Full-automatic high-speed intelligent printing, slotting and die-cutting machine and working method thereof

A fully automatic, slotted die technology, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of unadjustable spacing, discontinuous production, increased manual labor intensity, etc., and achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

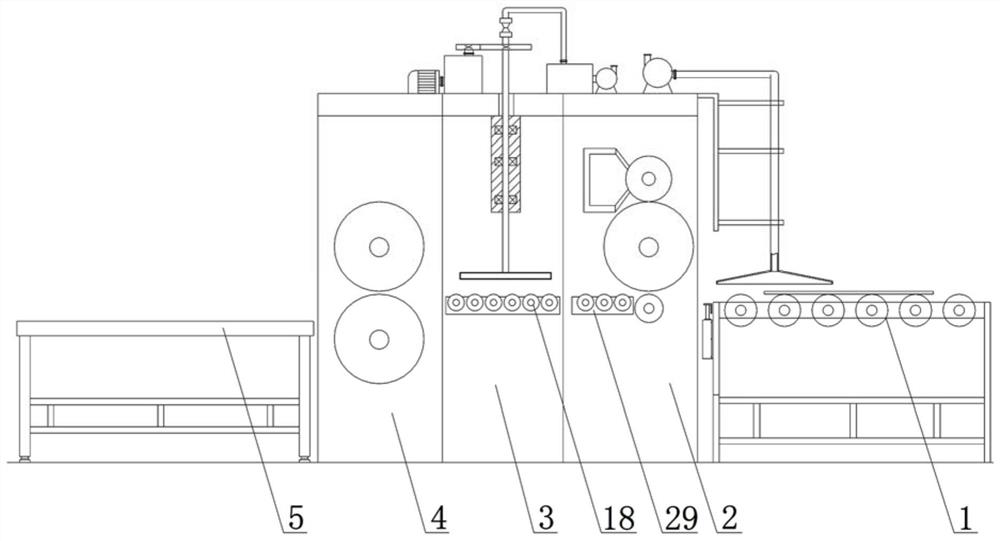

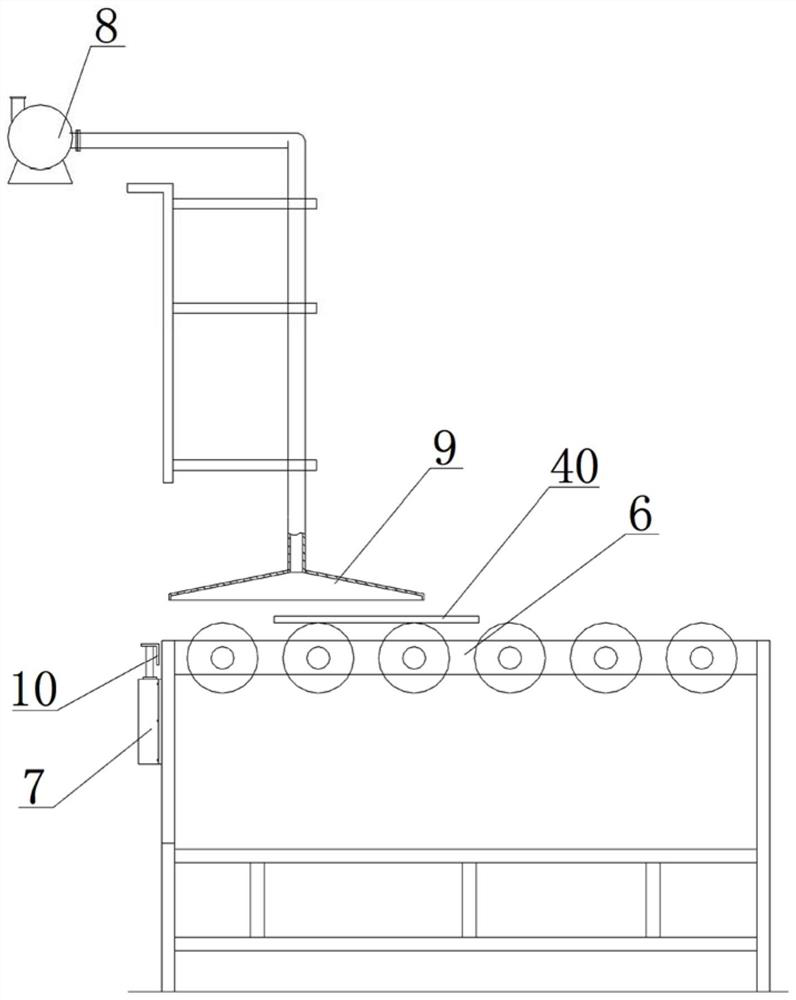

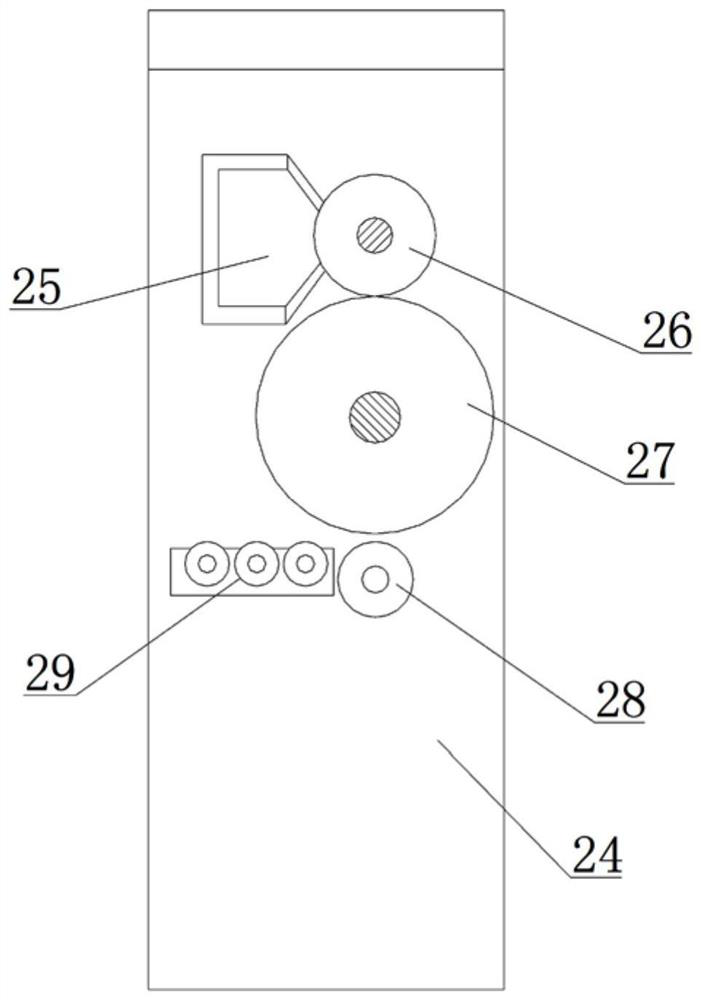

[0037] like Figure 1-9 As shown, the fully automatic high-speed intelligent printing slotting die-cutting machine includes a paper feeding device 1, a printing device 2, a drying device 3, a slotting device 4 and a collecting platform 5 arranged sequentially from right to left. The paper device 1 includes an input roller table device 6, a lifting cylinder 7, a blower 8 and a wind cover 9. The lifting cylinder 7 is fixed at the left end of the frame of the input roller table device 6, and a baffle is fixed on the piston rod of the lifting cylinder 7. 10, the air cover 9 is arranged directly above the input roller table device 6, and the air outlet of the blower 8 is connected to the top port of the air cover 9 through a pipeline; the drying device 3 includes a second frame 11, a power unit, an air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com