A test method for simulating passive failure of excavation face of shallow buried shield tunnel

A passive destruction technology for shield tunnels, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problem that there are few model tests for passive destruction of shallow buried shield tunnels, and achieve scientific model test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] Implementation method and effect:

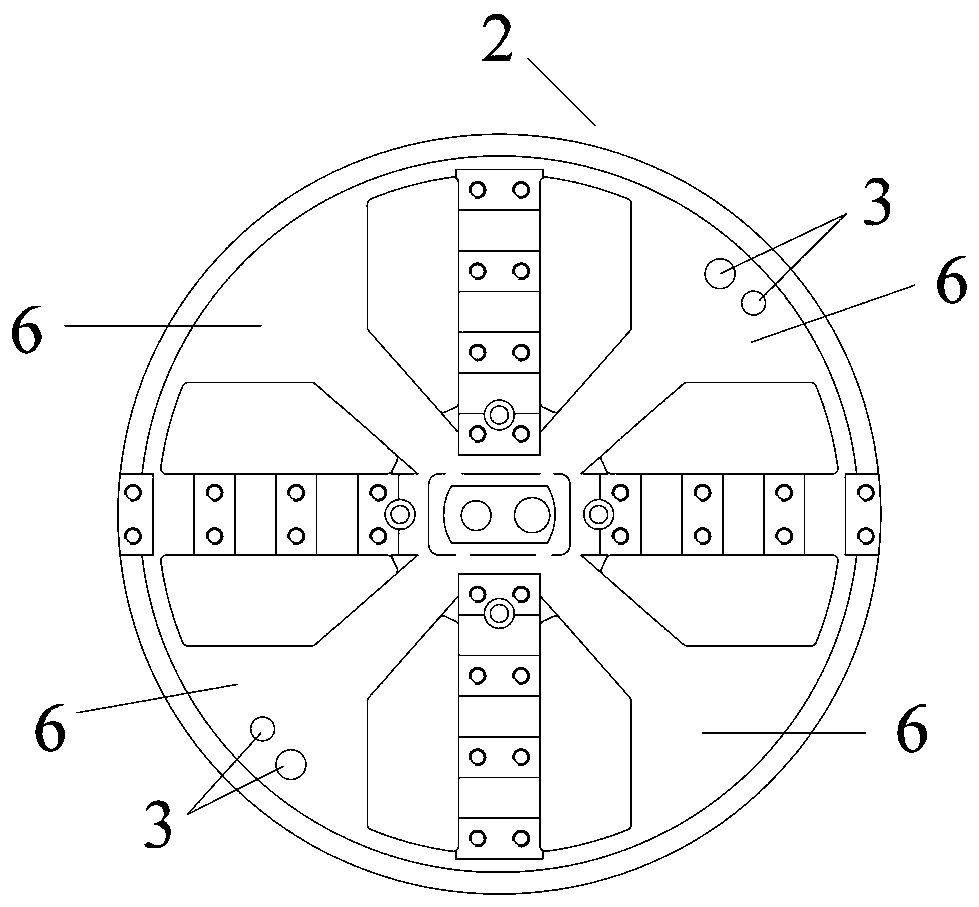

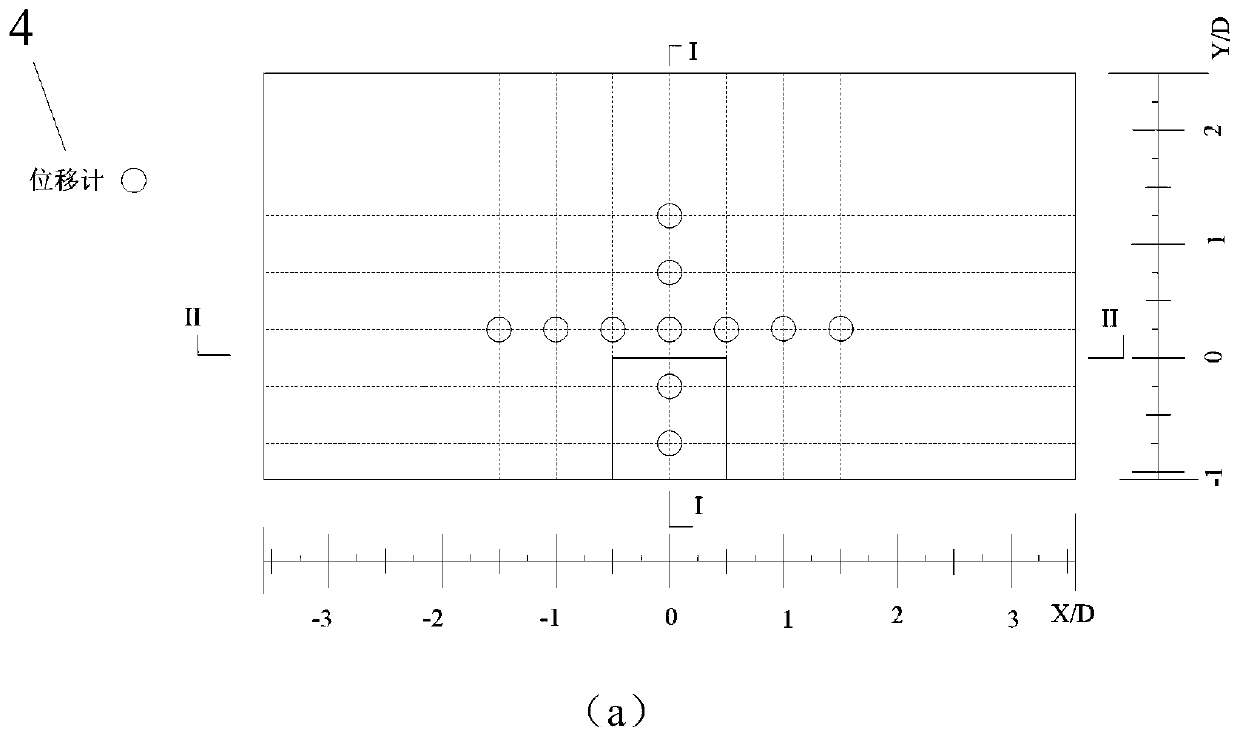

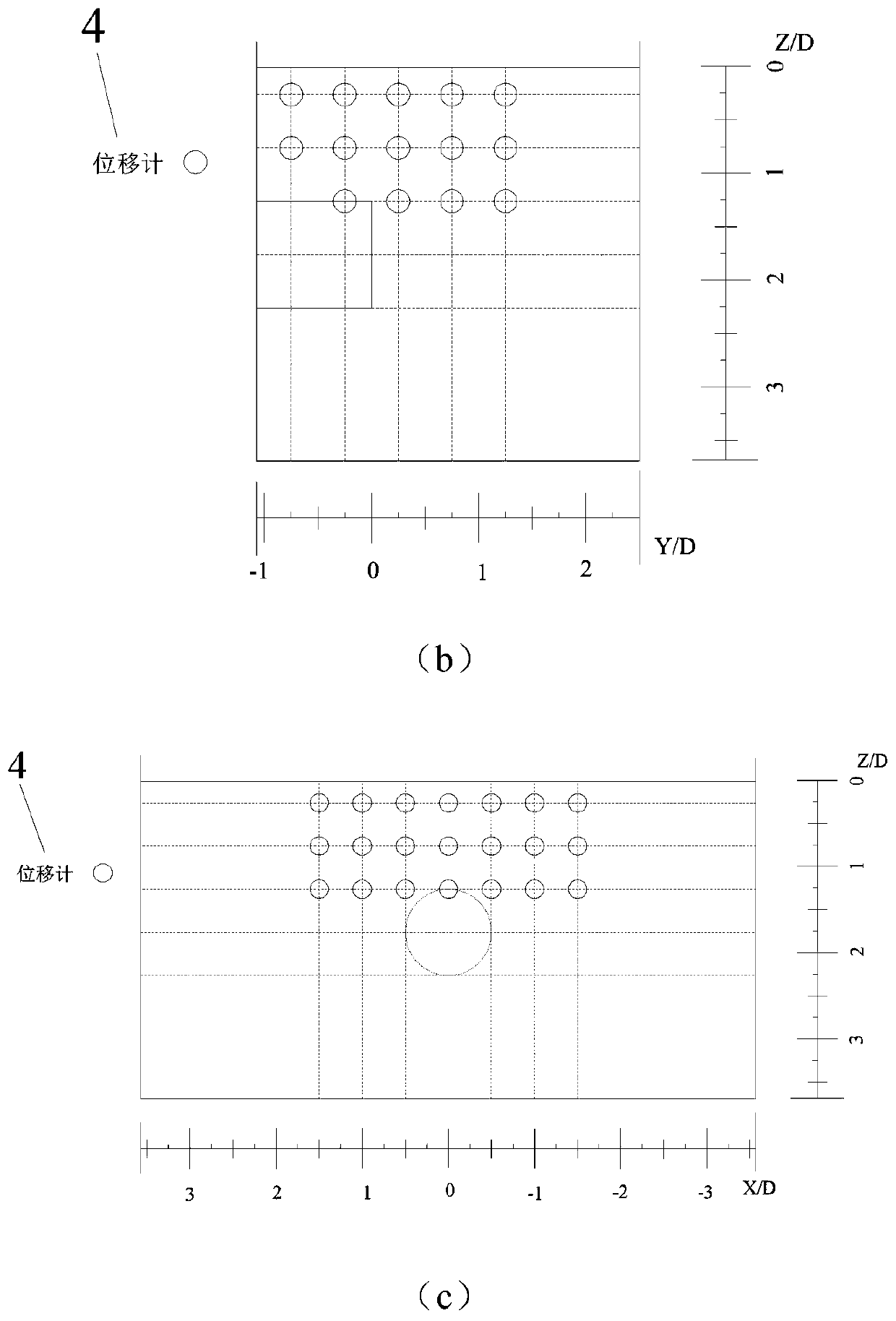

[0043] The above example of the present invention, through the method of installing miniature earth pressure gauge and miniature osmometer on the cutter head of the model shield machine, pre-buried grating ruler displacement gauge in front of the excavation face, and buried LVDT displacement gauge on the ground surface, a kind of simulated shallow burial is completed. The monitoring plan for the test method of passive damage to the excavation surface of the shield tunnel; through the test method of rotating the cutter head of the model shield machine, driving the model shield machine, and preventing the excavation of the screw excavator, the passive damage of the real shield excavation surface is simulated. process. From this, the limit support force on the excavation face of the model shield machine, the soil damage area in front of the excavation face and the surface uplift range can be obtained. The invention can be used for simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com