Silk extract, whitening and freckle-removing composition containing silk extract and preparation method of composition

A technology for whitening and removing freckles and extracts, which is applied in the field of cosmetics and can solve problems such as irritation, accelerated pigment decomposition, and inability to use for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

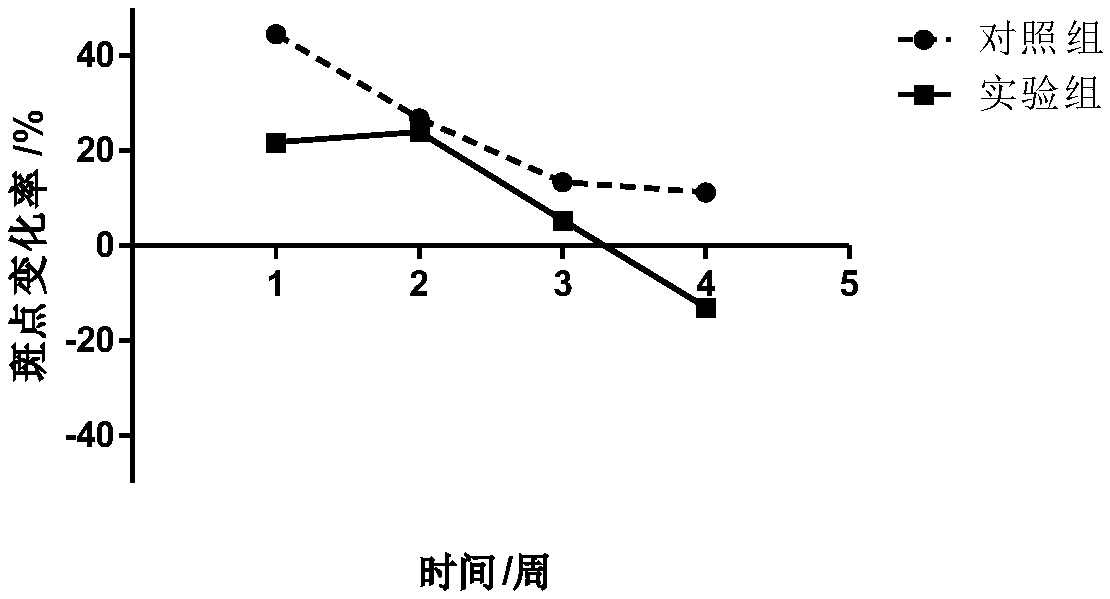

Image

Examples

Embodiment 1

[0047] The present invention carries out following test to silk extraction process:

[0048] No. 1: After the silkworm cocoons are washed and infiltrated, they are put into water at a bath ratio of 1:50, and papain is added to the final concentration of the resulting solution at 3g / L, treated at 60°C for 60 minutes, filtered, and the filtrate is freeze-dried to obtain silk extract.

[0049] No. 2: After the silkworm cocoons are washed and infiltrated, they are put into water at a bath ratio of 1:50, and papain is added to obtain a final concentration of 2g / L, treated at 60°C for 60 minutes, filtered, and the filtrate is freeze-dried to obtain silk extract.

[0050] No. 3: After the silkworm cocoons are washed and infiltrated, they are put into water at a bath ratio of 1:50, treated at 0.1 MPa at 120°C for 120 minutes, filtered, and the filtrate is freeze-dried to obtain silk extract.

[0051] No. 4: After the silkworm cocoons are washed and infiltrated, they are put into water...

Embodiment 2

[0066] A whitening and freckle-removing cream, comprising the following raw materials by weight percentage: silk extract 11%, centella asiatica extract 0.6%, palmitoyl pentapeptide-20 0.2%, yeast lysate extract 2.6%, ceramide -3 0.6%, glycerin 3%, cetearyl olive oil 2.2%, cetyl palmitate 1.8%, jojoba oil 1%, isononyl isononanoate 1%, polydimethyl Siloxanol 1%, Cyclopentasiloxane / Dimethicone Crosspolymer 1%, Isohexadecane 1%, Acrylic Copolymer 0.6%, Egg Phospholipids 0.6%, acrylates / vinyl isodecanoate crosspolymer 0.8%, glycerol polyacrylate 4%, triethanolamine 0.6%, 1,2-pentanediol 1%, the balance is deionized water .

[0067] Wherein, the silk extract is made through the following steps:

[0068] After the silkworm cocoons are washed and infiltrated, they are put into water at a bath ratio of 1:40, treated at 0.1MPa, 120°C for 2 hours, filtered, and the filtrate is freeze-dried to obtain silk extract.

[0069] The preparation method of above-mentioned whitening cream, comp...

Embodiment 3

[0076] A whitening and freckle-removing cream, comprising the following raw materials by weight percentage: 6% of silk extract, 0.2% of Centella asiatica extract, 0.5% of palmitoyl pentapeptide-20, 0.2% of yeast lysate extract, ceramide -3 0.2%, Glycerin 5%, Cetearyl Olivate 1.5%, Cetyl Palmitate 1.5%, Jojoba Oil 3.5%, Isononyl Isononanoate 1%, Polydimethyl Siloxanol 3%, Cyclopentasiloxane / Dimethicone Crosspolymer 2.5%, Isohexadecane 2%, Acrylic Copolymer 1%, Egg Phospholipids 1%, acrylates / vinyl isodecanoate crosspolymer 1%, glycerol polyacrylate 5%, triethanolamine 1.5%, 1,2-pentanediol 3%, the balance is deionized water .

[0077] Wherein, the silk extract is made through the following steps:

[0078] After the silkworm cocoons are washed and infiltrated, they are put into water at a bath ratio of 1:60, treated at 0.15 MPa and 110°C for 3 hours, filtered, and the filtrate is freeze-dried to obtain silk extract.

[0079] The preparation method of the whitening and freckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com