Method for smelting TA10 titanium alloy by using electron beam cold hearth

An electron beam cooling hearth furnace and titanium alloy technology, applied in the field of titanium alloy, can solve the problems of poor distribution uniformity of TA10 alloy and excessive volatilization of Ni element, etc., and achieve the effect of fast melting speed, good surface quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

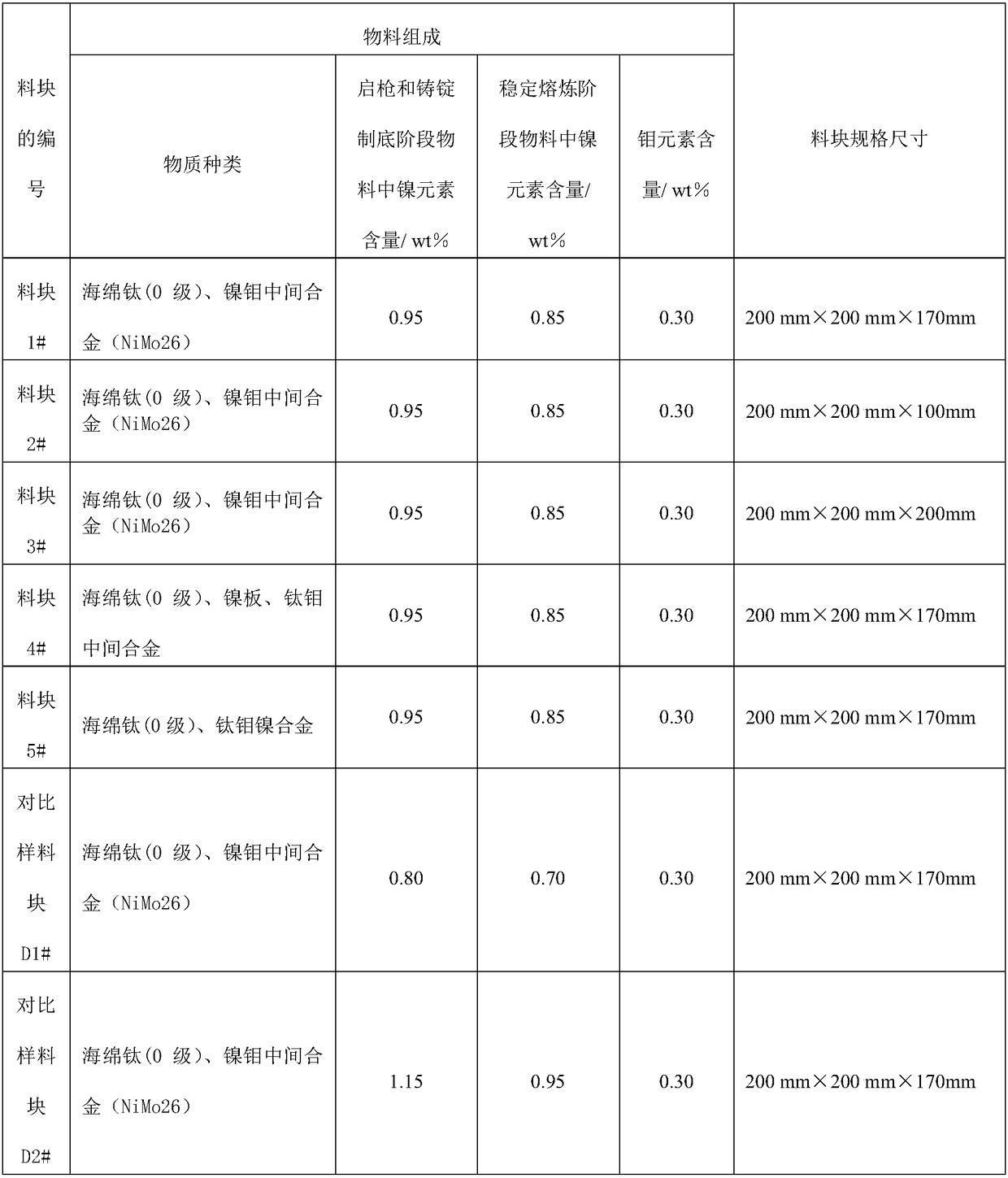

[0069] The pressing of embodiment 1 material piece 1#~5#, comparative sample piece D1#-D2#

[0070] Raw materials containing titanium, nickel and molybdenum are mixed to make the same exact mass of raw material blocks, which are pressed into specific size blocks and dried. Table 1 shows the composition and preparation conditions of the materials of blocks 1# to 5#.

[0071] Table 1

[0072]

[0073] Taking material block 1# as a typical representative to illustrate the preparation method of the material block, the preparation process is as follows:

[0074] a. Sponge titanium (grade 0) and Ni-Mo master alloy with a total weight of 640Kg are all pressed into raw material blocks after mixing. 32 pieces;

[0075] b. The size of the pressed alloy block is: 200mm×200mm×170mm;

[0076] c. Each electronic scale must be calibrated before use, and the measurement accuracy must be tested with a test weight. After the alloy bag is weighed and bagged, it needs to be re-weighed; We...

Embodiment 2

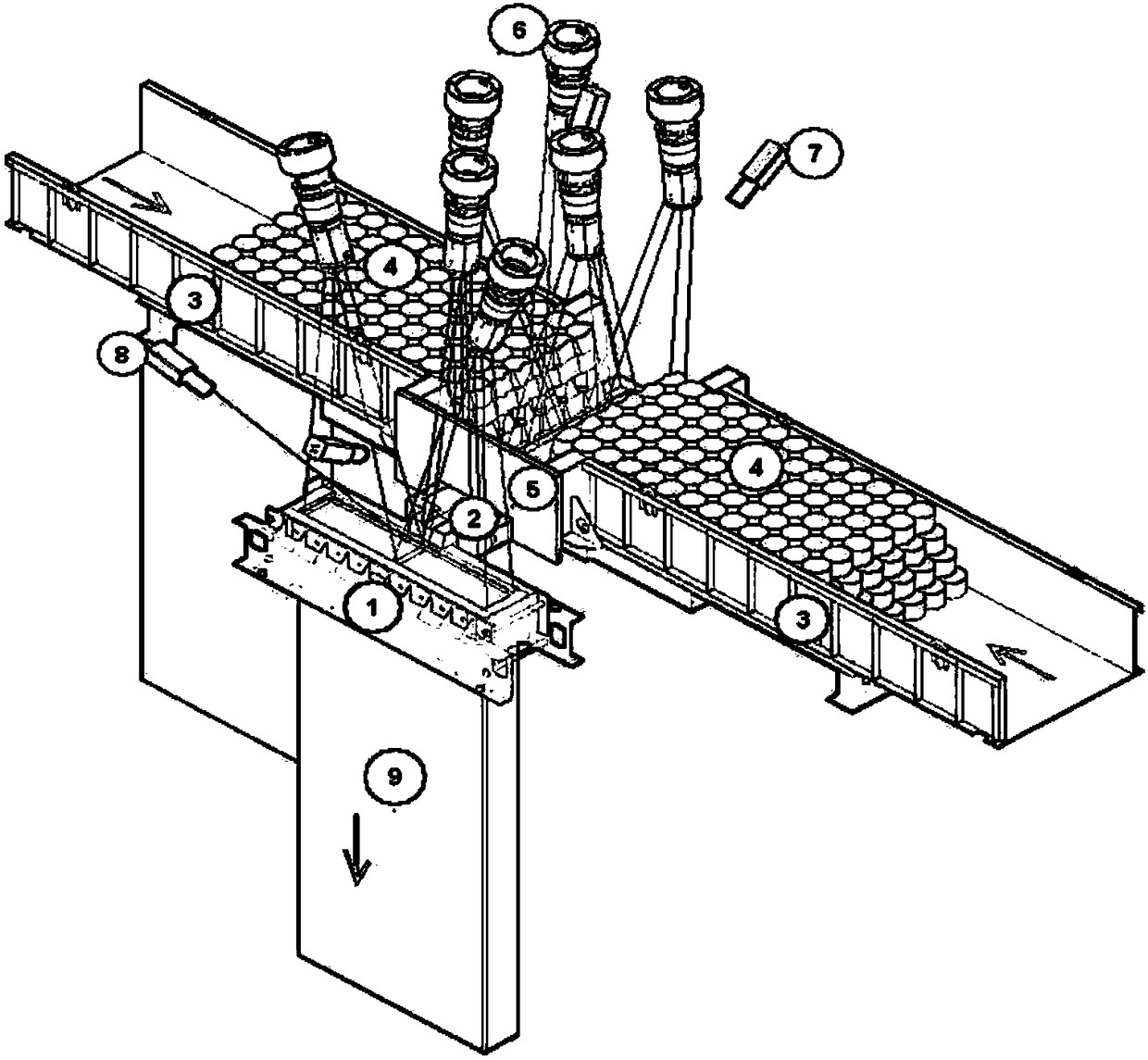

[0078] The feeding method of embodiment 2 material block 1#~5#, comparison sample material block D1#~D2#

[0079] Put the prepared material block 1#~5# and the comparison sample material block D1#~2# into the feeder 3 of the electron beam cooling bed melting furnace as shown in Table 2 to smelt the TA10 titanium alloy. Block 1# is a typical representative to explain the stacking rules of the material block, and the stacking requirements are:

[0080] a. General requirements for stacking

[0081] Stacking rules on the left: 4 blocks in each row, placed in a single layer, a total of 16 alloy blocks are stacked, a total of 4 rows;

[0082] Stacking rules on the right side: 4 blocks in each row, placed in a single layer, a total of 16 alloy blocks are stacked, totaling 4 rows.

[0083] b. The specific stacking position is shown in Table 2: (A represents the feed block in the stage of gun opening and ingot bottom making, and B represents the feed block in the stable smelting stag...

Embodiment 3

[0087] The preparation of embodiment 3 ingot 1#~5#, comparison sample ingot D1#~D2#

[0088] Put the material blocks 1#~5# prepared in Example 1 and the comparative sample blocks D1#~2# in the feeder according to the stacking rules of Example 2, and then smelt them in the electron beam cooling hearth furnace through the following steps to prepare cast iron. The ingots are respectively marked as ingots 1#~5#, and the comparison sample ingots D1#~D2#. The electron beam cooling furnace melting process includes the following stages:

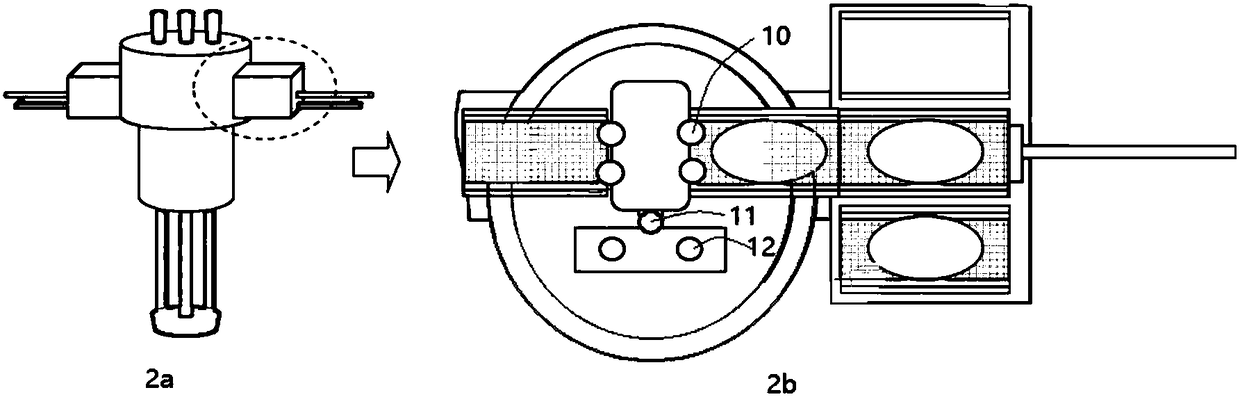

[0089] (1) Start the electron gun stage

[0090] The stage of firing the gun: heat the condensate shell without melting it, and observe the change of vacuum in the furnace. During the oven drying period, the current range of 1~5# guns should be strictly controlled not to exceed 5.0A; at the same time, the current range of 6~7# guns should be started to not exceed 2.0A to preheat the bottom support. After confirming that all electron guns are in nor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com