Environment-friendly compound enhanced type cement and preparation method thereof

A composite reinforcement, cement technology, applied in the field of building materials, can solve the problems of insignificant improvement of cement performance, collapse of pore structure, poor structural stability, etc., to improve chemical corrosion resistance and thermal stability, hardened structure stability, and structural integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

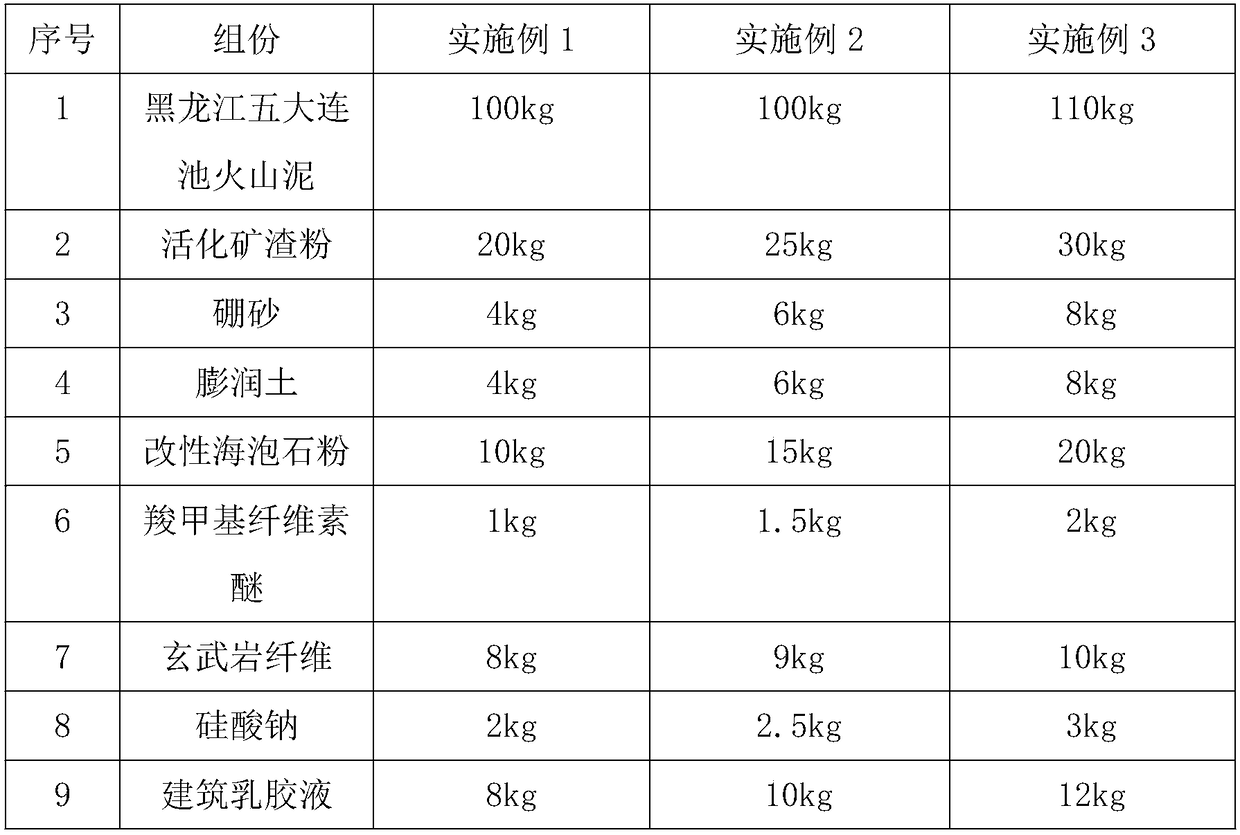

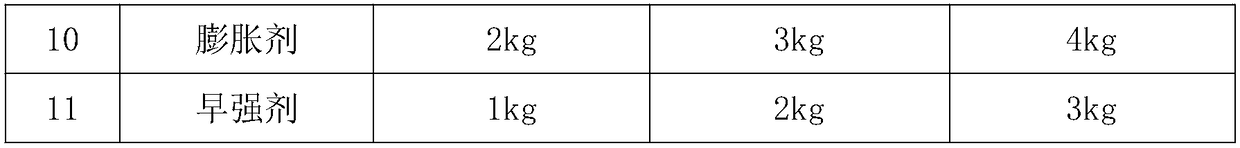

Embodiment 1

[0031] The preparation process of the above-mentioned activated slag powder is as follows: take 20kg of raw material blast furnace slag, ball mill the fineness to 300μm, then add 4% ethylenediamine phosphate and 3% ammonium chloride of slag mass, and dissolve in hot water at 65°C , stir and mix evenly, then add hydrogen peroxide solution equivalent to 10% of slag mass and 30% concentration, mix evenly, put it in the reaction pool, control the reaction temperature at 60°C, the reaction time is 8h, and finally filter to obtain.

[0032] The preparation process of the above-mentioned modified sepiolite powder is as follows: take 10kg of sepiolite, ball-mill it through a 40-mesh sieve, transport it to a calciner, calcinate it at a temperature of 540°C for 80min, cool it in air to 45°C, and place it at a concentration of Stir in 8% acetic acid solution for 20 minutes, then soak for 2.5 hours, then filter, wash with deionized water until neutral, add glyceryl monostearate equivalent ...

Embodiment 2

[0042] The preparation process of the above-mentioned activated slag powder is as follows: take 25kg of raw material blast furnace slag, ball mill the fineness to 200μm, then add 6% ethylenediamine phosphate and 4% ammonium chloride by mass of the slag, and dissolve in hot water at 70°C , stir and mix evenly, then add hydrogen peroxide solution equivalent to 15% of slag mass and 33% concentration, mix evenly, put it in the reaction tank, control the reaction temperature at 65°C, the reaction time is 9h, and finally filter to obtain.

[0043] The preparation process of the above-mentioned modified sepiolite powder is as follows: take 15kg of sepiolite, ball-mill it through a 50-mesh sieve, transport it to a calciner, and calcinate it at a temperature of 560°C for 90min, cool it to 50°C in air, and place it at a concentration of Stir in 10% acetic acid solution for 25 minutes, then soak for 3 hours, then filter, wash with deionized water until neutral, add glyceryl monostearate e...

Embodiment 3

[0053] The preparation process of the above-mentioned activated slag powder is as follows: take 30kg of raw material blast furnace slag, ball mill the fineness to 300μm, then add 8% ethylenediamine phosphate and 5% ammonium chloride of slag quality, and dissolve in hot water at 75°C , stir and mix evenly, then add hydrogen peroxide solution equivalent to 20% of the slag mass and 36% concentration, mix evenly, place in the reaction tank, control the reaction temperature at 70°C, the reaction time is 10h, and finally filter to obtain.

[0054] The preparation process of the above-mentioned modified sepiolite powder is as follows: take 20kg of sepiolite, ball-mill it through a 60-mesh sieve, transport it to a calciner, and calcinate it at a temperature of 580°C for 100min, air-cool it to 55°C, and place it at a concentration of Stir in 12% acetic acid solution for 30 minutes, then soak for 3.5 hours, then filter, wash with deionized water until neutral, add glyceryl monostearate e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com