a cu 1.8 S-based polycrystalline bulk thermoelectric material and preparation method thereof

A cu1.8s, thermoelectric material technology, applied in thermoelectric device junction lead-out materials, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as reducing thermal conductivity and reducing the electrical conductivity of matrix materials , to achieve the effect of reducing thermal conductivity, maintaining grain morphology, and reducing lattice thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Cu according to the present invention 1.8 The preparation method of S-based polycrystalline bulk thermoelectric material comprises the following steps:

[0025] 1) Preparation of Cu using mechanical alloying method 1.8 For S powder, first weigh Cu and S elemental powder respectively according to the stoichiometric ratio. Under a protective atmosphere, perform ball milling to prepare Cu 1.8 S powder, then add formula ratio X 2 Y 3 Powders are mixed;

[0026] 2) Place the mixed powder in a graphite mold to prepare Cu by spark plasma sintering 1.8 S-based polycrystalline bulk thermoelectric materials.

[0027] The purity of the Cu and S elements described in step (1) is >99.5%, and the protective atmosphere is 5% H 2 +95% Ar, the ball-to-material ratio of the ball milling process is 20~50:1, the speed is 300~450rpm, and the ball milling time is 1~6 h.

[0028] The mixing described in step (1) is manual grinding, ball milling or ultrasonic dispersion.

[0029] The s...

Embodiment 1

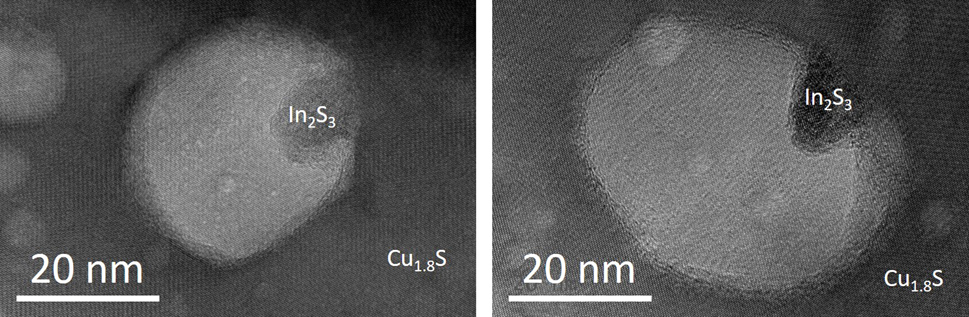

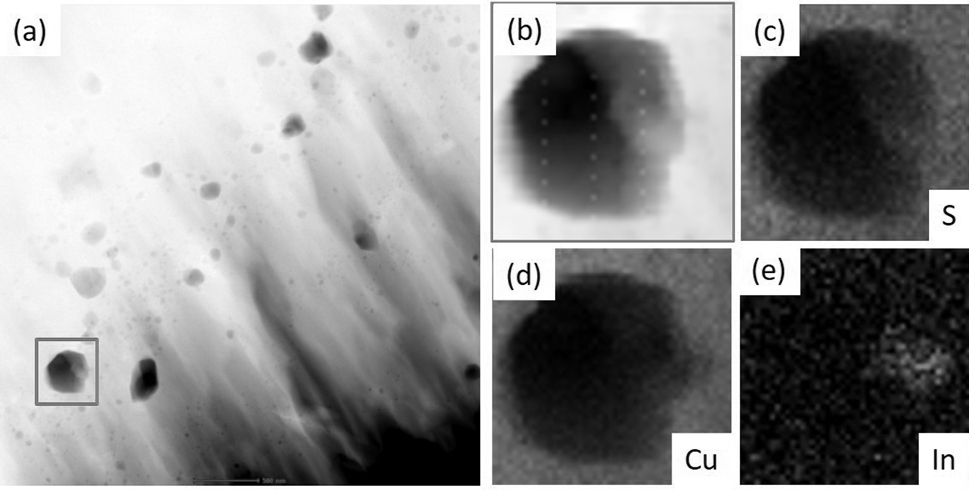

[0031] The present invention Cu 1.8 S+1wt%In 2 S 3 Preparation method and performance characterization of polycrystalline bulk thermoelectric materials.

[0032] 1. Powder preparation

[0033] According to the stoichiometric ratio, 4g of Cu elemental powder and 1.12g of S elemental powder with a purity>99.5% were weighed respectively; 2 Under the protection of +95% Ar atmosphere, the Cu 1.8 S powder. Weigh the In prepared by solid phase sintering method 2 S 3 Powder 0.0512g, and with Cu 1.8 The S powders were mixed and ground for 30 minutes by hand to obtain a mixed powder.

[0034] 2. Preparation of bulk materials

[0035] Pour the powder prepared in step 1 into a graphite mold with a diameter of 15mm, and sinter at 450°C for 5min under a pressure of 50MPa.

[0036] 3. Characterization of thermoelectric properties

[0037] The block obtained by sintering in step 2 was cut into strips of 10×3×3 mm for electrical performance testing, and the rest was ground to φ6×2 m...

Embodiment 2

[0039] The present invention Cu 1.8 S+2wt% In 2 S 3 Preparation method and performance characterization of polycrystalline bulk thermoelectric materials.

[0040] 1. Powder preparation

[0041] According to the stoichiometric ratio, 4g of Cu elemental powder and 1.12g of S elemental powder with a purity>99.5% were weighed respectively; 2 Under the protection of +95% Ar atmosphere, the Cu 1.8 S powder. Weigh the In prepared by solid phase sintering method 2 S 3 Powder 0.1024g, and with Cu 1.8 The S powders were mixed and ground for 30 minutes by hand to obtain a mixed powder.

[0042] 2. Preparation of bulk materials

[0043] Pour the powder prepared in step 1 into a graphite mold with a diameter of 15mm, and sinter at 450°C for 5min under a pressure of 50MPa.

[0044] 3. Characterization of thermoelectric properties

[0045] The block obtained by sintering in step 2 was cut into strips of 10×3×3 mm for electrical performance testing, and the rest was ground to φ6×3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com