A high power fiber optic circulator based on curved fiber end cap

An optical fiber circulator and optical fiber end technology, which is applied to the coupling of optical waveguides, instruments, optics, etc., can solve the problems of limiting the power bearing capacity of the device, low coupling efficiency, and difficult installation and adjustment, and achieves lower temperature, high coupling efficiency, The effect of increasing the damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] figure 1 It is the structure diagram of the optical fiber end cap based on the curved surface optical fiber end cap of the present invention, such as figure 1Said, including optical fiber (11) and end cap (12) and end cap curved surface (12-1), the radius of the curved surface of end cap is R, and end cap is cylindrical, and the output end surface of end cap is coated with anti-reflection film, for example: AR coating is SiO 2 , the coating band needs to match the working wavelength of the fiber optic circulator. The optical fiber and the curved end cap are connected through an integrated fusion splicing process. The optical fiber and the end cap are coaxial to ensure that the speed of light does not shift after entering, and the quality of the spot is improved, thereby improving the coupling efficiency.

[0049] The radius of curvature R of the curved surface of the end cap needs to meet the following conditions:

[0050]

[0051] The radius of the laser beam wai...

Embodiment 2

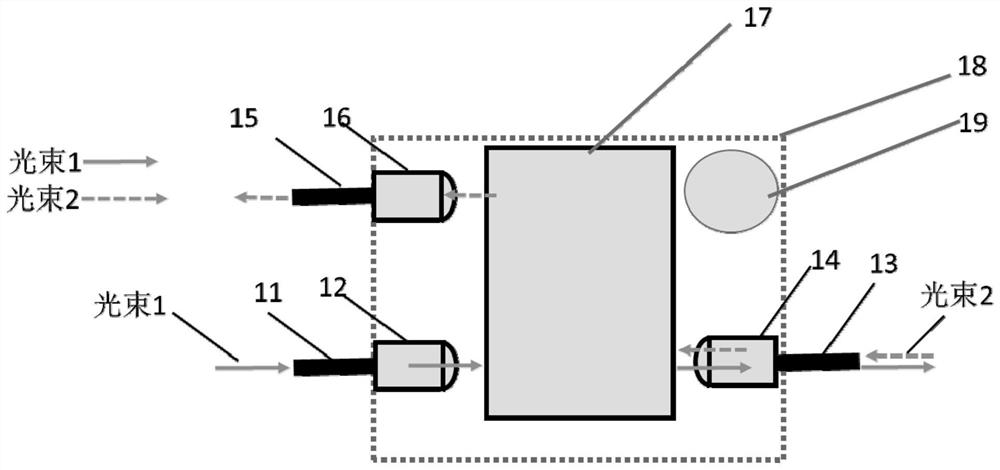

[0057] see image 3 , the fiber optic circulator includes an optical fiber (11) and an end cap (12), an optical fiber (13) and an end cap (14), an optical fiber (15) and an end cap (16), a circulator core (17), a substrate (18), Heat sink and thermal management system (not shown in the figure). The optical fiber (11) is connected to the end cap (12), the optical fiber (13) is connected to the end cap (14), the optical fiber (15) is connected to the end cap (16), and the circulator core (17) is installed on the base plate (18), A heat dissipation device (19) and a heat management system are installed on the base plate. The circulator core includes at least one of a polarization beam splitter, a birefringent crystal, a wave plate, a rotator, and a beam shifter, or a combination thereof, and its circulator core (17) can make the beam entering it deflect or Displacement; The manufacturing method and conditions of the optical fiber and the end cap are the same as in embodiment 1,...

Embodiment 3

[0062] The manufacturing method and conditions of the optical fiber and the end cap used in this implementation are the same as those in Embodiment 1.

[0063] see Figure 4 , the optical fiber circulator comprises an optical fiber (11) and an end cap (12), an optical fiber (13) and an end cap (14), an optical fiber (15) and an end cap (16), an optical circulator core (104), a cooling device (Fig. not shown), the optical circulator core (104) includes a polarization beam splitter (100), a Faraday rotator (101), a wave plate (102), and a polarization beam splitter (103).

[0064] Beam 1 enters the optical fiber (11) and expands into a collimated beam through the curved surface of the end face (12), enters the circulator core, and then enters the curved surface of the end cap (14) to be coupled to the tail core output of the optical fiber (13), and the light beam 2 enters the optical fiber ( 13) After the curved surface of the end face (14) expands into a collimated beam, it en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com