Photoelectric receiver-transmitter integrated module assembly of mono-optical fibre two-way

A photoelectric transceiver, single-fiber bidirectional technology, applied in the direction of electromagnetic transceivers, electrical components, optical fiber transmission, etc., can solve the problems of increasing the size of the connection port, the conflict of the minimum weldable size, and the narrow space, so as to achieve the increase of laser power and laser The effect of excellent power loss and meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

Example one:

The structure diagram of a specific embodiment of the present invention is shown in FIG. 4, the transmitting end 1 and the receiving end 2 are placed side by side, and the principle of the optical path is shown in FIG. 5, and the optical path propagates through the optical lens group 3. The optical lens group 3 includes a first total reflection glass plate 31, a focusing lens 34, a second total reflection glass plate 33, and a filter 32. The first total reflection glass plate 31 and the second total reflection glass plate 33 are placed in parallel, a focusing lens 34 is placed between the two, the first total reflection glass plate 31 is placed at an angle of 45 degrees to the incident light direction, and the second total reflection glass plate A filter 32 is placed between the glass slide 33 and the receiving end 2, and the filter 32 can also be placed between the first total reflection glass plate 31 and the second total reflection glass plate 33. When transmitting...

Example Embodiment

Embodiment two:

Fig. 7 is a divergence diagram of the optical path when the focusing lens 34 is not added in the specific embodiment of the present invention. Under the structure of two total reflection glass slides in this example, the laser can reach the receiving end after two total reflections and one filtering. The stroke in the air is greatly increased, so that the power of the laser suffers a greater loss, and due to the long divergence distance, the average area power is reduced, which is inferior to the solution of the first embodiment in terms of receiving sensitivity.

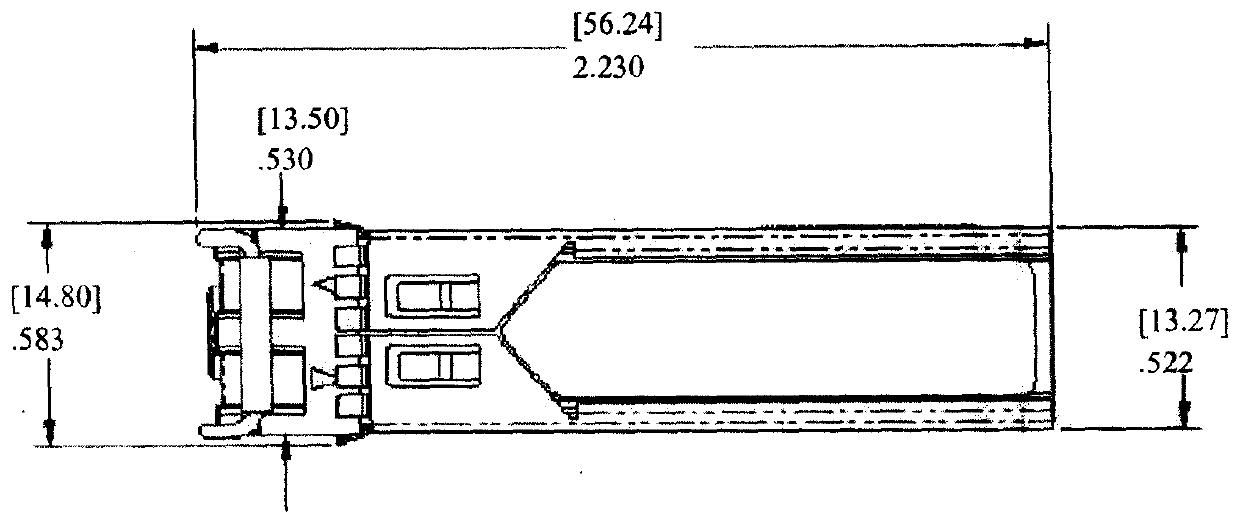

The single-fiber bidirectional module of the present invention fully meets national and international standards in terms of main performance such as power and sensitivity, and is completely compatible with the current SFP standard module in appearance, and achieves miniaturization while ensuring performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com