Cathode electrochemical microfiltration membrane coupled reactor suitable for removal of source water pollutants

A microfiltration membrane and electrochemical technology, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as difficult removal of small molecule pollutants, decreased permeability, secondary point source pollution, etc. Achieve the effects of reducing the frequency of membrane cleaning, promoting the generation of oxidant species, and alleviating membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

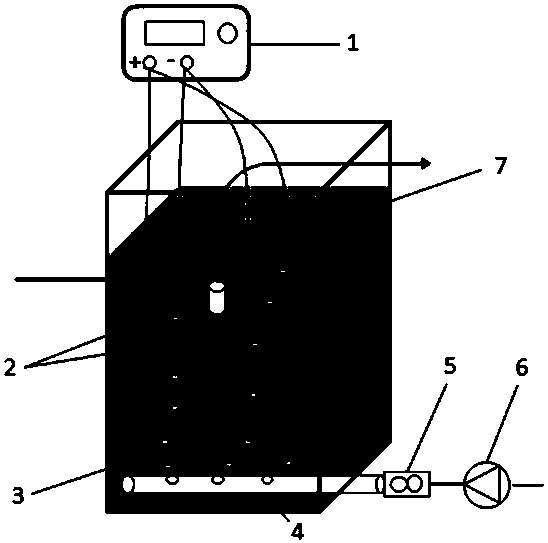

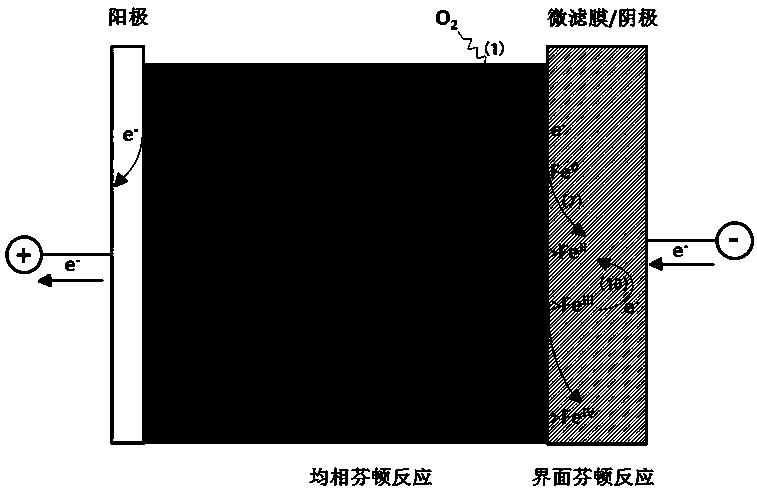

[0021] Embodiment 1: a kind of cathode electrochemical microfiltration membrane coupled reactor, comprising stabilized DC power supply 1, graphite plate anode 2, electrochemical microfiltration membrane cathode 3, gas diffuser 4, gas flow meter 5, air pump 6 and reaction Device housing 7. like figure 1 As shown, in the cathode electrochemical microfiltration membrane coupling reactor, the positive pole and negative pole of the regulated DC power supply 1 are respectively connected to the graphite plate anode 2 and the electrochemical microfiltration membrane cathode 3 through copper wires; the electrochemical microfiltration membrane cathode 3 Placed in the upper part of the reactor, the graphite plate anode 2 is symmetrically arranged on both sides of the cathode 3 of the electrochemical microfiltration membrane, and the distance between the plates is 1cm; a gas diffuser 4 is installed directly below the cathode, and a gas flow meter 5 and an air pump 6 are installed to cont...

Embodiment 2

[0026] The system in Example 1 was used to treat simulated low-concentration p-aminobenzenesulfonic acid (SA) wastewater, the influent SA concentration was 10 μM, the initial pH of the influent was 7, and 50 mM Na 2 SO 4 As an electrolyte, the electrolysis time was 1 h. One set of reactors was set to operate in batch mode, and the applied voltage was 2V; two sets of reactors were set to operate in continuous flow mode, and the electrochemical microfiltration membrane cathode was operated at a flux of 140 L / (m 2 h) Operation (hydraulic retention time is 1 h), the experimental group uses 2 V external voltage, and the control group operates under open circuit conditions. During the reaction time of 1 h, the removal rates of SA in batch experiment group, continuous flow experiment group and continuous flow control group were 67 %, 80 % and 0 %, respectively.

Embodiment 3

[0028] Use the system of Example 1 to treat high-concentration SA wastewater, using influent SA concentration of 150 μM, influent initial pH of 7, and adding 50 mM Na 2 SO 4 As an electrolyte, the electrolysis time was 1 h, and an applied voltage of 2 V was used. Two sets of reactors were set up to operate in continuous flow and batch operation modes respectively. Among them, the cathode of the electrochemical microfiltration membrane in the continuous flow experimental group had a flux of 140 L / (m 2 h) Operation (hydraulic retention time 1 h). Within a reaction time of 1 h, the removal rates of SA in the batch experiment group and the continuous flow experiment group reached 70% and 90%, respectively; under electrochemical action, the main degradation products of SA were formic acid, acetic acid, and oxalic acid, which were easily biodegradable. Degraded small molecule carboxylic acids, the total organic carbon (TOC) of small molecule carboxylic acids in the effluent water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com