Kelp automatic cutting and rope removing device

A kelp, automatic technology, applied in agricultural machinery and implements, applications, harvesters, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

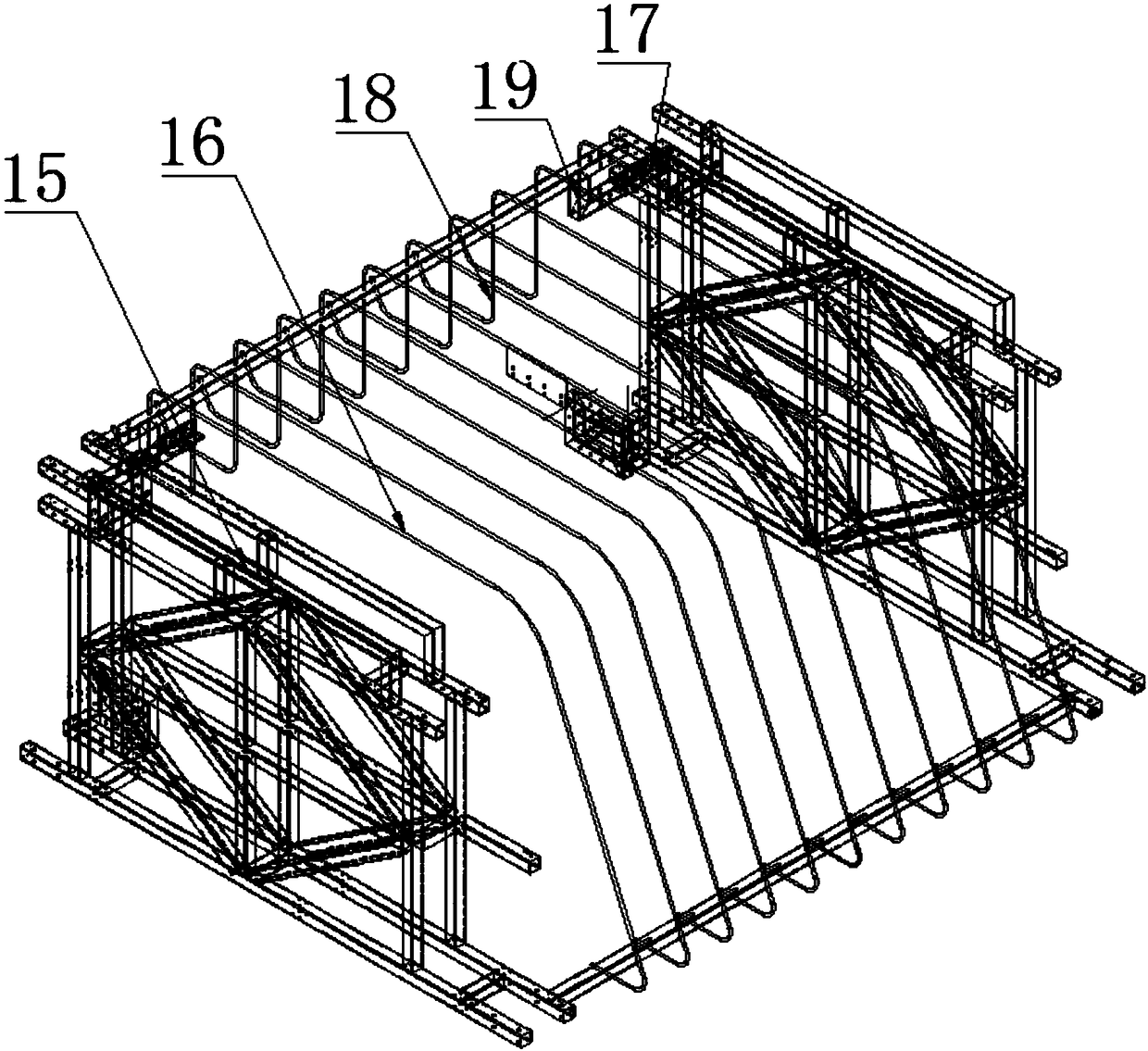

[0034] see Figure 1-10 , a kelp automatic slitting and de-rope device, comprising a frame assembly 5; the frame assembly 5 is provided with a plurality of side-by-side seedling rope guide support rods 16, and the bottom of each seedling rope guide support rod 16 front end is provided with a hook 16a, forming a group of row hooks, on which the seedling ropes for hanging kelp rest on the group of row hooks, and the position between adjacent hooks 16a on the seedling ropes has at most one or several bundles of kelp; the seedling rope guides and supports Bar 16 both sides are provided with claw tightening device, and described claw tightening device can be tensioned to both sides of seedling rope, makes the kelp top to be cut position alignment; Described claw tightening device is fixed on sprocket drive On the mechanism, the transmission directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com