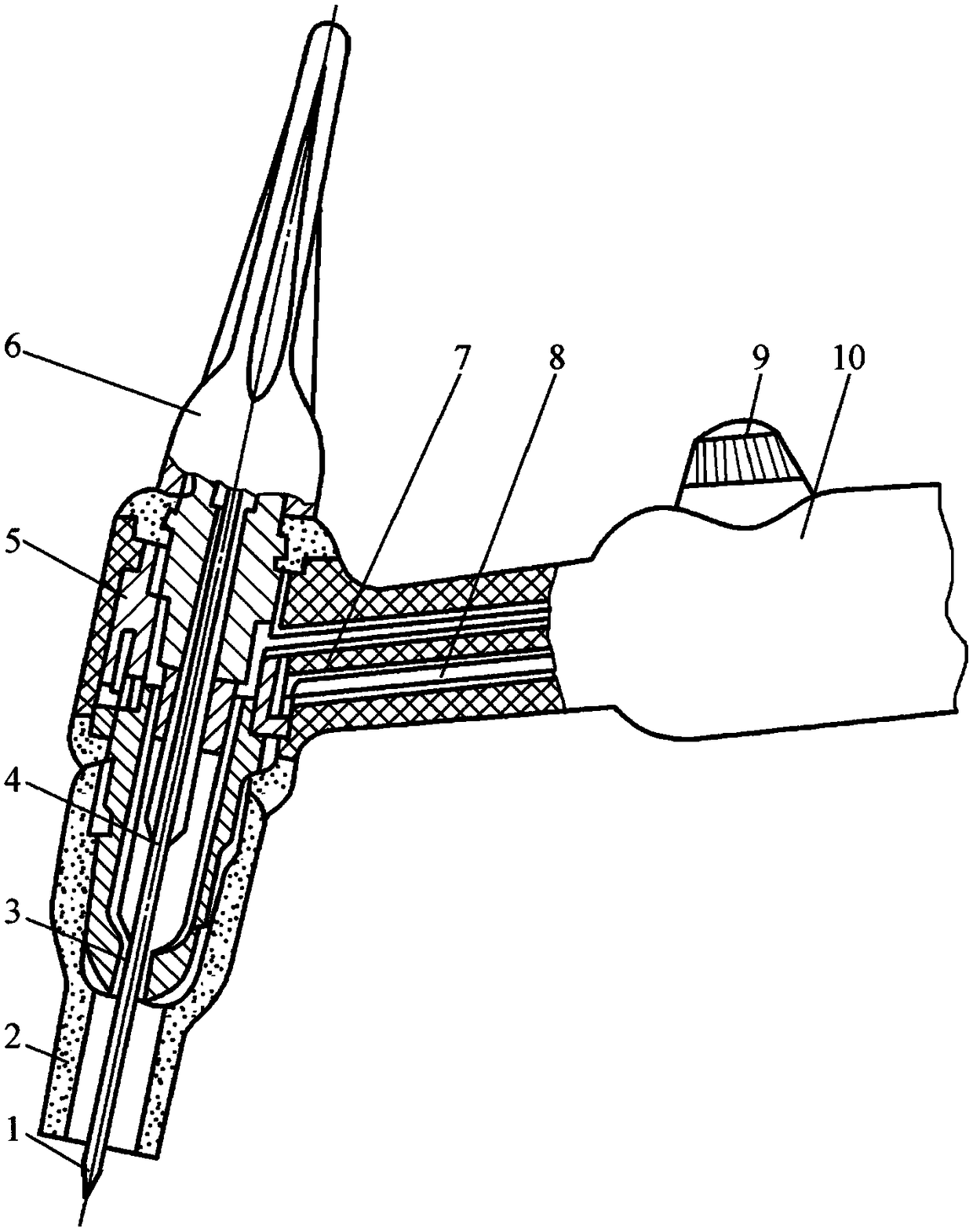

Narrow-gap TIG welding gun

A narrow gap, welding gun technology, applied in the characteristics of welding rods, welding equipment, welding accessories, etc., can solve the problems of increased filler metal content, increased welding material and energy consumption, and decreased welding efficiency, avoiding increased width and improving reliability. , the effect of compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

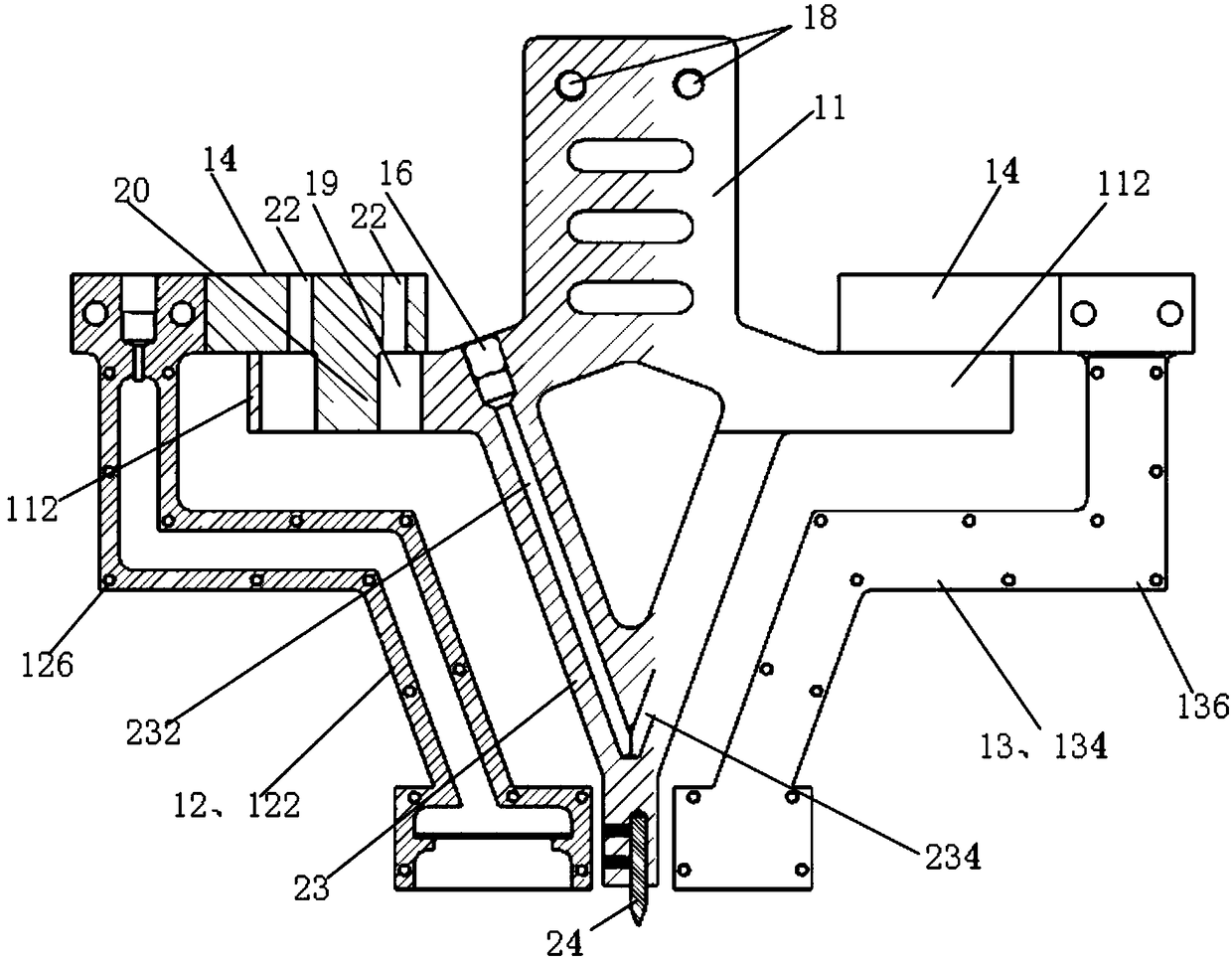

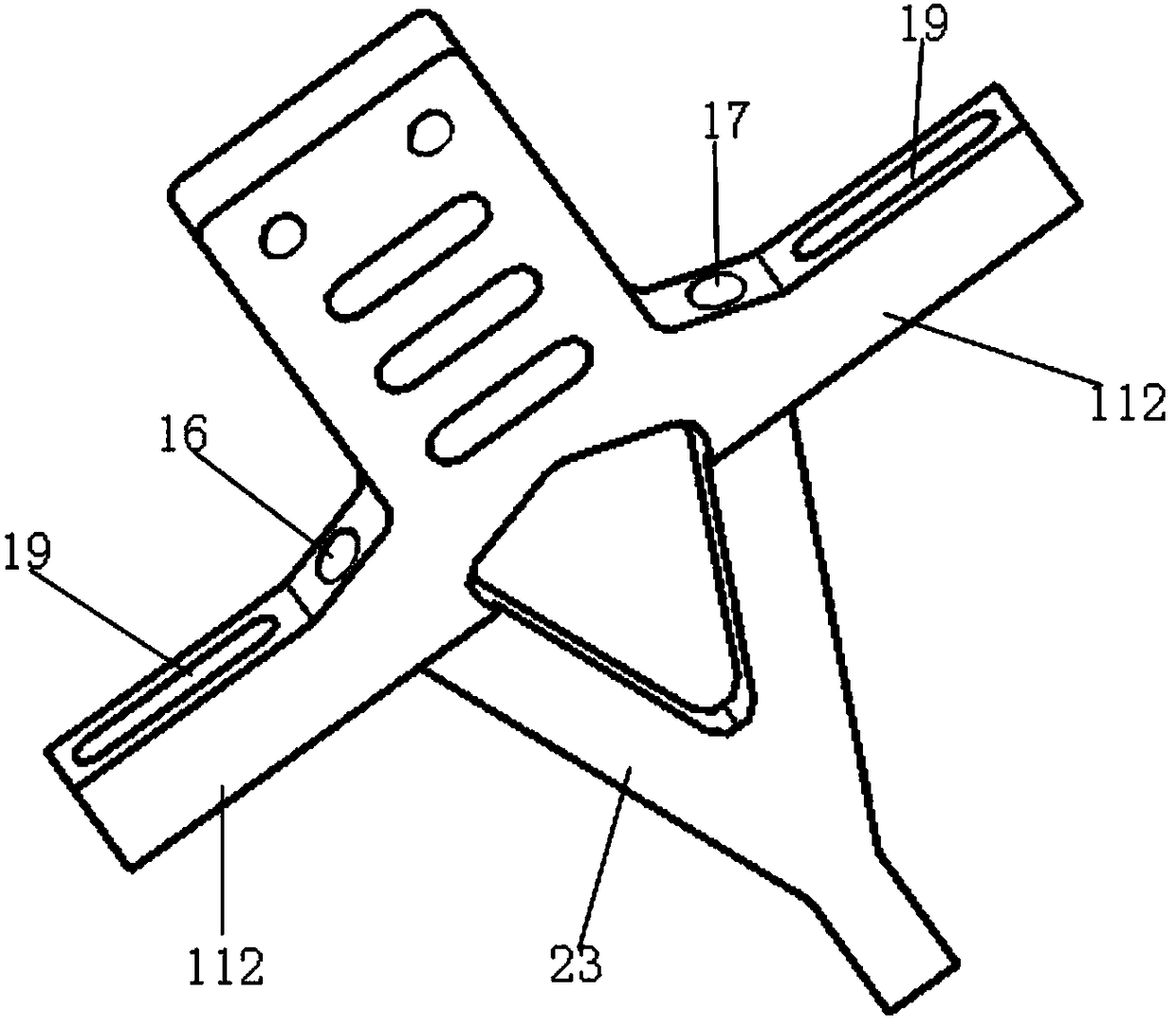

[0033] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0034] Such as Figure 2-5 As shown, a narrow gap TIG welding torch includes a welding torch main body 11 provided with a cooling structure 23, a left gas cover 12 and a right gas cover 13 respectively arranged on both sides of the welding torch main body 11, and isolating the welding torch main body 11 and the left gas cover 12 respectively. 1. Two insulating blocks 14 of the welding torch main body 11 and the right gas shield 13, the welding torch main body 11 is provided with a wire connection port 18, and is conductively connected with a tungsten electrode 24 protruding from the bottom end.

[0035] Specifically, the torch main body 11 has a shoulder and is connected to the cooling structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com