A kind of chitosan modified bioceramic material and preparation method thereof

A bio-ceramic material, chitosan modification technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problem of large molecular weight of chitosan, improve compressive strength, improve compressive strength and, The effect of promoting in vitro biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1) Preparation of CPP base material: Pour 100g of calcium dihydrogen phosphate raw material into a clean crucible. The upper part of the crucible should be covered but not sealed. ℃, heat preservation for 10h to carry out primary sintering, after the furnace cools down, take out the powder material for primary sintering, grind it into powder, then mix these powders with 1g of polyvinyl alcohol with a mass fraction of 5% to obtain a mixture, according to the ball water 1: Pour the ratio of 2:1 into a ball mill tank and mill at a speed of 230r / m for 60min. Dry the milled slurry at 50°C and pass it through a 200-mesh sieve. Mix 3:7 evenly, carry out dry pressing molding, and obtain the green body; finally, the pressed green body is raised to 400°C at a rate of 4°C / min and kept for 2h, and raised to 850°C at a rate of 4°C / min. Keep warm for 90 minutes, cool naturally with the furnace, take it out, and the porous CPP ceramic material is obtained.

[0066] 2) Pretreatment of...

Embodiment 2

[0070] 1) Preparation of CPP base material: Same as Example 1.

[0071] 2) Pretreatment of CPP base material: same as embodiment 1.

[0072] 3) preparation of chitosan sol: with embodiment 1

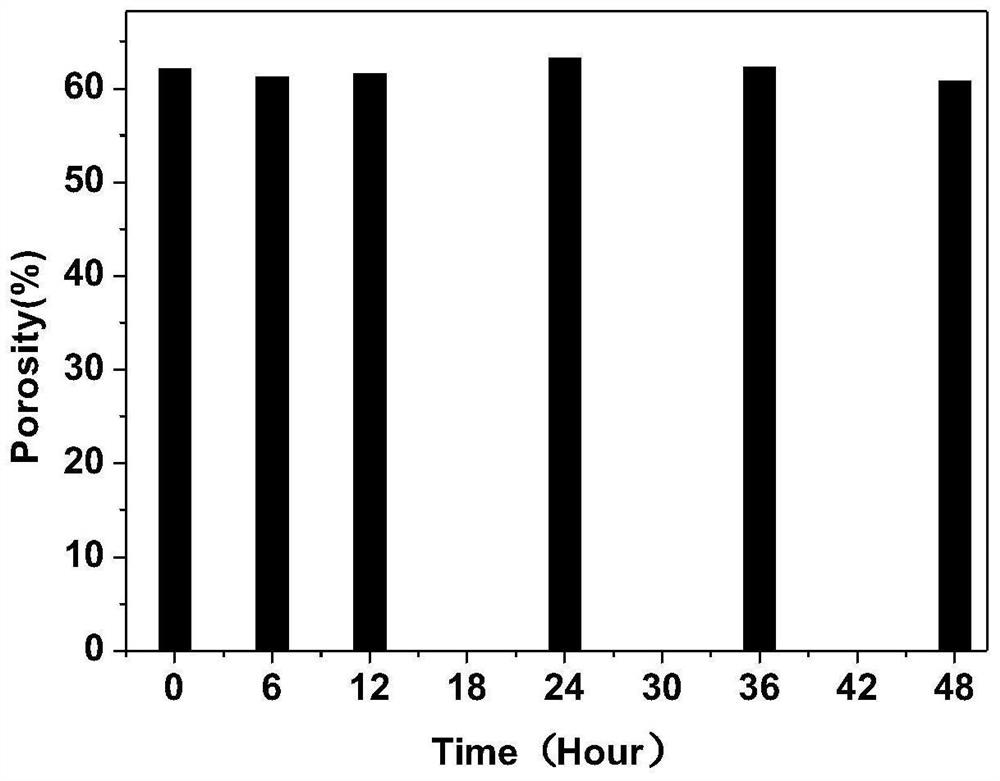

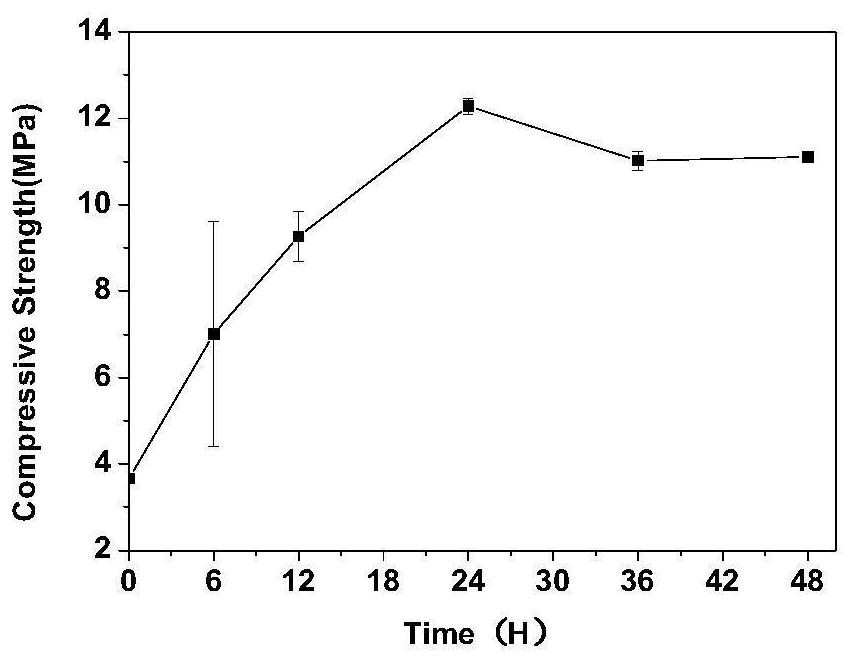

[0073] 4) Preparation of composite bioceramic material: take the chitosan solution prepared in step 3) as the immersion solution, and immerse the CPP base material obtained in step 2) into the immersion solution under a constant temperature water bath condition of 40°C, Soak for 6h, 12h, 24h, 36h, 48h respectively, then ultrasonically oscillate in the soaking solution for 5min, take it out and dry it at 55°C for 6h, then use 0.1mol / L NaOH solution, deionized water, and absolute ethanol to remove residual impurities , dried, that is.

Embodiment 3

[0075] 1) Preparation of CPP base material: Pour 100g of calcium dihydrogen phosphate raw material into a clean crucible. The upper part of the crucible should be covered but not sealed. ℃, keep warm for 15 hours for primary sintering, take out the primary sintered powder after the furnace cools down, grind it into powder, and then mix these powders with 0.1g of polyvinyl alcohol with a mass fraction of 10% to obtain a mixture, according to the ball water 1 Pour the ratio of 1:1 into a ball mill tank and mill at a speed of 300r / min for 20min, dry the milled slurry at 45°C and pass it through a 100-mesh sieve. Ratio 3:7 mixed evenly, carry out dry pressing molding (the condition of pressing molding is: pressure is 0.5MPa, hold pressure 2min), obtain green body; Hold at 300°C for 4 hours, raise to 700°C at a rate of 1°C / min, hold for 120 minutes, wait for the furnace to cool naturally, take it out, and the porous CPP ceramic material is obtained.

[0076] 2) Pretreatment of CPP...

PUM

| Property | Measurement | Unit |

|---|---|---|

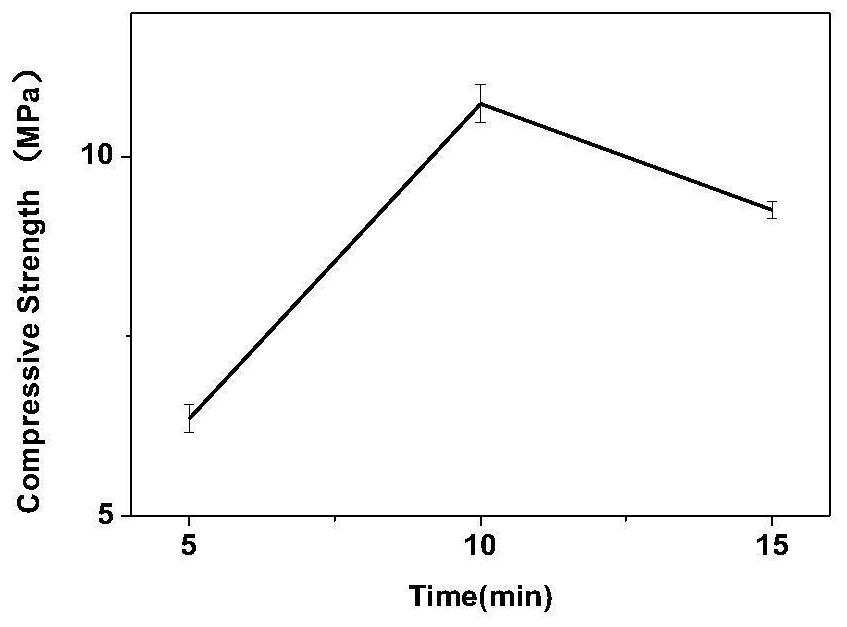

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com