Magnetic pole spaced winding combined stator

A combined, magnetic pole technology, applied in the direction of winding, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problems of small additional torque, large cogging torque, and inability to realize pole-changing speed change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

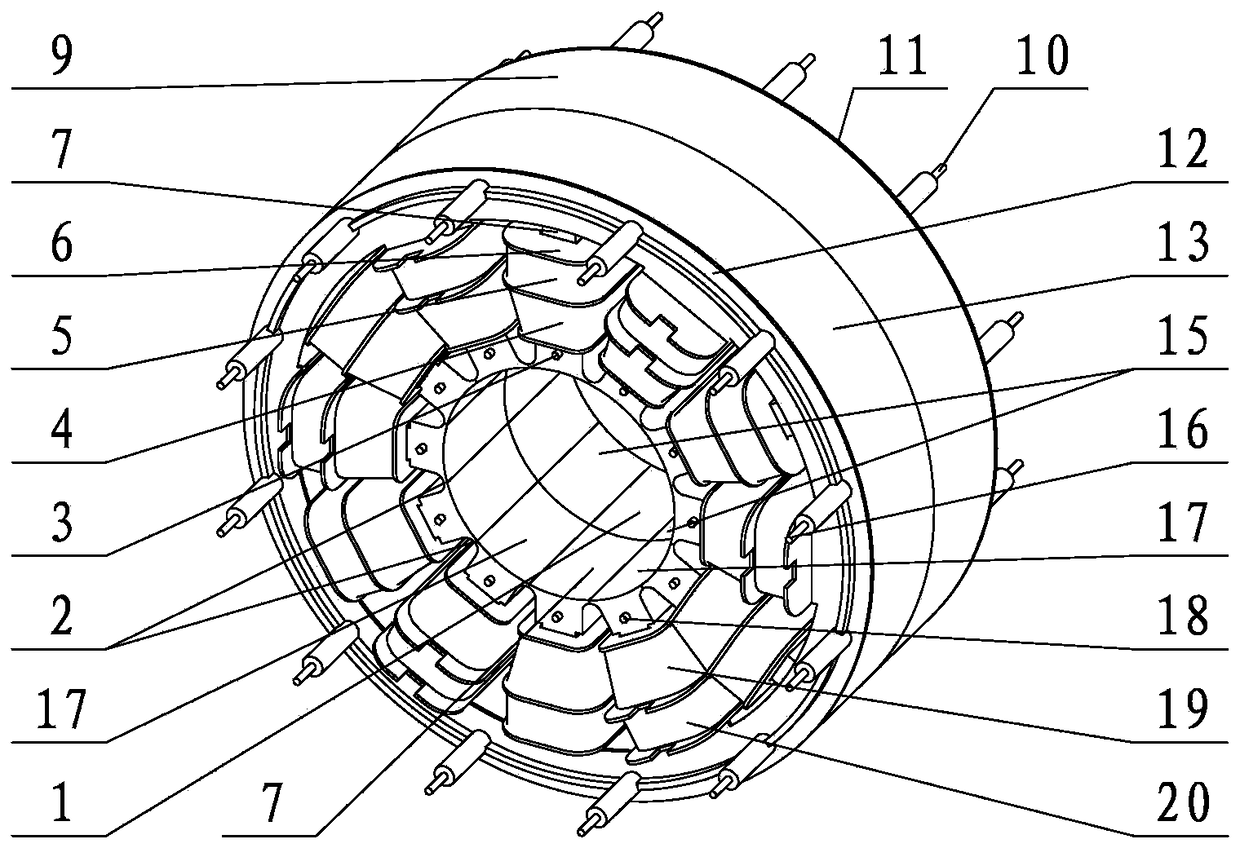

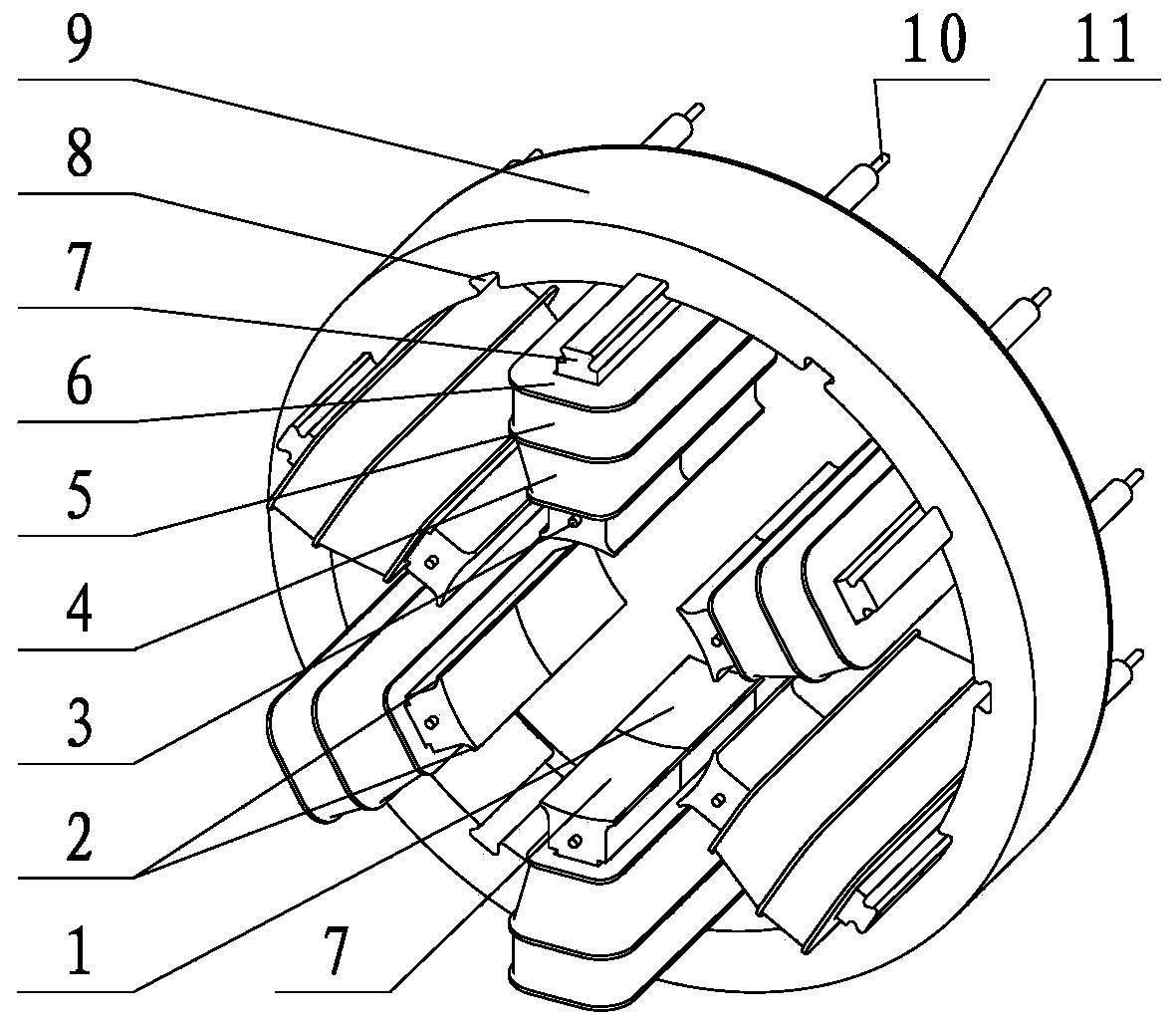

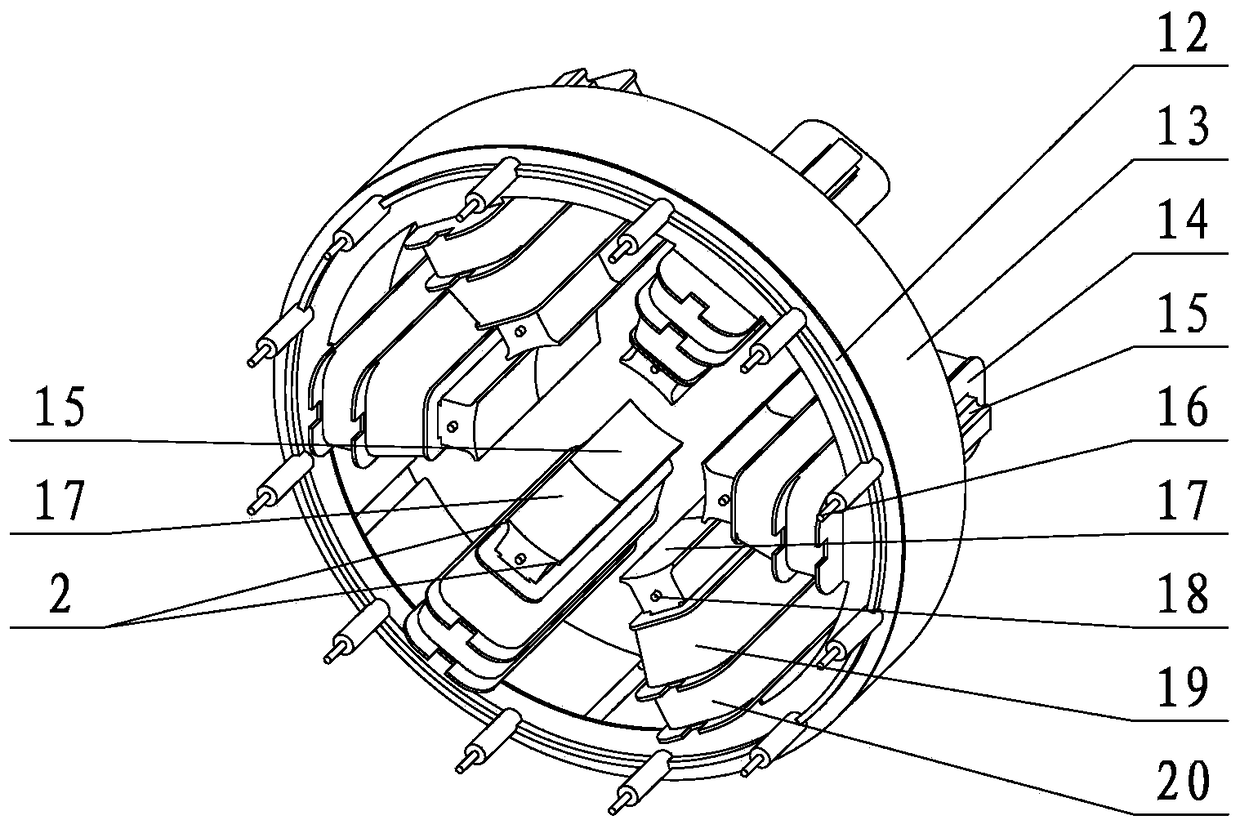

[0061] The present invention is further described below in conjunction with accompanying drawing.

[0062] refer to figure 1 , figure 2 , image 3 , the combined stator includes stator part one and stator part two. Stator part 1 includes stator iron core 9 , magnetic pole insert 7 , positioning pin 3 , ring-shaped coil bobbin 11 , coil bobbin 6 , and welding pin 10 . The annular bobbin 11 includes several positioning bobbins 27, and each positioning bobbin 27 and bobbin 6 respectively have one or several bobbin slots, if each positioning bobbin 27 and bobbin 6 There is a skeleton wire groove respectively, then stator part one also includes coil one, if each positioning coil skeleton one 27 and coil skeleton one 6 have two skeleton wire slots respectively, then stator part one also includes inner coil one 4, outer coil a 5. The second stator component includes a second stator core 13 , a second magnetic pole insert 15 , a second positioning pin 18 , a second annular coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com