Resource utilization method of titanium chloride slag and device thereof

A titanium chloride, resource recovery technology, applied in the field of titanium dioxide chemical industry, can solve the problems of increasing investment and operating costs, consuming large energy, failing to achieve salt and light brine, etc., and achieve obvious economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

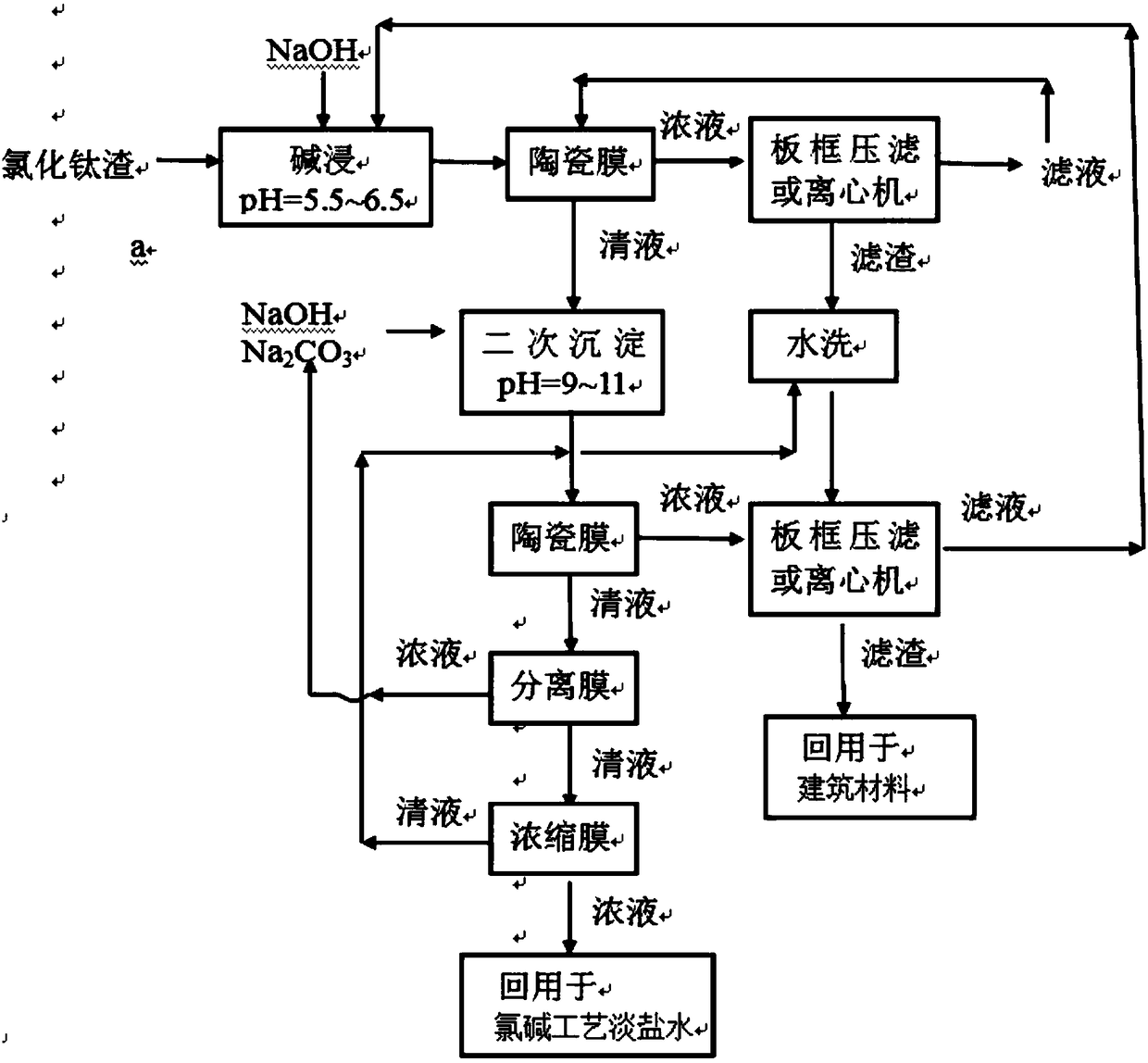

[0078] as per figure 1 Operate as shown in the process flow chart.

[0079] Leach 60kg of titanium chloride slag with sodium hydroxide alkaline solution, adjust the pH=6 at the same time, control the solid-liquid ratio to 1:15 (weight ratio), stir and react for 10 hours, and form a neutralized slurry; for the neutralized slurry, first use Filter the supernatant with a ceramic membrane, and when the solid content in the ceramic membrane dope reaches 3%, discharge the dope and neutralize the slag bottom liquid with a plate and frame filter press or a centrifuge for solid-liquid separation to obtain solids And slag, the ceramic membrane clear liquid enters the secondary precipitation process as the neutralization filtrate, and the plate and frame filtrate returns to the ceramic membrane for filtration again. Now neutralize the content of sodium chloride in filtrate and be 5361mg / L, volume is 850l, impurity Al, Si content are respectively 0.146mg / L, 0.404mg / L;

[0080] Wash the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com