Preparation method of refractory moisture-proof wheat straw board

A wheat straw board and refractory technology, applied in the jointing of wooden veneers, flat products, manufacturing tools, etc., can solve the problems of easy moisture absorption, rough surface, fire prevention, poor heat resistance, etc., to improve thermal stability, The effect of heat reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

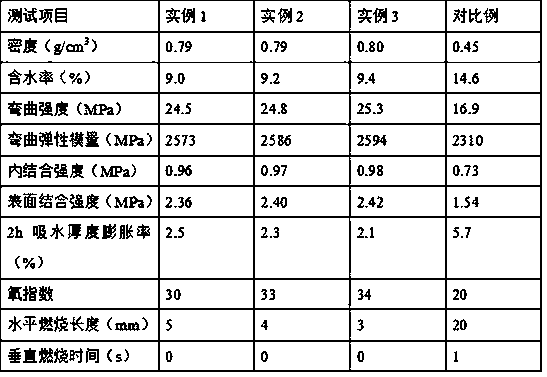

Examples

example 1

[0027] Mix rice straw and wheat straw with a mass ratio of 1:5, put them into a pulverizer and pulverize them for 4 hours, pass through a 200-mesh sieve to obtain wheat straw scraps, take trimethylmethoxysilane with 2% mass of wheat straw scraps, and use Dissolve trimethylmethoxysilane in acetone to prepare a trimethylmethoxysilane solution with a mass fraction of 5%, mix wheat straw scraps and burnt rice husk ash at a mass ratio of 5:1, and then Soak in trimethylmethoxysilane solution, soak for 4 hours at room temperature, filter, remove the filtrate to obtain modified straw fragments; mix 70g of modified straw fragments, 20g of bamboo fiber, and 100mL of water to obtain straw slurry, and The straw slurry was injected into a forming tank equipped with a vacuum dehydration device. After air bubbling and stirring for 10 seconds, it was left to stand for vacuum dehydration for 5 minutes. When the dehydration was controlled, the vacuum degree was 70 Pa to obtain a straw wet moldin...

example 2

[0029] Mix rice straw and wheat straw at a mass ratio of 1:5, put them into a pulverizer and pulverize them for 4.5 hours, pass through a 200-mesh sieve to obtain wheat straw scraps, take trimethylmethoxysilane with 2% mass of wheat straw scraps, Dissolve trimethylmethoxysilane with acetone to prepare a trimethylmethoxysilane solution with a mass fraction of 5%, mix wheat straw scraps and rice husk burnt ash in a mass ratio of 5:1, Then soak in trimethylmethoxysilane solution, soak at room temperature for 4.5h, filter, remove the filtrate to obtain modified straw fragments; mix 75g of modified straw fragments, 25g of bamboo fiber, and 110mL of water to obtain straw slurry , inject the straw slurry into the molding tank with a vacuum dehydration device, after air bubbling and stirring for 13s, let it stand for vacuum dehydration for 7min, and control the vacuum degree of 75Pa during dehydration to obtain a straw wet molded body; add 110g polyphosphoric acid to the beaker Ammoni...

example 3

[0031] Mix rice straw and wheat straw at a mass ratio of 1:5, put them into a pulverizer and pulverize them for 5 hours, pass through a 200-mesh sieve to obtain wheat straw scraps, take trimethylmethoxysilane with 2% mass of wheat straw scraps, and use Dissolve trimethylmethoxysilane in acetone to prepare a trimethylmethoxysilane solution with a mass fraction of 5%, mix wheat straw scraps and burnt rice husk ash at a mass ratio of 5:1, and then Soak in trimethylmethoxysilane solution, soak for 5 hours at room temperature, filter, remove the filtrate to obtain modified straw fragments; mix 80g of modified straw fragments, 30g of bamboo fiber, and 120mL of water to obtain straw slurry, and The straw slurry was injected into a molding tank with a vacuum dehydration device, and after air bubbling and stirring for 15 seconds, it was left to stand for vacuum dehydration for 8 minutes. When the dehydration was controlled, the vacuum degree was 80 Pa, and a straw wet molded body was ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com