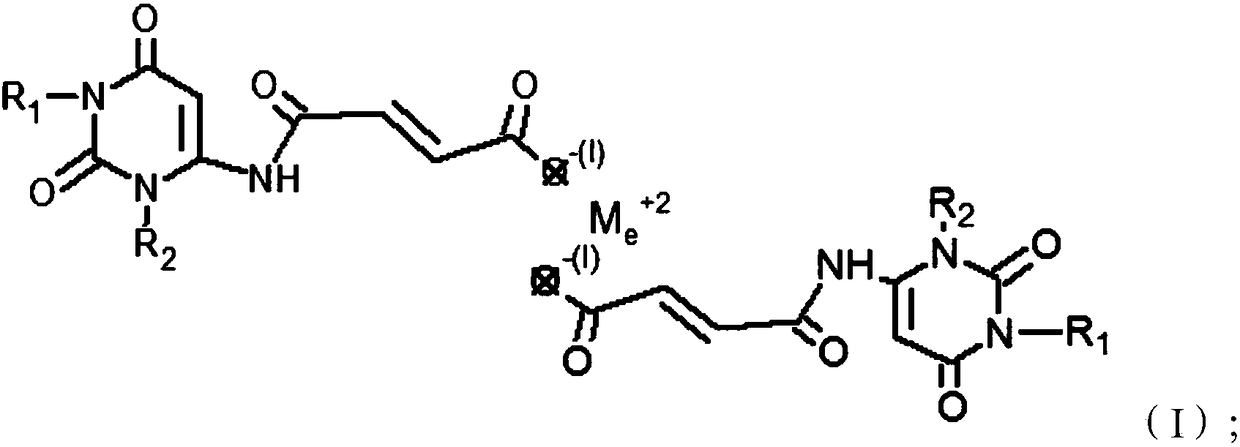

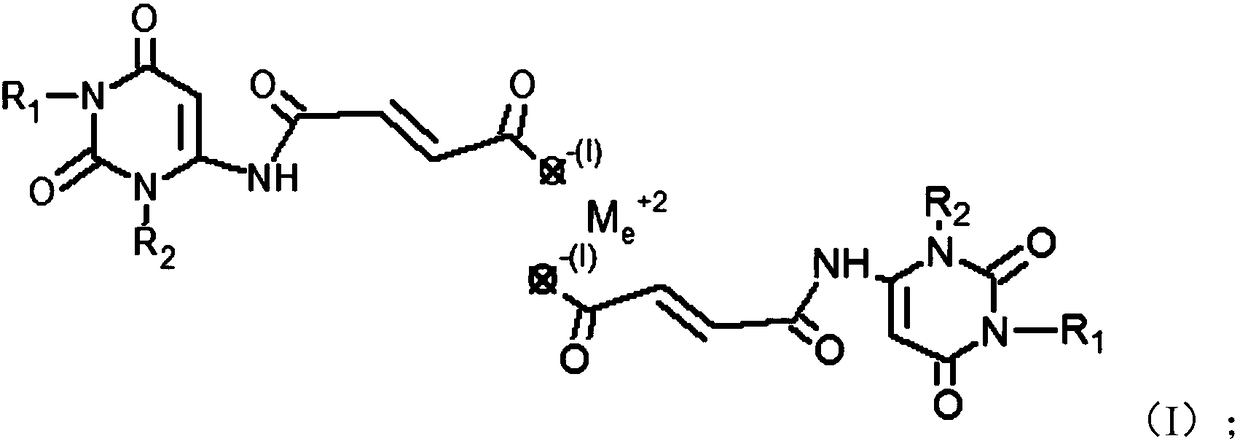

Aminouracil maleamate and preparation method as well as polyvinyl chloride heat stabilizer

A technology of maleamic acid salt and aminouracil, which is applied in the fields of polyvinyl chloride heat stabilizer, aminouracil maleamic acid salt and preparation field, can solve the problem of poor compatibility of PVC, heavy smell of ammonia water, and difficulty in taking into account the initial and long-term Stability and performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

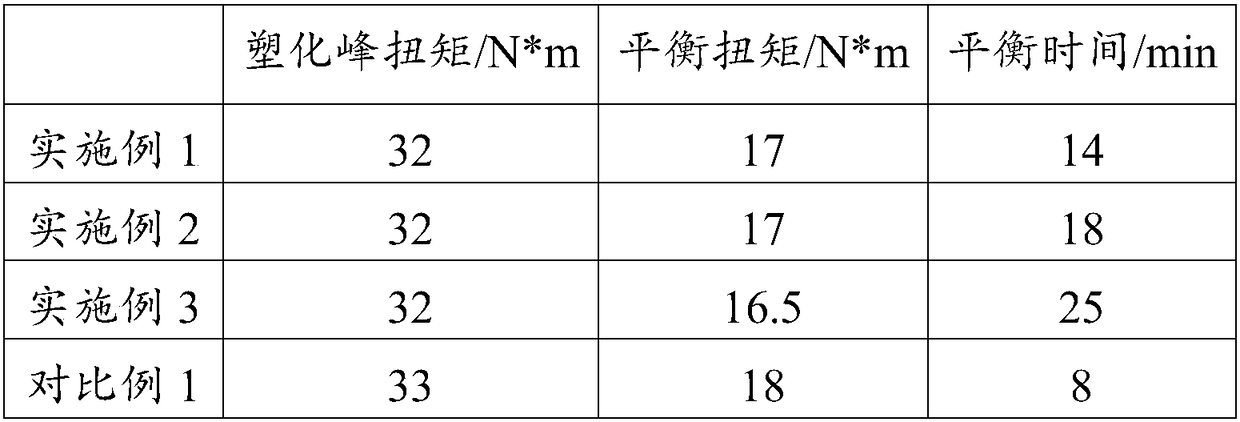

Embodiment 1

[0038] 1. Preparation of zinc aminouracil maleamate

[0039] After pouring maleic anhydride (MAH) into the flask, heat and stir and blow nitrogen, then add semi-uracil compounds, the temperature rises to 70°C, and react for 8 hours; then, add metal compounds and cyclohexane, and heat up to 90°C Reaction 4h, vacuum drying, that is.

[0040] Wherein, the reaction ratio of maleic anhydride and semiuracil compound is 1:1, the molar ratio of metal compound and semicarbazide compound is 1:1, and cyclohexane accounts for 20% of the mass of metal compound;

[0041] The aminouracil compound is selected as 1,3-dialkyl-6-aminouracil; the metal compound is selected as zinc oxide.

[0042] 2. Preparation of polyvinyl chloride (PVC) material

[0043] Formula: 100 parts of PVC, 3 parts of zinc aminouracil maleamate, 2 parts of hydrotalcite, 1 part of stearic acid, 4 parts of calcium carbonate, 4 parts of dioctyl phthalate (DOP), the parts are by weight share;

[0044] Weigh the raw mater...

Embodiment 2

[0046] 1. Preparation of calcium aminouracil maleamate

[0047] After pouring maleic anhydride (MAH) into the flask, heat and stir and pass nitrogen gas, then add aminouracil compounds, the temperature rises to 90°C, and react for 4 hours; then, add metal compounds and toluene, heat up to 110°C, and react for 2.5 hours h, vacuum-dried, that is.

[0048] Wherein, the reaction ratio of maleic anhydride and aminouracil compound is 2:1.5, the molar ratio of metal compound and aminouracil compound is 1:1.5, and toluene accounts for 5% of metal compound quality; Metal compound is selected as calcium oxide .

[0049] 2. Preparation of polyvinyl chloride (PVC) material

[0050] Recipe: 100 parts of PVC, 3 parts of aminouracil calcium maleamate, 2 parts of hydrotalcite, 1 part of stearic acid, 4 parts of calcium carbonate, 4 parts of dioctyl phthalate (DOP), the parts are by weight share;

[0051] Weigh the raw materials according to the formula, and mix them evenly with a stirrer to...

Embodiment 3

[0053] 1. Preparation of tin aminouracil maleamate

[0054] After pouring maleic anhydride (MAH) into the flask, heat and stir and blow nitrogen, then add semi-uracil compounds, the temperature rises to 120°C, and react for 2h; then, add metal compounds and toluene, raise the temperature to 130°C, react for 1h , dried in vacuum, that is.

[0055] Wherein, the reaction ratio of maleic anhydride and aminouracil compound is 1:1.5, the molar ratio of metal compound and aminouracil compound is 1:1.5, and toluene accounts for 10% of the mass of metal compound; the metal compound is selected as tin oxide .

[0056] 2. Preparation of polyvinyl chloride (PVC) material

[0057] Recipe: 100 parts of PVC, 3 parts of uracil aminouracil tin maleamate, 2 parts of epoxidized soybean oil, 1 part of stearic acid, 4 parts of calcium carbonate, 4 parts of dioctyl phthalate (DOP), the number of parts is parts by weight;

[0058] Weigh the raw materials according to the formula, and mix them ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com