Detection method of hydraulic cylinder

A technology of a hydraulic cylinder and a detection method, which is applied in the field of hydraulic cylinder detection, can solve the problems of difficulty in detecting tiny leaks of seals, leakage of oil cylinders, and low detection rate of unqualified products, and achieves low production and maintenance costs. The effect of reducing the failure rate, convenient and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A hydraulic cylinder detection method of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

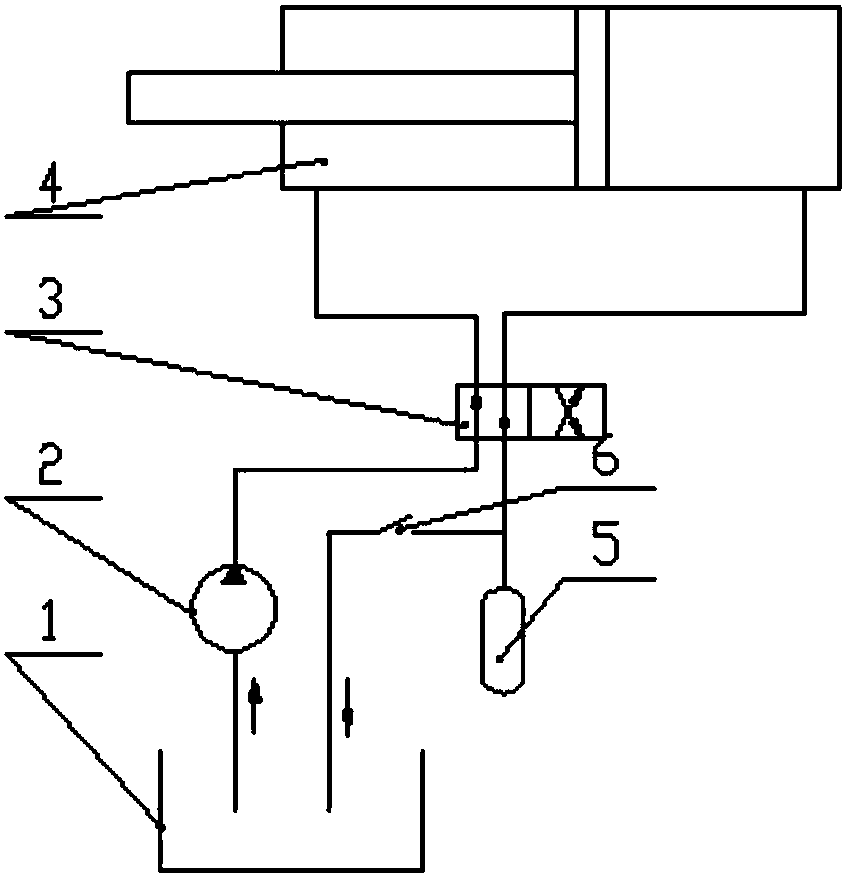

[0016] figure 1 As shown, a hydraulic cylinder detection method of the present invention is based on the existing no-load hydraulic cylinder detection pressure test bench, after connecting a tee on the oil return pipeline behind the electromagnetic reversing valve 3, and connecting the ball valve 6 all the way It is then connected to the oil return tank 1, and the other road is connected to the accumulator 5 as a load source to realize artificially adding controllable pressure in the corresponding cavity of the hydraulic cylinder 4 to simulate the load. The accumulator is a piston type accumulator, model HXQ-L20 / 31.5, it is a kind of hydraulic isolation accumulator, its working principle is to use the compressibility of gas, separate the gas and liquid through the piston, and pre-charge the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com