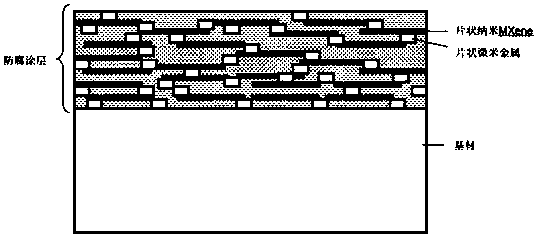

Composite nanometer anti-corrosion coating of shell-imitation structure and preparation method thereof

An anti-corrosion coating, imitation shell technology, applied in anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of environmental pollution of pickling waste, cracking of steel structure surface coatings, threats to workers' health, etc., to achieve adsorption Good effect, low Zn content and long UV aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

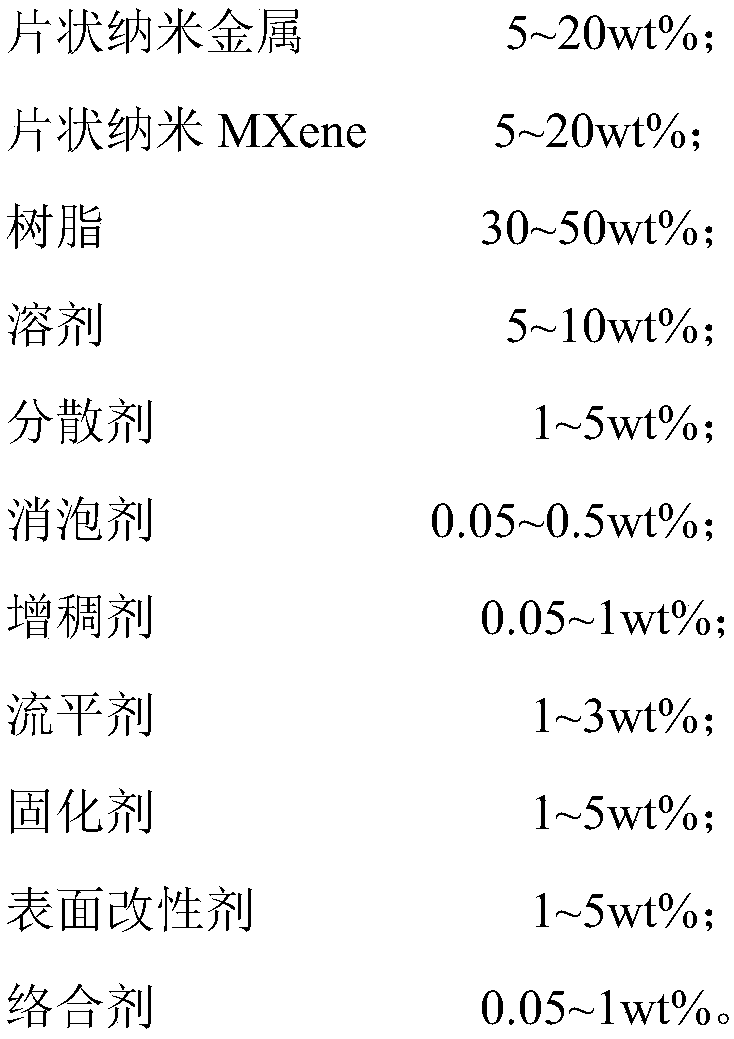

Method used

Image

Examples

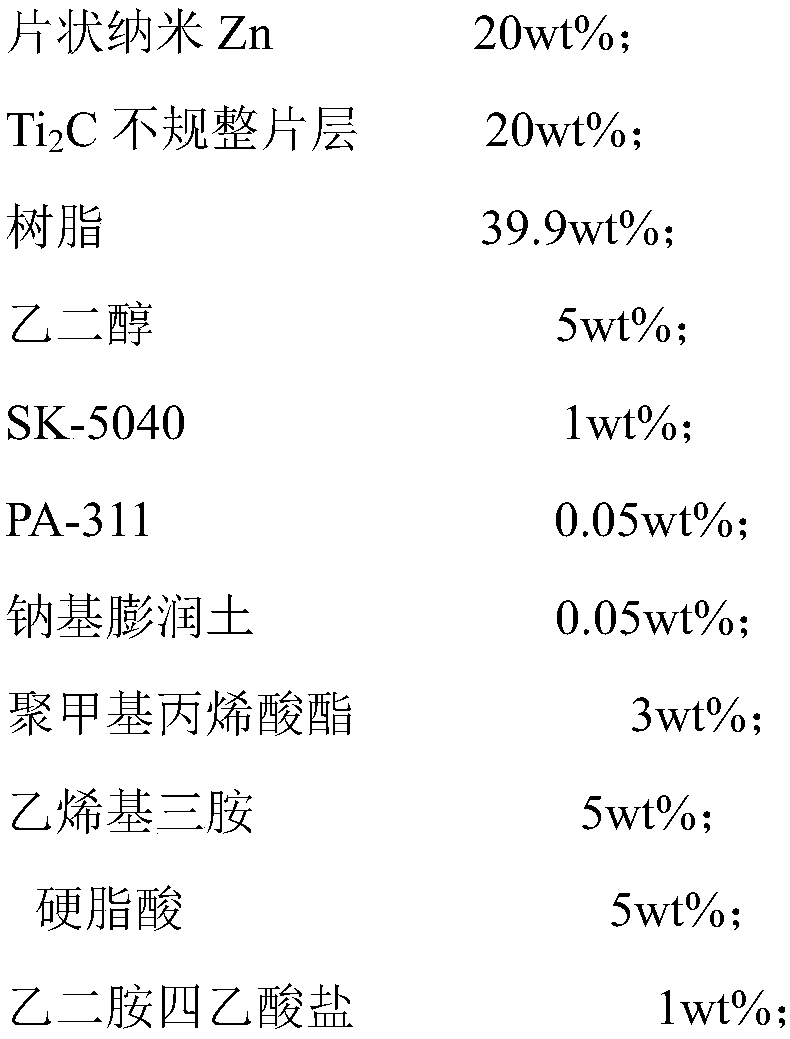

Embodiment 1

[0040] A method for preparing a composite nano anticorrosive coating with a shell-like structure, the steps are as follows:

[0041] (1) First, mix the Ti-containing compound powder, the C-containing compound powder and the Al-containing compound powder at a molar ratio of 2:1:2, and then add them to the planetary ball mill, and pass the Ar gas flow at a rate of 300r / min Grind for 1 hour to prepare the precursor MAX three-dimensional ceramic phase, and then use HF solution to etch MAX to obtain Ti 2 C two-dimensional sheet material;

[0042] (2) Combine the flaky nano-Zn with a thickness of 20μm and a diameter of 50μm and a Ti with a length of 1μm and a thickness of 0.1nm. 2 The irregular lamellae of C were ball-milled in a planetary ball mill at a rate of 430r / min for 2h to obtain a uniform filler slurry, added ethylene glycol and SK-5040, and ultrasonicated for 1h to obtain a uniform MXene-Zn composite dispersion; Ester and butyl acrylate were dissolved in a mass ratio of 1:4 and...

Embodiment 2

[0048] A method for preparing a composite nano anticorrosive coating with a shell-like structure, the steps are as follows:

[0049] (1) First, Ti 2 AlC and TiC were mixed at a molar ratio of 1:1 and then added to the planetary ball mill. The Ar gas flow was introduced, and the grinding was carried out at a rate of 200r / min for 2 hours to prepare the precursor MAX three-dimensional ceramic phase. Then the MAX was etched with HCl solution. Ti 3 C 2 Two-dimensional sheet material;

[0050] (2) The flaky nano Zn with a thickness of 20μm and a sheet diameter of 10μm is combined with Ti with a length of 1nm and a thickness of 10nm. 3 C 2 Irregular flakes were milled in a planetary ball mill with Ar air flow at a rate of 300r / min for 3h to obtain a uniform filler slurry, added acetone and LBCB-1, and ultrasonicated for 2h to obtain a uniform MXene-Zn composite dispersion; after decomposing the dissolved silicone resin Disperse uniformly at a speed of 500rpm, then add MXene-Zn composite d...

Embodiment 3

[0056] A method for preparing a composite nano anticorrosive coating with a shell-like structure, the steps are as follows:

[0057] (1) First, the compound powder containing V, the compound powder containing Si and the compound powder containing C are mixed at a molar ratio of 2:1:1 and then added to the planetary ball mill, and an Ar gas flow is introduced at a rate of 200r / min. Grind for 1h to prepare the precursor MAX three-dimensional ceramic phase, and then use O 2- The compound acid solution etches MAX to obtain V 2 C two-dimensional sheet material;

[0058] (2) Combine a sheet-like nano metal with a thickness of 20 μm and a sheet diameter of 10 μm with a V with a length of 1 μm and a single layer thickness of 0.8 nm. 2 C. Irregular flakes were milled in a planetary ball mill at a rate of 300r / min for 2h to obtain a uniform filler slurry. Water and LBD-1 were added and ultrasonicated for 1h to obtain a uniform MXene-Al composite dispersion; after dissolving the polyvinyl alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com