High-bearing-force thin-wall steel tube concrete pile construction method and device and application thereof

A thin-walled steel pipe, bearing capacity technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high risk of steel pipe breaking, no buffer, and inability to ensure anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: A high-bearing-capacity thin-walled steel pipe concrete pile is constructed using a general-purpose internal hammer.

[0065] The top-to-bottom soil layer of the site: about 1m thick miscellaneous fill soil, about 2m thick soft plastic-plastic silty clay, about 5m thick slightly dense, medium dense to dense fine sand, medium sand, Fully weathered mudstone about 2m thick, strongly weathered mudstone about 3m thick, and moderately weathered mudstone below.

[0066] The design adopts thin-walled steel pipe concrete piles with high bearing capacity. The steel pipe is D426*4.2 spiral steel pipe, Q345 material, 12m long, the steel pipe is coated with anti-corrosion coating, the core concrete is C60 self-compacting concrete, and the characteristic value of the compressive bearing capacity is 420 tons.

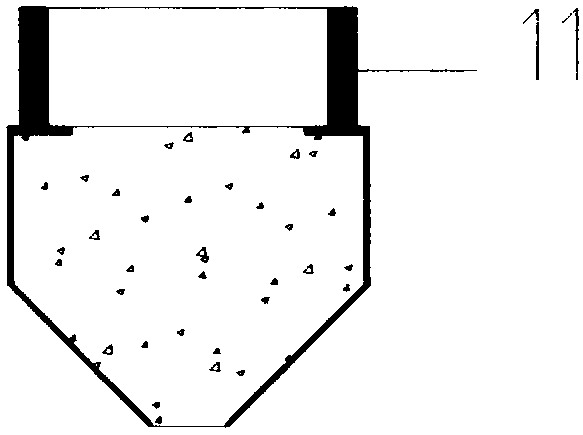

[0067] The big-headed pile point A with outsourcing steel concrete is used, the maximum outer diameter is 508mm, and the overall height is 0.6m. The anti-expansio...

Embodiment 2

[0078] Embodiment 2: A special internal hammer is used to construct a thin-walled steel pipe concrete pile with high bearing capacity.

[0079] Geological conditions and design requirements are the same as in Embodiment 1.

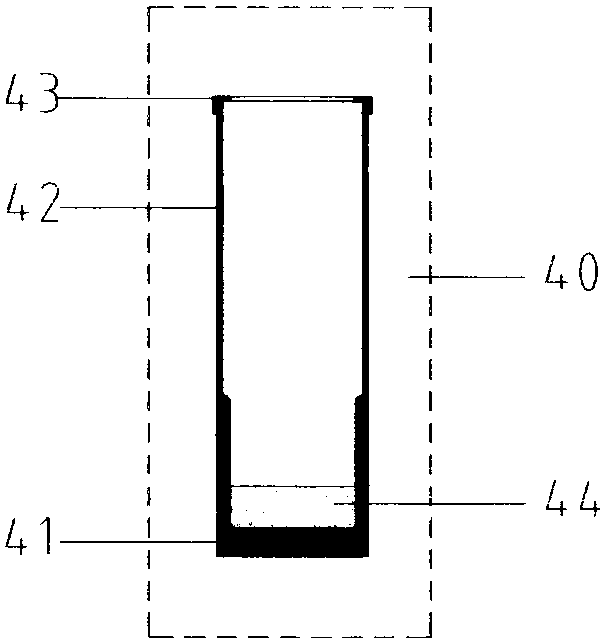

[0080] The steel pipe 42 of the sleeve 40 has a diameter of 390 mm, a thickness of 5 mm, a length of about 3.5 m, an inner diameter of the ring plate of 350 mm, a base plate thickness of 200 mm, a side wall thickness of 35 mm, and a height of 200 mm; the lower section 34 of the hammer body 30 has a diameter of 280 mm and a height of 300 mm; 32 diameters 330mm, high about 4m, upper section 31 diameters 380mm, high about 1.2m, outer flash along 33 diameters 370mm, high 50mm, hammer body 30 gross weight about 4.5 tons, buffer material 44 adopts the machine oil soil of thickness 100~150mm.

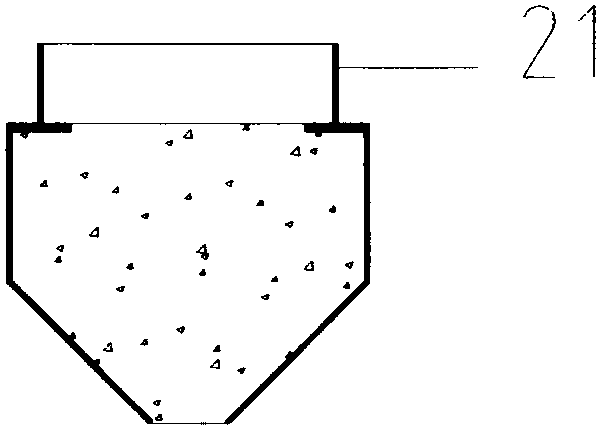

[0081] The pile point adopts the big pile point B, and the connecting steel pipe 21 is a D426*5 spiral steel pipe, made of Q345, and 100mm in height.

Embodiment 3

[0082] Embodiment 3, a special pile machine is used to construct thin-walled steel pipe concrete piles with high bearing capacity.

[0083] The pile driver is a full hydraulic pile driver, the winch 52 is in front, the oil cylinder 53 is behind, the maximum stroke of the piston rod 54 is 1.5m, the hammering frequency corresponding to the stroke 0-1.5m is 15-50 times / min, and the maximum drop of the internal hammer is 3m away.

[0084] Sink the tube throughout. Within the depth range of the pilot hole, it is estimated that the maximum penetration of single click is 100mm.

[0085] Others will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com