Mineral water bottle recovery crushing and cleaning device

A cleaning device and mineral water bottle technology, which is applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of raw materials that cannot be cleaned, long degradation cycle, air pollution, etc., to save manpower and material resources, save working time, The effect of speeding up the pace of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

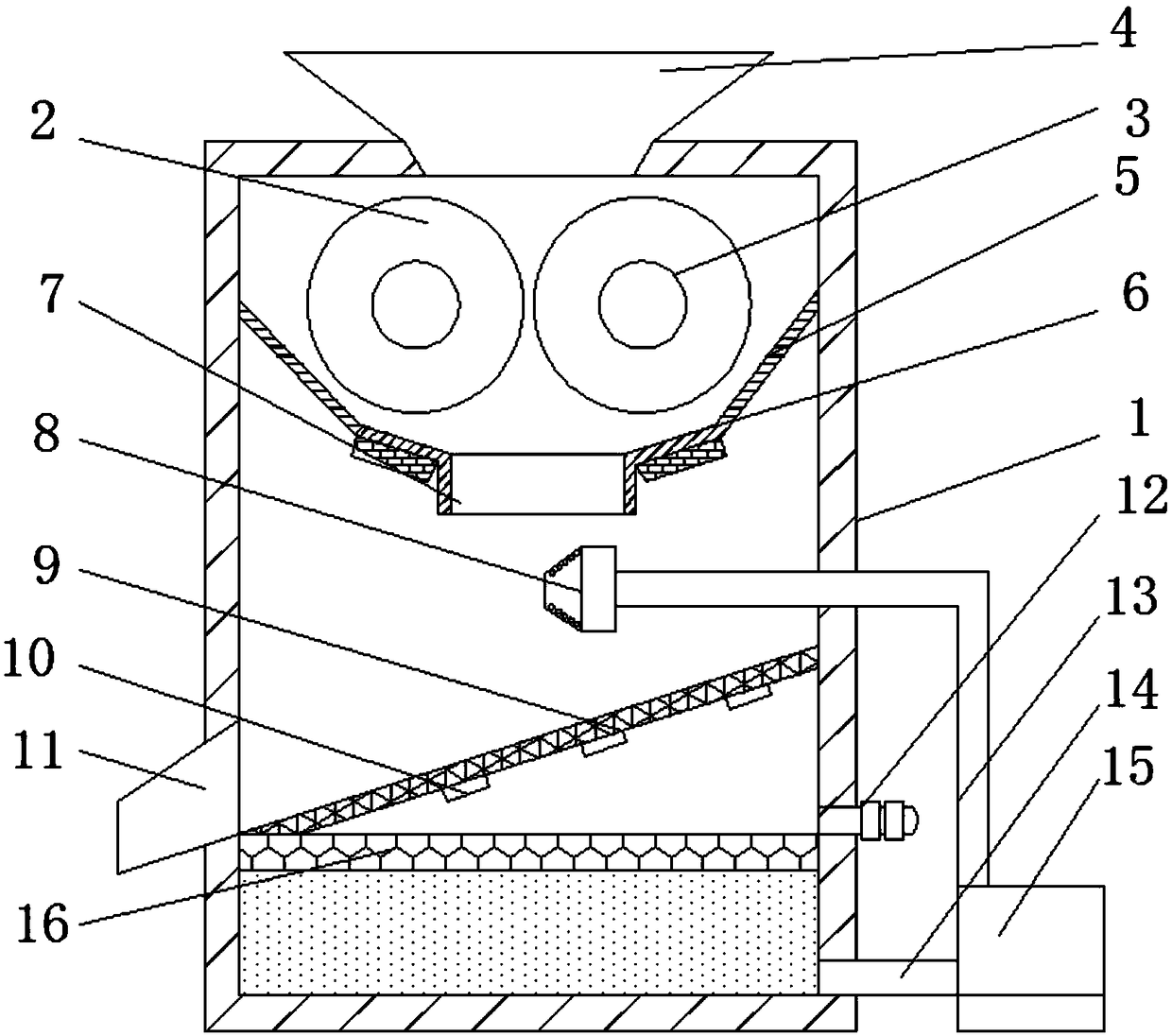

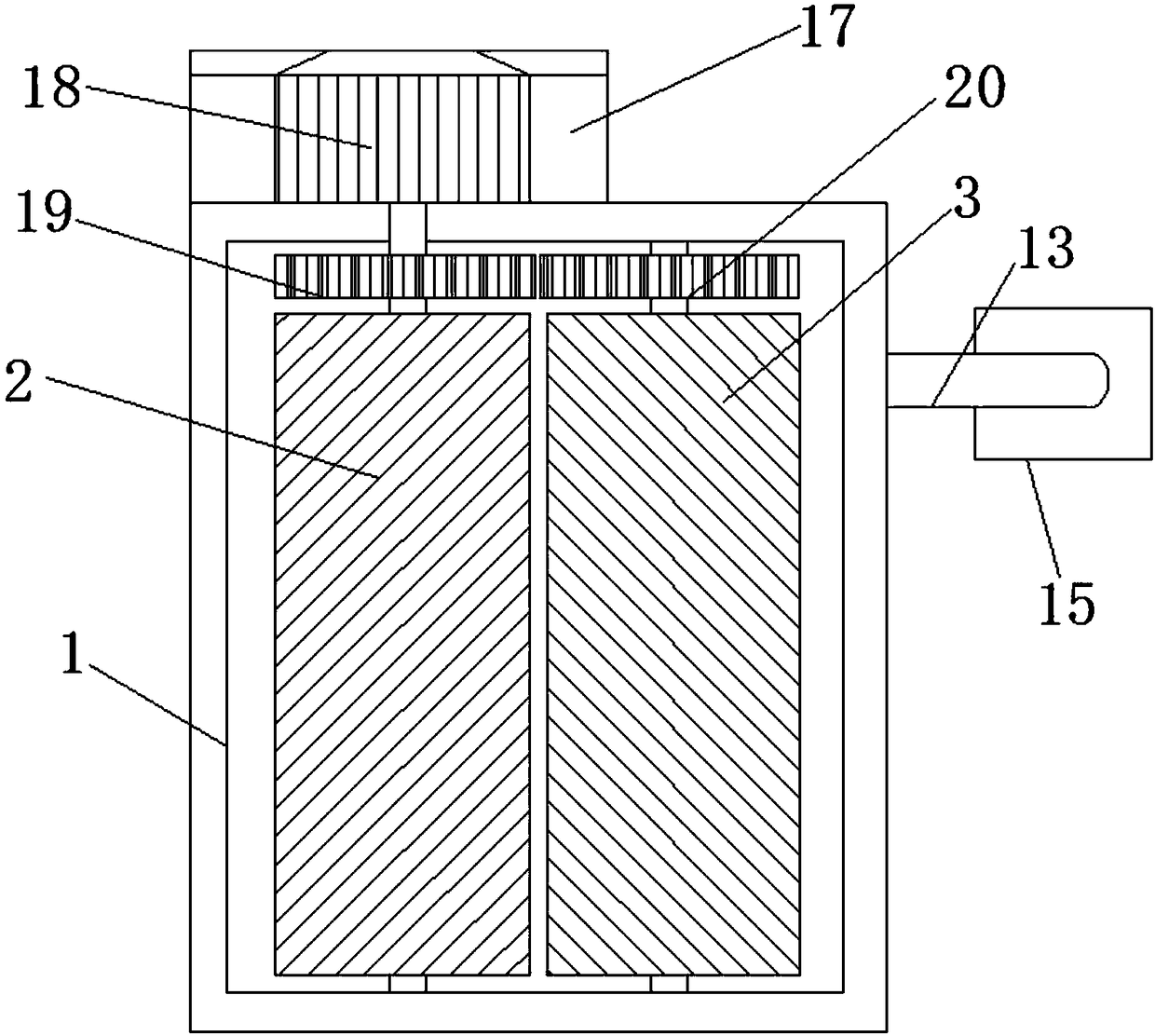

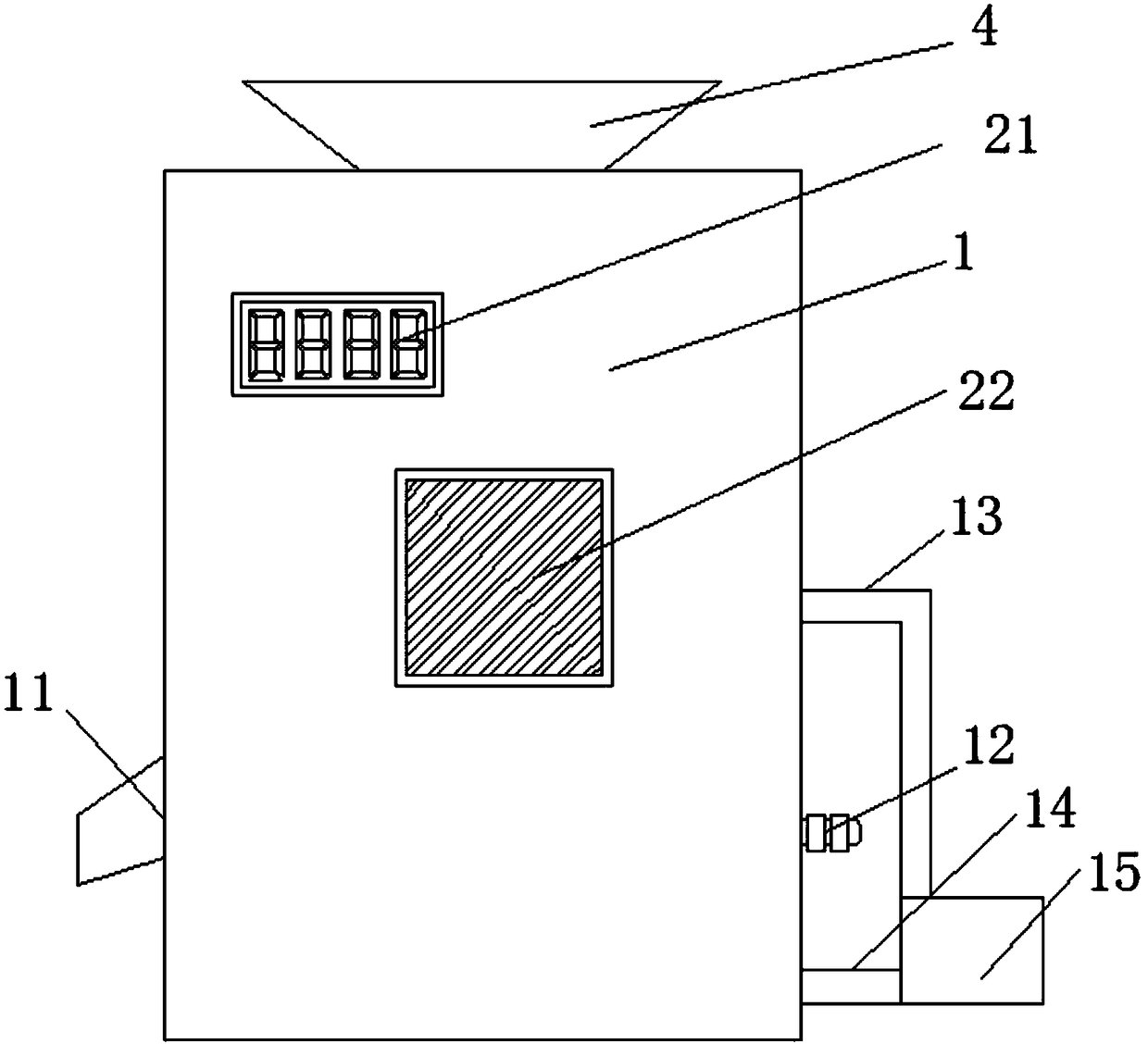

[0024] Reference Figure 1-3 , A mineral water bottle recovery, crushing and cleaning device, comprising a box body 1, a first through hole is opened at the center of the outer wall of the top of the box body 1, and the inner wall of the first through hole is welded with a first hopper 4, and the outer wall of the box body 1 passes The motor box 17 is fixed with bolts, and the inner wall of the motor box 17 is fixed with a motor 18 by bolts. The inner walls on the opposite sides of the box 1 are welded with two fixed shaft sleeves near the top, and the two fixed shaft sleeves are respectively inserted into the two fixed shaft sleeves. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com