Resin composition and low-gummosis prepreg prepared from resin composition

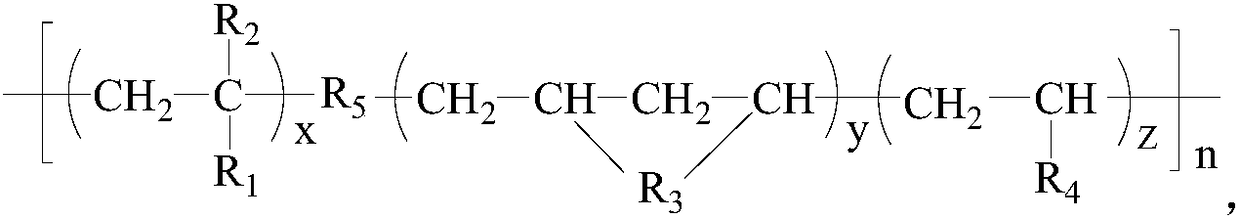

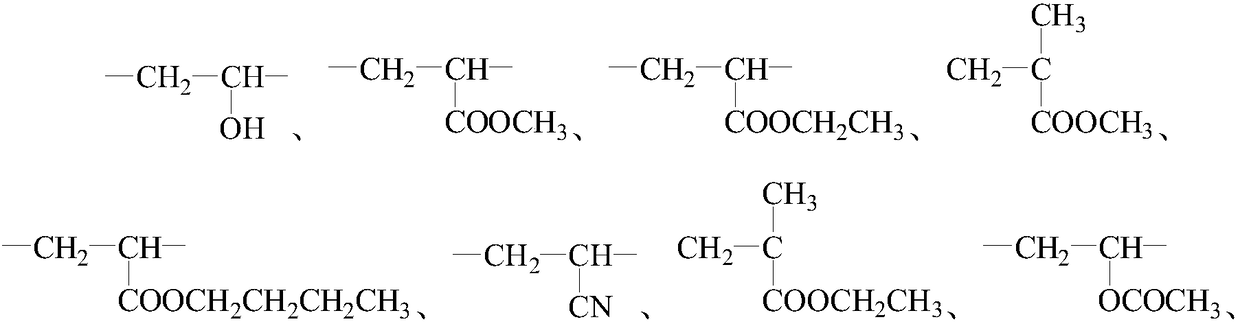

A resin composition and resin curing technology, applied in the field of low-flow glue prepreg, can solve the problems of insufficient adhesive force, large amount of glue overflowing from the prepreg, and influence of the prepreg, and achieve the effects of good stability, control and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0061] In a dry three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 400 g (4.65 mol) of vinyl acetate after purification, 0.1 g AIBN and 250 mL of acetone, and heat in a water bath under stirring, controlling the temperature of the water bath to be 50- Keep reflux at 65°C; after a period of time, the reactant in the flask becomes viscous and accompanied by bubbles. When the bubbles in the reactant basically no longer rise and become thin strips, add 250mL acetone to the flask And continue to stir, stop the reaction when the viscosity of the mixture in the flask is almost constant. The mixture in the flask was poured out, washed with water, filtered, and then dried in a constant temperature oven at 100°C for 12 hours to obtain a vinyl acetate polymer. Then, get this copolymer 100g, use 100mL acetone to dissolve and pour in the flask and keep stirring, then add 150mL methanol and NaOH methanol solution 50mL, make the polyvinyl alcohol (PVA) solu...

Synthetic example 2

[0063] In a dry three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 400 g (4.65 mol) of vinyl acetate after purification, 0.1 g AIBN and 250 mL of acetone, and heat in a water bath under stirring, controlling the temperature of the water bath to be 50- 55°C, keep reflux. After a period of time, the reactant in the flask began to become viscous and was accompanied by the generation of bubbles. When the bubbles in the reactant basically stopped rising and became long and thin, add 250mL of acetone to the flask and continue to stir. Stop the reaction when the viscosity of the mixture is almost constant. The mixture in the flask was poured out, washed with water, filtered, and then dried in a constant temperature oven at 100°C for 12 hours to obtain a vinyl acetate polymer. Then, get this copolymer 100g, use 100mL acetone to dissolve and pour in the flask and keep stirring, then add 100mL of 150mL methanol and 2mol / l hydrochloric acid, make polyv...

Embodiment 1-8 and comparative example 1-6

[0067] According to the formula shown in Table 1 and Table 2, mix the components evenly to make a 50% resin solution, use electronic grade 2116 glass fiber cloth as a reinforcing material to impregnate the above resin solution, and then heat and cure the prepreg in an oven for a certain time Low-flow adhesive prepregs can be obtained in a short period of time. Part of the prepregs are pressed into laminates according to the following conditions, and then the properties of the prepregs and laminates are evaluated by the following methods.

[0068] Prepreg and laminate production conditions:

[0069] Prepreg semi-curing conditions: 170°C / 4min for Examples 1-8 and Comparative Examples 1, 3, 5, and 6, 180°C / 4min for Comparative Examples 2 and 4; stack: 5*2116; copper foil Thickness: 1OZ; plate thickness after forming: 0.5mm; curing conditions: temperature rise 3-5°C / min, material temperature 190°C / 1-2h.

[0070] Prepreg test items: overflow glue amount, punching edge quality, pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com