A kind of opposite-side cascade semiconductor chip device and cascade method

A semiconductor and chip-level technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., to achieve high surface activity and surface energy, save packaging space, and prevent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

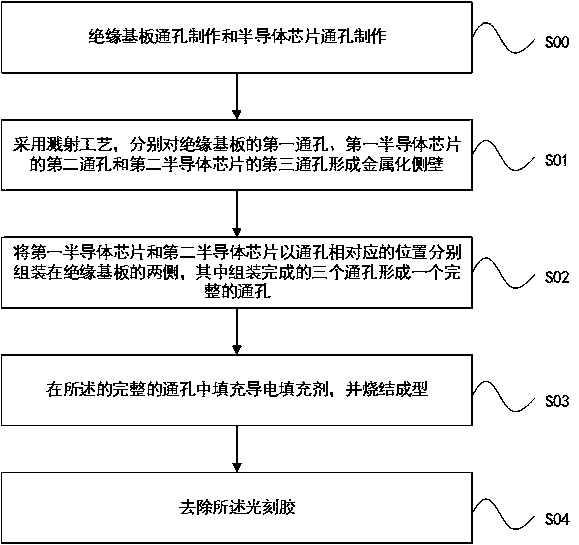

[0043] Further describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

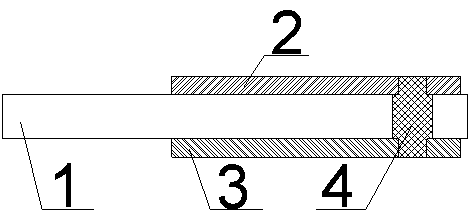

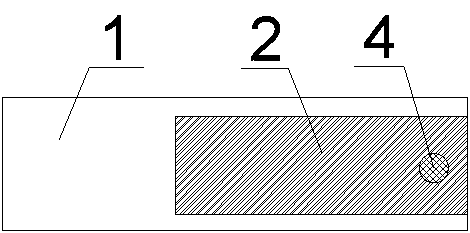

[0044] Such as figure 1 and figure 2 Shown, a kind of opposite-side cascaded semiconductor chip device comprises:

[0045] An insulating substrate 1, the insulating substrate 1 has a first through hole 5;

[0046] The first semiconductor chip 2 and the second semiconductor chip 3 assembled on both sides of the insulating substrate 1 respectively; wherein, the first semiconductor chip 2 has a second through hole 7, and the second semiconductor chip 3 has a third through hole 8, after the assembly is completed After the first through hole 5, the second through hole 7 and the third through hole 8 form a complete through hole 9; the first through hole 5, the second through hole 7 and the third through hole 8 all have metallization side wall;

[0047] The conductive filler 4 filled to the complete through hole 9 and sintered into shape.

[0048] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com