A kind of method of recycling aluminum and aluminum slag to produce alumina

A technology of aluminum ash slag and alumina, which is applied in the field of recycled aluminum ash slag to produce alumina, can solve the problems of ineffective acid leaching treatment, long acid leaching time, and increased dosage, so as to reduce time, The effect of shortening the time and reducing the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

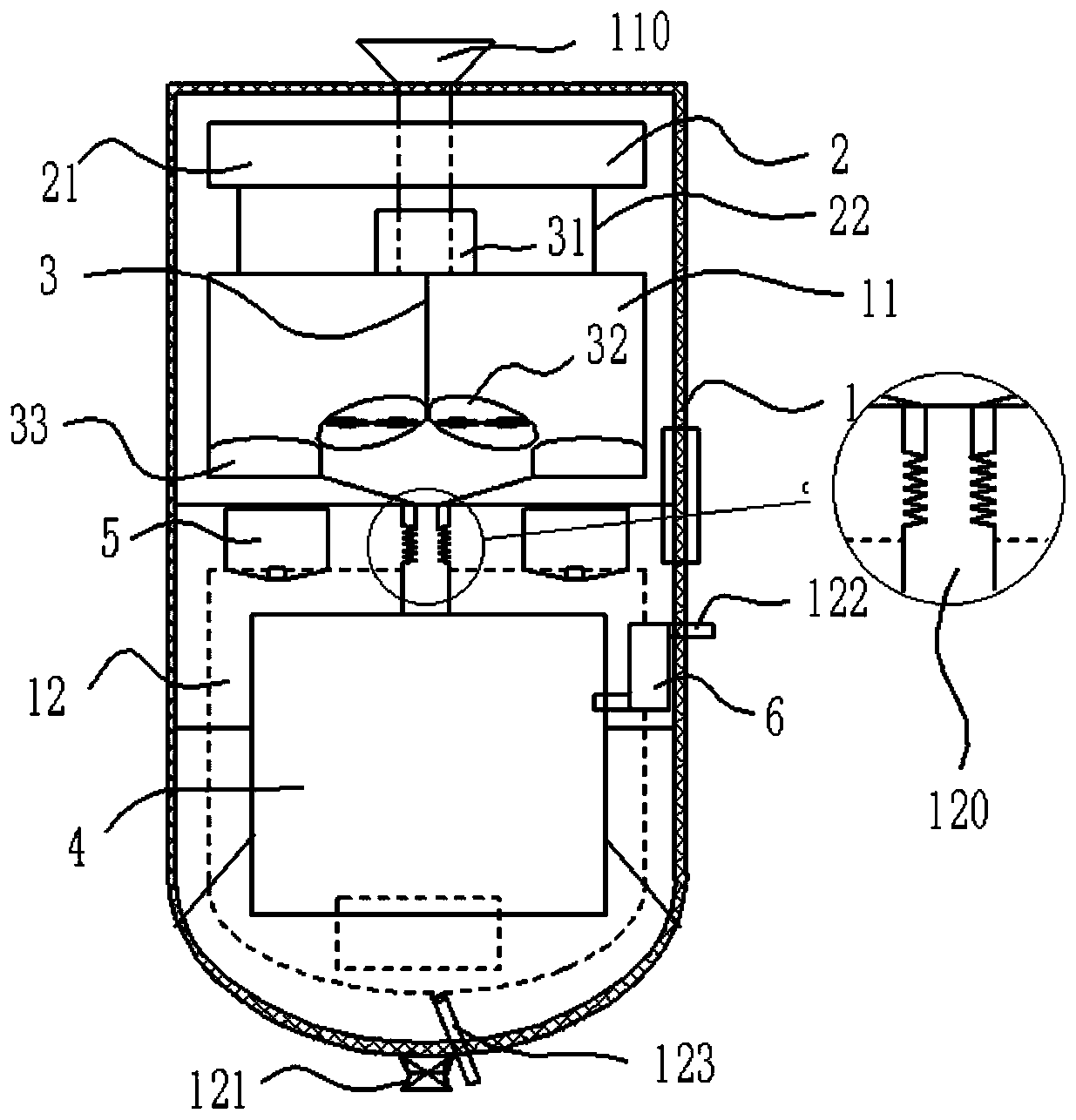

Image

Examples

Embodiment 1

[0035] A method for resourceful production of alumina from recycled aluminum ash slag, mainly comprising the following steps:

[0036] S1: Grinding and cleaning aluminum ash

[0037] Put the rough-filtered aluminum ash into a cleaning device for sieving, grind the aluminum ash with a particle size greater than 150 mesh, and then wash with a mixed solution of ionized water and cleaning agent according to the mass ratio of 150:2 to desalinate, Dry to obtain aluminum ash powder with a particle size of less than or equal to 150 mesh; wherein, the washing and drying conditions are: the aluminum ash to be washed and the mixed solution are cleaned according to the volume ratio of 1:2, the washing time is 1.5h, and the washing temperature is 20 ℃, the drying temperature is 50℃, the drying time is 2h, and the sieving condition is less than 150 mesh;

[0038] S2: low temperature alkaline smelting

[0039] Mix finely ground aluminum ash with NaOH and NaNO 3 The mixed smelting agent co...

Embodiment 2

[0049] Different from Example 1, it is a method for resourceful production of alumina from recycled aluminum and aluminum ash, which mainly includes the following steps:

[0050] S1: Grinding and cleaning aluminum ash

[0051] Put the rough-filtered aluminum ash into a cleaning device for sieving, grind the aluminum ash with a particle size greater than 150 mesh, and then wash with a mixed solution of ionized water and cleaning agent according to the mass ratio of 150:2 to desalinate, Dry to obtain aluminum ash powder with a particle size of less than or equal to 150 mesh; wherein, the washing and drying conditions are: the aluminum ash to be washed and the mixed solution are cleaned according to the volume ratio of 1:2, the washing time is 1.5h, and the washing temperature is 20 ℃, drying temperature 60 ℃, drying time 2h, sieving condition is less than 150 mesh;

[0052] S2: low temperature alkaline smelting

[0053] Mix finely ground aluminum ash with NaOH and NaNO 3 The ...

Embodiment 3

[0062] Different from Example 1, it is a method for resourceful production of alumina from recycled aluminum and aluminum ash, which mainly includes the following steps:

[0063] S1: Grinding and cleaning aluminum ash

[0064] Put the rough-filtered aluminum ash into a cleaning device for sieving, grind the aluminum ash with a particle size greater than 150 mesh, and then wash with a mixed solution of ionized water and cleaning agent according to the mass ratio of 150:2 to desalinate, Dry to obtain aluminum ash powder with a particle size of less than or equal to 150 mesh; wherein, the washing and drying conditions are: the aluminum ash to be washed and the mixed solution are cleaned according to the volume ratio of 1:2, the washing time is 1.5h, and the washing temperature is 20 ℃, drying temperature 80 ℃, drying time 2h, sieving condition is less than 150 mesh;

[0065] S2: low temperature alkaline smelting

[0066] Mix finely ground aluminum ash with NaOH and NaNO 3 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com