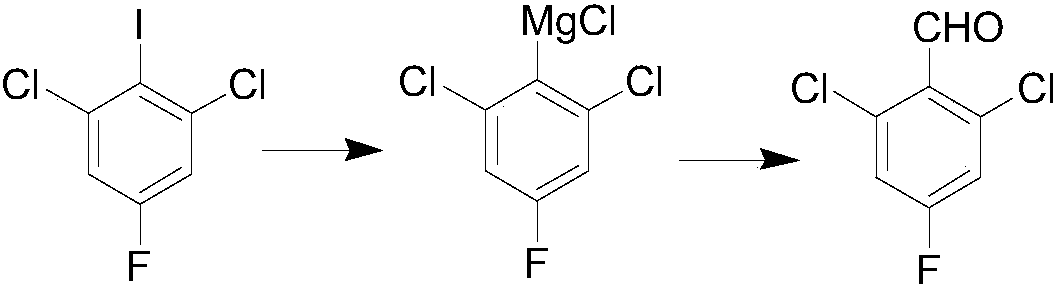

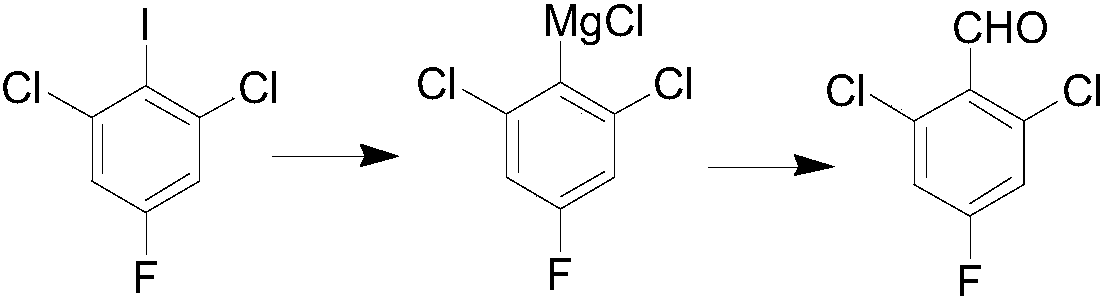

Preparation method for 2,6-dichloro-4-fluorobenzaldehyde

A technology of fluorobenzaldehyde and dichloride, which is applied in the field of preparation of 2,6-dichloro-4-fluorobenzaldehyde, can solve problems such as application limitation, low yield of benzaldehyde, pollute the environment, etc., and achieves simple operation, raw material Easy to obtain, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of isopropylmagnesium chloride Grignard reagent: first add 20 mL of tetrahydrofuran and 3 g of 2-chloropropane into a 50 mL one-necked flask and stir to make a solution, and set aside. Under the protection of nitrogen, in a 50mL dry three-necked flask, add 1.1g of magnesium chips, a small amount of 2-chloropropane, and a small amount of tetrahydrofuran solvent, raise the temperature to 30-40°C, and initiate the reaction with bromoethane. Then the tetrahydrofuran solution of 2-chloropropane was added dropwise, and after the dropwise addition was completed, an insulation reaction was carried out, and the concentration of the obtained isopropylmagnesium chloride Grignard reagent was 1.7 mol / L.

[0019] (2) Grignard exchange: under the protection of nitrogen, add 10 g of 2,6-dichloro-4-fluoroiodobenzene and 20 ml of tetrahydrofuran into a 100 ml dry three-necked flask. Cool down to 0°C, slowly add the above-prepared isopropylmagnesium chloride Grignard reage...

Embodiment 2

[0023] (1) Preparation of isopropylmagnesium chloride Grignard reagent: first add 20 mL of tetrahydrofuran and 3 g of 2-chloropropane into a 50 mL one-necked flask and stir to make a solution, and set aside. Under the protection of nitrogen, in a 50mL dry three-necked flask, add 1.1g of magnesium chips, a small amount of 2-chloropropane, and a small amount of tetrahydrofuran solvent, raise the temperature to 30-40°C, and initiate the reaction with bromoethane. Then the tetrahydrofuran solution of 2-chloropropane was added dropwise, and after the dropwise addition was completed, an insulation reaction was carried out, and the concentration of the obtained isopropylmagnesium chloride Grignard reagent was 1.7 mol / L.

[0024] (2) Grignard exchange: under the protection of nitrogen, add 10 g of 2,6-dichloro-4-fluoroiodobenzene and 20 ml of tetrahydrofuran into a 100 ml dry three-necked flask. Cool down to -20°C, slowly add the above-prepared isopropylmagnesium chloride Grignard rea...

Embodiment 3

[0028] (1) Preparation of isopropylmagnesium chloride Grignard reagent: first add 20 mL of tetrahydrofuran and 3 g of 2-chloropropane into a 50 mL one-necked flask and stir to make a solution, and set aside. Under the protection of nitrogen, in a 50mL dry three-necked flask, add 1.1g of magnesium chips, a small amount of 2-chloropropane, and a small amount of tetrahydrofuran solvent, raise the temperature to 30-40°C, and initiate the reaction with bromoethane. Then the tetrahydrofuran solution of 2-chloropropane was added dropwise, and after the dropwise addition was completed, an insulation reaction was carried out, and the concentration of the obtained isopropylmagnesium chloride Grignard reagent was 1.7 mol / L.

[0029] (2) Grignard exchange: under nitrogen protection, 7.4 g of 2,6-dichloro-4-fluoroiodobenzene and 20 ml of tetrahydrofuran were added to a 100 ml dry three-necked flask. Cool down to 10°C, slowly add the above-prepared isopropylmagnesium chloride Grignard reage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com