Steel, carburized steel component, and carburized steel component production method

A technology of carburizing steel and parts, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of reduced cold forgeability, and achieve the effects of excellent machinability, low-cost manufacturing, and excellent cold forgeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

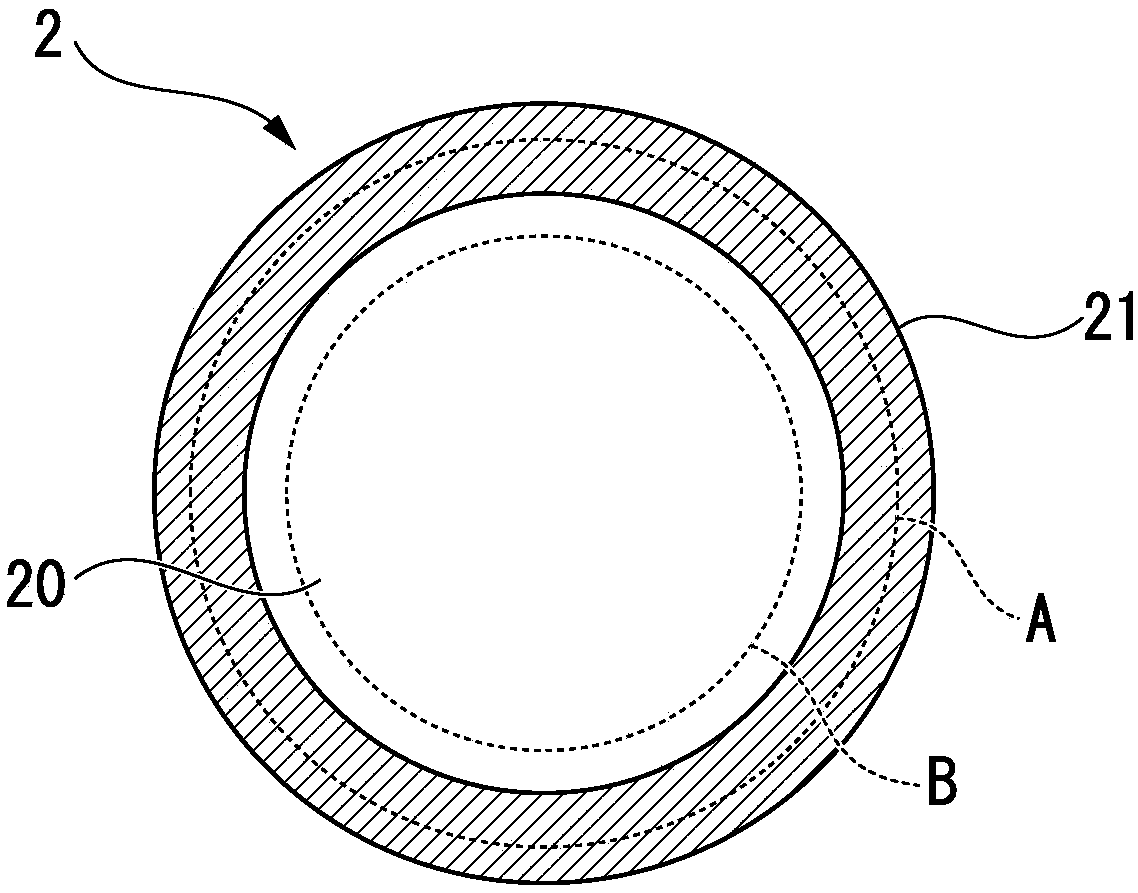

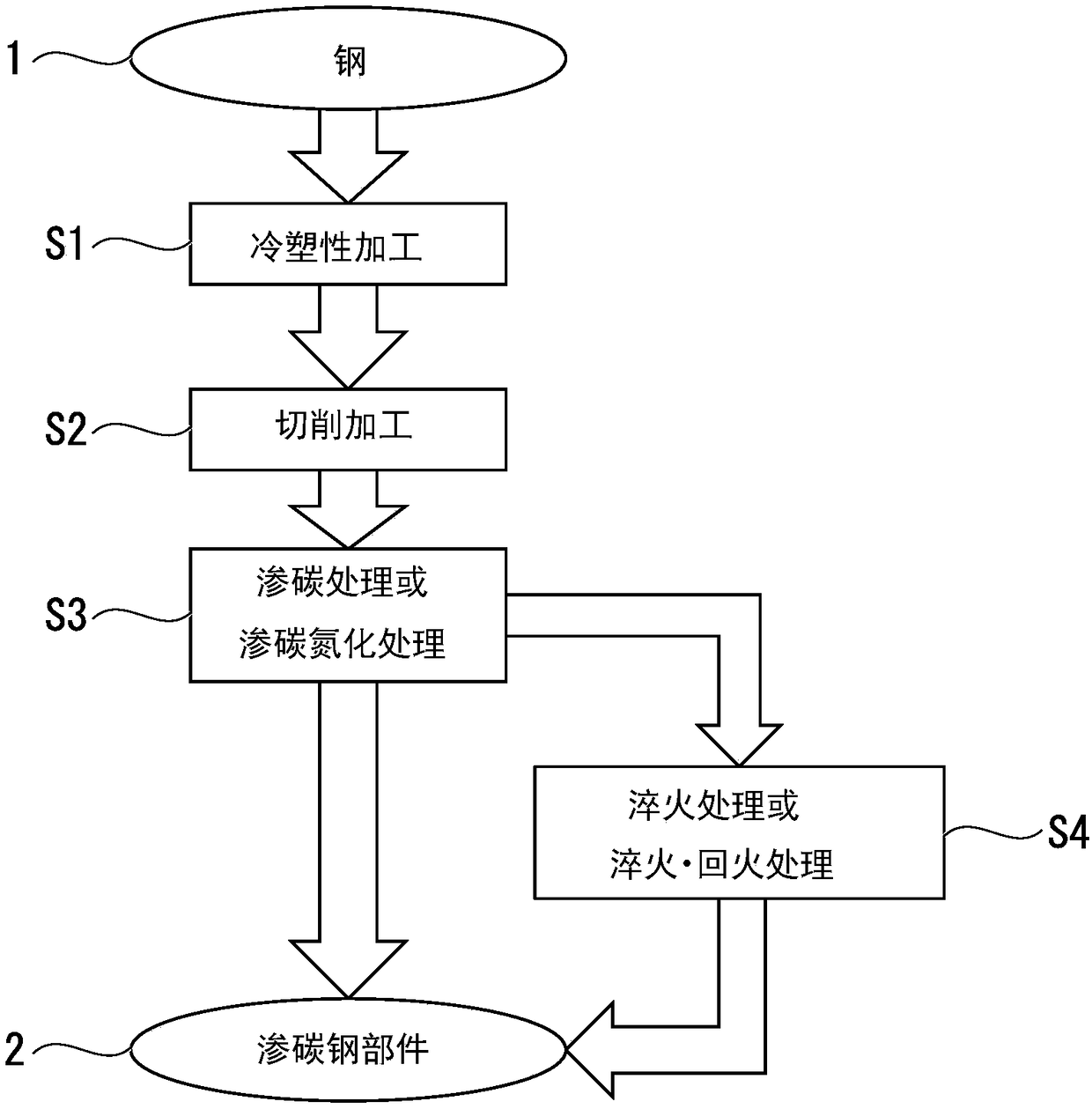

Image

Examples

Embodiment 1

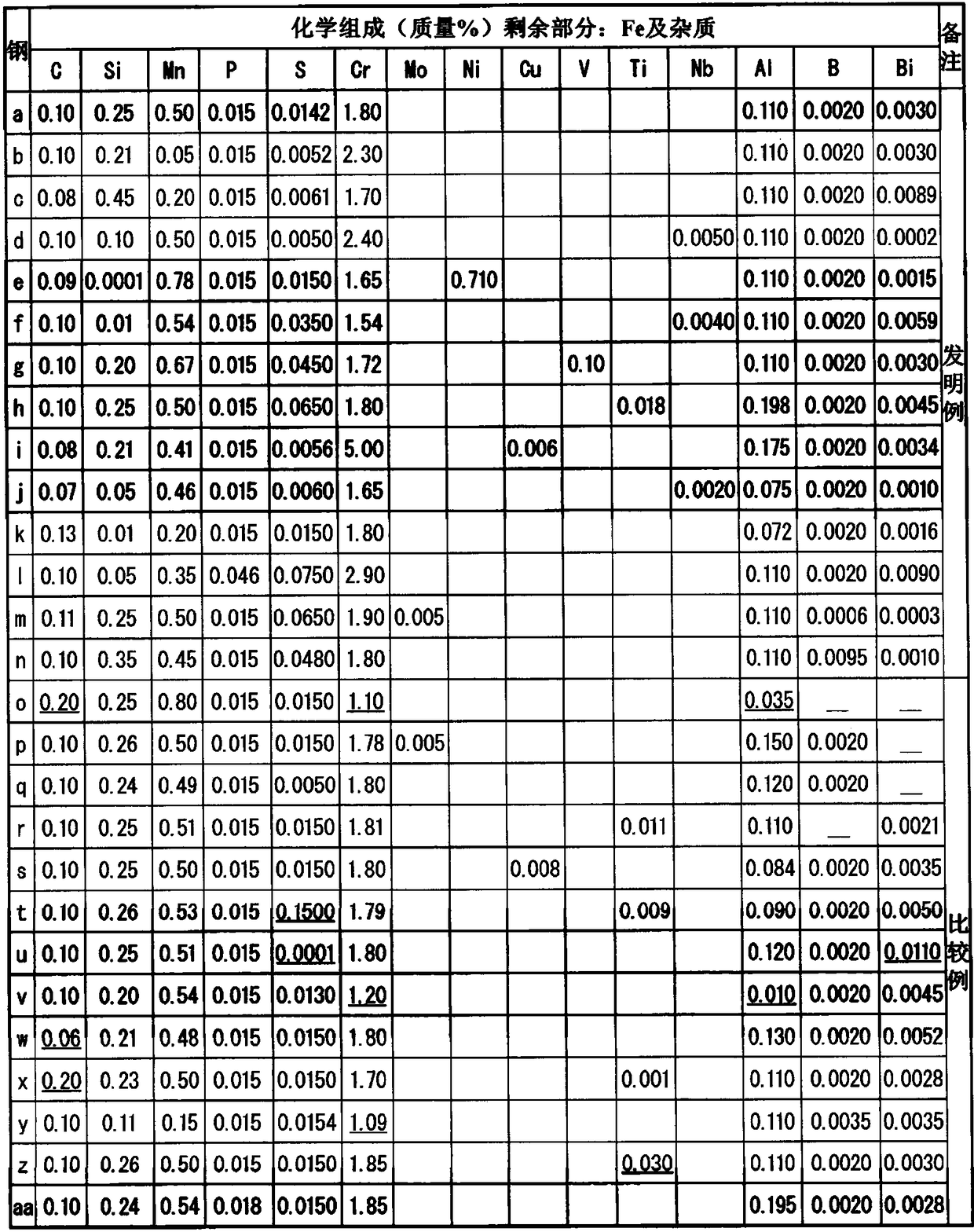

[0179] Steels a to aa having the chemical compositions shown in Table 1A and Table 1B were melted in a 270-ton converter, and continuous casting was performed using a continuous casting machine to produce a 220×220 mm square slab. Here, the superheat of the molten steel in the tundish is set to 30°C, and the casting speed is set to 1.0 m / min.

[0180] In the continuous casting of the cast slab, the average cooling rate in the temperature range from the liquidus temperature to the solidus temperature at a depth of 15 mm from the surface of the cast slab was performed by changing the cooling water volume of the mold control. By operating in this way, casting slabs a to aa having the chemical compositions shown in Table 1A and Table 1B were continuously cast. For the slab o, the slab p, and the slab q, the primary arm spacing of the dendrites within a range of 15 mm from the surface layer reached 600 μm or more. In other cast slabs, the dendrite primary arm interval within a range...

Embodiment 2

[0242] Except for the average cooling rate in the temperature range from the liquidus temperature to the solidus temperature (hereinafter referred to as the "average cooling rate") at a depth of 15 mm from the surface of the cast slab, it is comparable to steel a and steel Under the same manufacturing conditions as g, steel for carburization having the same chemical composition as steel a and steel g was produced, and various evaluations were performed on these steel for carburization by the same method as steel a and steel g. The average cooling rate was set to the value shown in Table 3.

[0243] [table 3]

[0244]

[0245] As shown in Table 3, test numbers 1 and 7 in which the average cooling rate is within the range of 100 to 500°C have the hardness, ultimate compressibility, and clearance surface wear before carburization because the sulfide is appropriately finely dispersed. The amount and chip weight are within the acceptable range, and the carburized layer thickness, carbu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com