The reference signs in the drawings of the description include: main beam 1, skeleton 2, side plate 3, top plate 4, air inlet 5, box body 6, first rack 7, second rack 8, gear 9, ratchet 10, Check pawl 11, exhaust port 12, reinforcement cavity 13, strut 14, swing rod 15, baffle plate 16, connecting rod 17, telescopic rod 18, socket 19, insertion rod 20, first chamber 21, second Chamber 22, air pressure chamber 23, communication chamber 24, rotating blade 25, rotating shaft 26, fan teeth 27, interface plate 28, tooth portion 29, docking portion 30, guide rail 31, first flow hole 32, second flow hole 33, Air injection port 34, gas overflow valve 35, heat conduction plate 36, first friction plate 37, second friction plate 38, stake insertion 39, control switch 40, cylinder 41, connecting pipe 42.

[0032] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com