A rolling method of biomedical degradable zn-li alloy

A biomedical, zn-li technology, applied in the direction of metal rolling, temperature control, etc., can solve the problems of poor mechanical properties of degradable polymer materials, aggravate the mental and economic burden of patients, and limited application range, etc. Large-scale industrial production, low cost, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

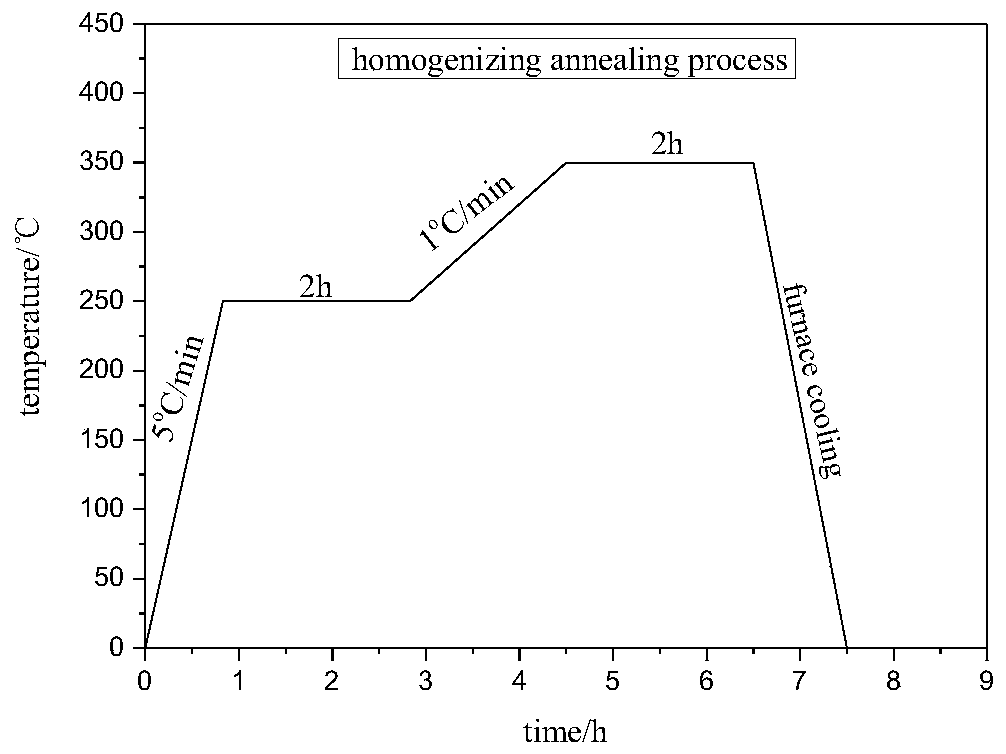

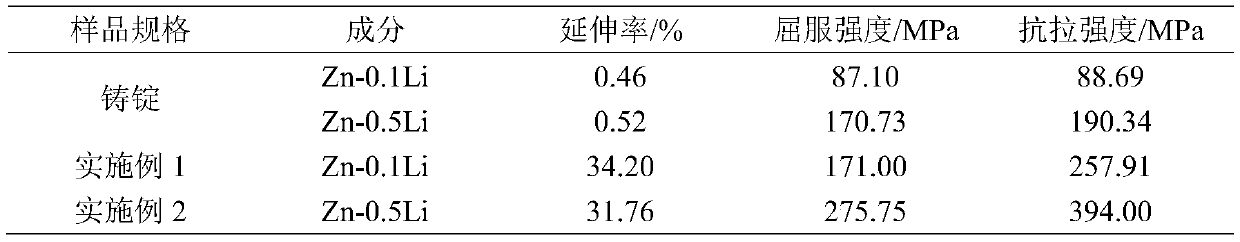

[0023] Homogenization treatment: place the Zn-0.1(wt%) Li alloy ingot in a box-type heating and sintering furnace KSL-1400X, heat up to 200°C at a rate of 2°C / min, and keep it for 1 hour; then heat it at 0.5°C / min Raise the temperature to 300°C at a certain speed and keep it warm for 1 hour; cool down with the furnace.

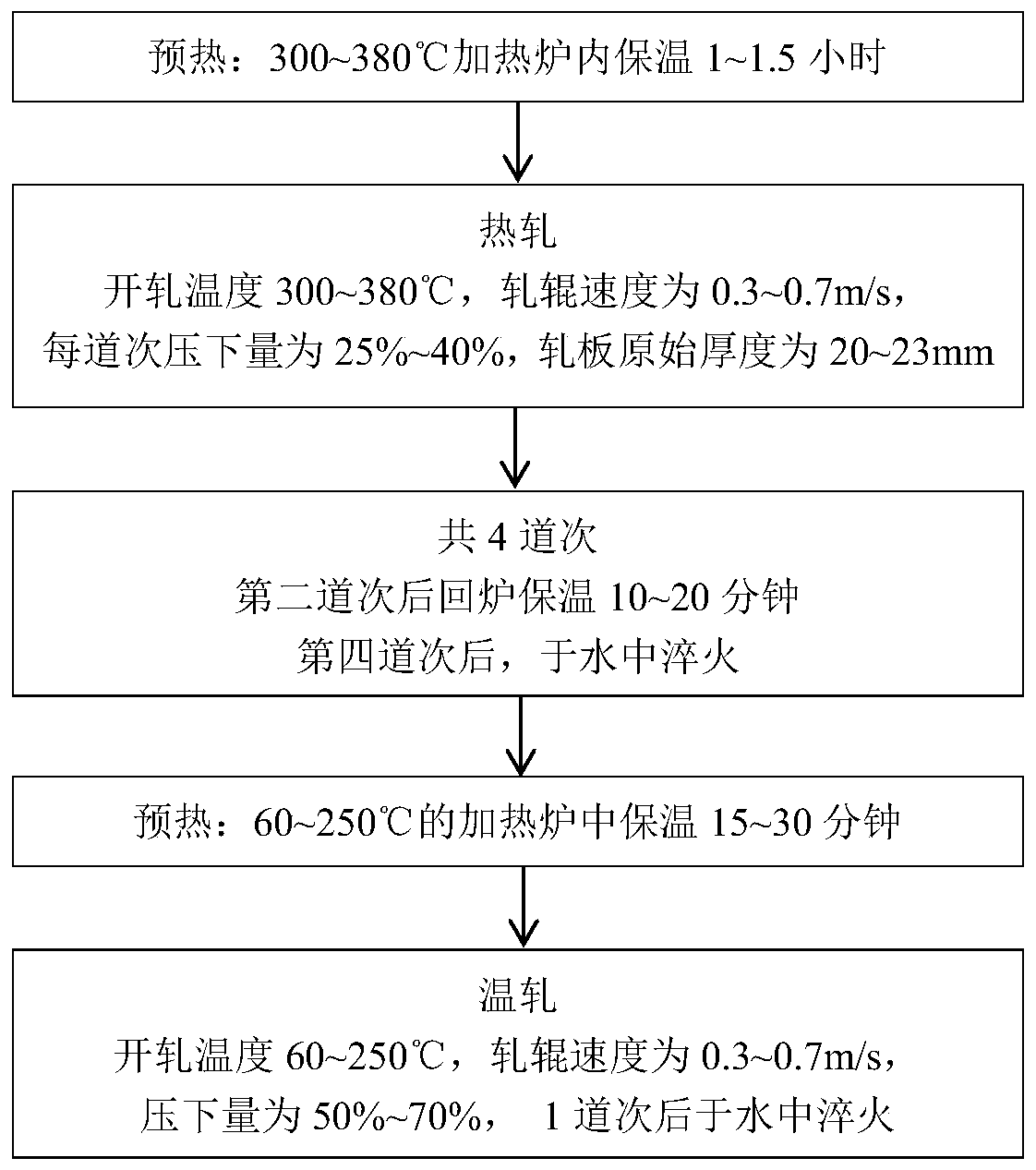

[0024] Preheating: heat the ingot at 300°C for 1 hour.

[0025] Hot rolling: start rolling temperature is 300℃, roll speed is 0.3m / s; the first pass, the alloy sample with a thickness of 21mm is rolled to a thickness of 18mm; the second pass, the alloy sample is rolled to 13mm; minutes; the third pass, the alloy sample was rolled to 10mm; the fourth pass, the alloy sample was rolled to 6mm; quenched in water;

[0026] Warm rolling: place the hot-rolled and quenched sample in a heating furnace at 70°C and keep it warm for 20 minutes; the rolling start temperature is 70°C, the roll speed is 0.3m / s, and the alloy sample is rolled to a thickness of 3mm in one pas...

Embodiment 2

[0028] Homogenization treatment: place the Zn-0.5 (wt%) Li alloy ingot in a box-type heating and sintering furnace KSL-1400X, heat up to 260°C at a rate of 4°C / min, and keep it for 2 hours; then heat it at 0.7°C / min The temperature is raised to 330°C at a certain speed, and the temperature is kept for 2 hours; it is cooled with the furnace.

[0029] Preheating: heat the ingot at 330°C for 1.5 hours.

[0030] Hot rolling: start rolling temperature is 330℃, roll speed is 0.5m / s; the first pass, the alloy sample with a thickness of 18mm is rolled to a thickness of 14mm; the second pass, the alloy sample is rolled to 10mm; minutes; in the third pass, the alloy sample was rolled to 7 mm; in the fourth pass, the alloy sample was rolled to 4 mm; quenched in water.

[0031] Warm rolling: place the hot-rolled and quenched sample in a heating furnace at 200°C for 30 minutes; start rolling at a temperature of 200°C and a roll speed of 0.5m / s, and roll the alloy sample in one pass to a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com