A Welding Pool Stability Control Method and Its Application Based on Double Arc Vibration

A technology of welding molten pool and double arc, which is applied in the field of stability regulation of welding molten pool based on double arc vibration and arc heat source welding pool stability, can solve the problems of difficulty in automation and low manufacturing efficiency, and achieve improvement The effect of welding manufacturing efficiency, reducing high temperature liquid metal, and improving welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

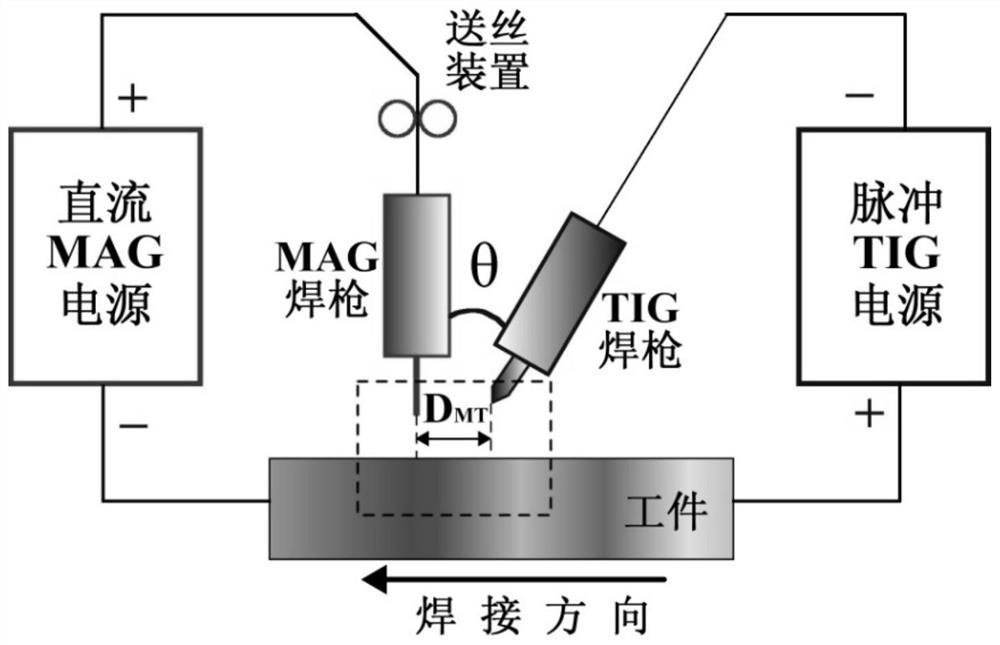

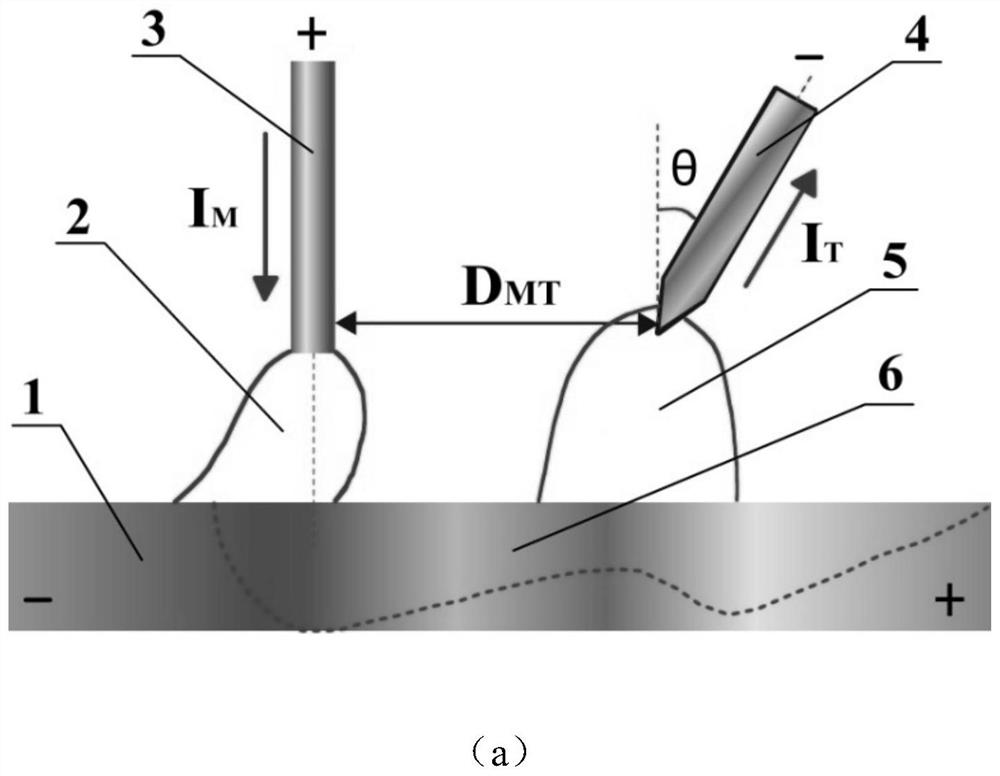

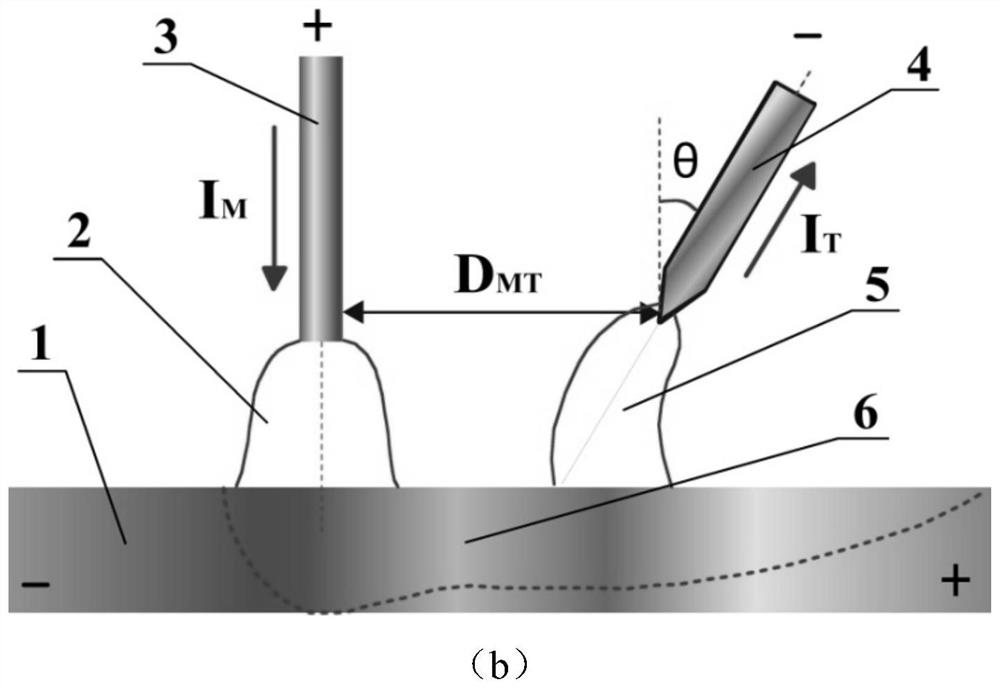

[0038] Taking the Q235-B plate butt transverse welding seam with a plate thickness of 24mm as an example, the welding process of MIG / MAG-TIG double arc vibration heat source applied to the high-efficiency welding method of butt transverse welding of medium and thick plates is described in detail. The welding process for butt weld horizontal welding of medium and thick plates is as follows:

[0039] A single-sided welding groove is processed on the test plate, the blunt edge of the root is 0-1.0mm, and the single-sided welding groove is V-shaped. After the test plate is assembled, the included angle is 10-30°. Positioning spot welding is adopted. After positioning, the test plate gap is 1.0-2.0mm. Before welding, grind the single-side welding groove and the range of 10-30mm on both sides, and clean the groove and the impurities on both sides. Combining the welding torches respectively connected to the gas shielded welding power source and the pulsed gas shielded welding power ...

Embodiment 2

[0043] Taking the arc additive manufacturing welding of ER5356 aluminum alloy welding wire with a diameter of 1.2mm as an example, the welding process of MIGTIG dual arc vibration heat source applied to arc additive manufacturing is described in detail. The implementation of arc additive manufacturing welding process is as follows:

[0044] The square aluminum alloy structural part required to be produced has a wall thickness of 10mm, a length, width, and height of 300mm, 300mm, and 600mm, respectively, and is formed by additive manufacturing with a multi-layer single-channel MIG-TIG double-arc vibration eutectic pool heat source.

[0045] Through the surfacing test, the process parameters of the deposited metal forming width of 9-10mm are obtained: MIG welding current 260A, TIG welding peak current 360A, TIG base value current 120A, pulse frequency of TIG current 80-120Hz, filament spacing 20mm, The welding speed is 12mm / s, and the flow rate of argon gas is 15-22L / min; under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com