A method for separation and purification of durene based on bubble fractional crystallization and distillation

A technology of durene and fractional crystallization, which is applied in the directions of crystallization purification/separation, distillation purification/separation, chemical instruments and methods, etc., which can solve the problems of complex process route, poor production environment and low operability of the preparation method, Achieve the effect of improving efficiency and product purity, improving clearance rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

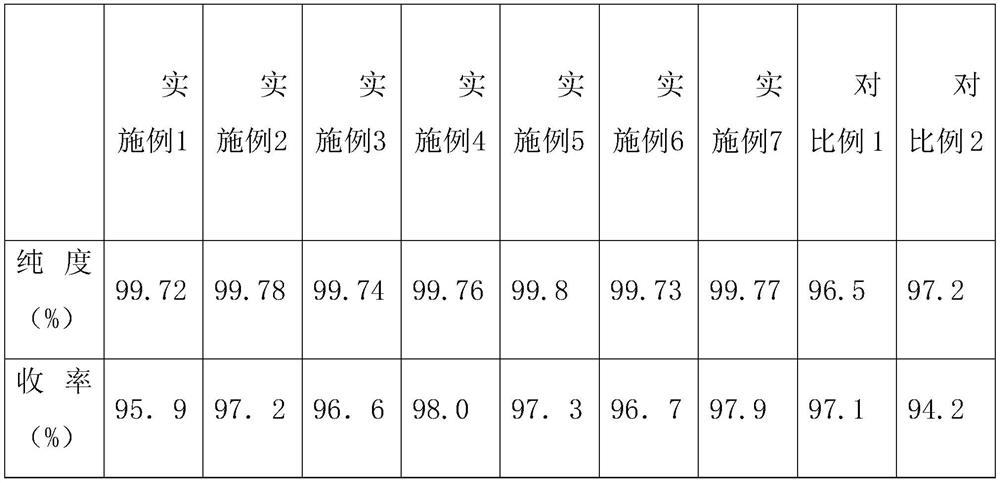

Examples

Embodiment 1

[0025] (1) The material containing 50% durene is added to the crystallizer, and small nitrogen bubbles with a flow rate of 40L / h are introduced from bottom to top, and the temperature is first lowered to -10°C, and then cooled to - at a rate of 0.5°C / min. 25°C, crystallization treatment for 50 minutes, nitrogen gas bubbles with a flow rate of 30L / h from top to bottom, and the crystallized crystals were filtered through a 56°C porous sieve attached to nano-scale metal particles at an angle of 45° for 5 minutes. The aperture of the sieve is 0.5-1mm, and the crude durene is obtained.

[0026] (2) After the crude durene is heated and melted at 130°C, small nitrogen bubbles with a flow rate of 15L / h are introduced from bottom to top, and the temperature is first raised to 190°C at a rate of 5°C / min, and then heated at a rate of 0.1°C / min. The rate of min continues to heat up to 196°C for heat preservation treatment, and the steam is condensed and recovered to obtain separated and p...

Embodiment 2

[0028] (1) The material containing 55% durene is added to the crystallizer, and small nitrogen bubbles with a flow rate of 60L / h are introduced from bottom to top, and the temperature is first lowered to -15°C, and then cooled to - at a rate of 1°C / min. 30°C, crystallization treatment for 90 minutes, nitrogen small bubbles with a flow rate of 50L / h from top to bottom, and the crystallized crystals were filtered through a porous sieve attached to nano-scale metal particles at 60°C for 50 minutes. The aperture of the sieve is 3-5 mm, and the crude durene is obtained.

[0029] (2) After the crude durene was heated and melted at 135°C, small nitrogen bubbles with a flow rate of 45L / h were introduced from bottom to top, and the temperature was first raised to 190°C at a rate of 10°C / min, and then heated at a rate of 0.5°C / min. The rate of min continues to heat up to 198°C for heat preservation treatment, and the steam is condensed and recovered to obtain separated and purified dure...

Embodiment 3

[0031] (1) The material containing 60% durene is added to the crystallizer, and small nitrogen bubbles with a flow rate of 55L / h are introduced from bottom to top, and the temperature is first lowered to -13°C, and then cooled to - at a rate of 0.7°C / min. 24°C, crystallization treatment for 60min, nitrogen gas bubbles with a flow rate of 35L / h from top to bottom, and the precipitated crystals were filtered through a porous sieve attached to nano-scale metal particles at 57°C for 30min, in which the porous The aperture of the sieve is 1-3mm, and the crude product of durene is obtained.

[0032] (2) After the crude durene is heated and melted at 132°C, small nitrogen bubbles with a flow rate of 20L / h are introduced from bottom to top, and the temperature is first raised to 190°C at a rate of 7°C / min, and then heated at a rate of 0.2°C / min. The rate of min continues to heat up to 197°C for heat preservation treatment, and the steam is condensed and recovered to obtain separated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com