Novel biodegradation nerve conduit and preparation technology thereof

A technology of nerve conduit and lysate, which is applied in the field of neurosurgery, can solve problems such as impermeability, non-degradability, and restriction of nerve growth, achieve good support strength and tensile strength, good biocompatibility, and facilitate adhesion The effect of attached growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a preparation method of a nerve conduit stent, which can be realized by appropriately improving process parameters for reference by those skilled in the art. In particular, it should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they all belong to the protection scope of the present invention. The method and application of the present invention have been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the method and application herein without departing from the content, spirit and scope of the present invention to realize and apply the present invention Invent technology.

[0029] The invention provides a preparation method of a nerve conduit support, comprising:

[0030] A) dissolving the material in a polar solvent to obtain a solution; the material is selected from one or more of polylacti...

Embodiment 1

[0060] Take polylactic acid-glycolic acid copolymer PLGA and polypropylene carbonate PPC total 1200mg (the mass ratio of the two is variable, the ratio can be 4:0, 3:1, 2:2, 1:3, 0:4 , the change in ratio leads to a change in the mechanical strength of the catheter), add 4ml of NMP solution, heat to dissolve, and configure a solution with a mass concentration of 30%, mix it after it is completely dissolved, and settle to remove air bubbles.

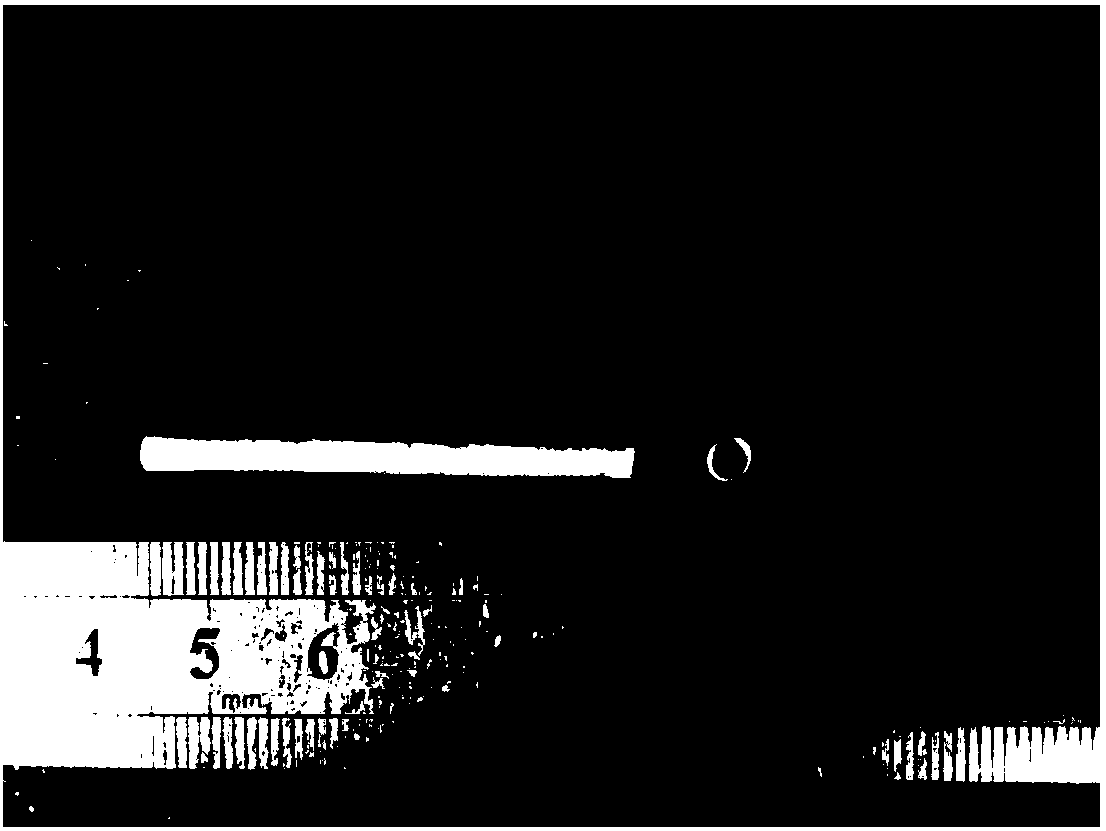

[0061] Spread the fully mixed solution evenly on a dry and anhydrous glass rod-shaped mold, and then place the mold coated with the solution in primary water, and the NMP in the solution will be replaced with water so that the solution on the mold is solidified and completely replaced Finally, a white tubular scaffold is formed, which can be easily peeled off from the glass mold.

[0062] Continue to soak the cured nerve guide bracket in a large amount of water, change the water every 12 hours, and change the water three times until it is...

Embodiment 2

[0065] Take polylactic acid-glycolic acid copolymer PLGA and polypropylene carbonate PPC total 1200mg (the mass ratio of the two is variable, the ratio can be 4:0, 3:1, 2:2, 1:3, 0:4 According to the different mass ratios of the two, they are divided into PLGA-4, PLGA-3, PLGA-2, PLGA-1, and PLGA-0 groups in turn. The change in the ratio will cause the mechanical strength of the catheter to change), add 4ml of NMP solution, heat to dissolve, Prepare a solution with a mass concentration of 30%, mix evenly after completely dissolving, and settle to remove air bubbles.

[0066] Pour the fully mixed solution evenly on a dry and anhydrous glass plate, spread it evenly, and then completely immerse the film-forming solution + plate in water once to completely replace it with water, and the film can be removed after a period of time , continue to immerse in water to completely replace

[0067] Cut the fully displaced membrane into a rectangle and roll it into a tube. Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com