Pesticide micro-capsule suspending agent and preparation method thereof

A technology of microcapsule suspensions and pesticides, applied in botany equipment and methods, biocides, animal repellents, etc., can solve problems affecting microcapsule size, wall thickness, capsule wall stability, and complex reaction conditions , to achieve the effect of ensuring the service life, changing the degree of intensity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

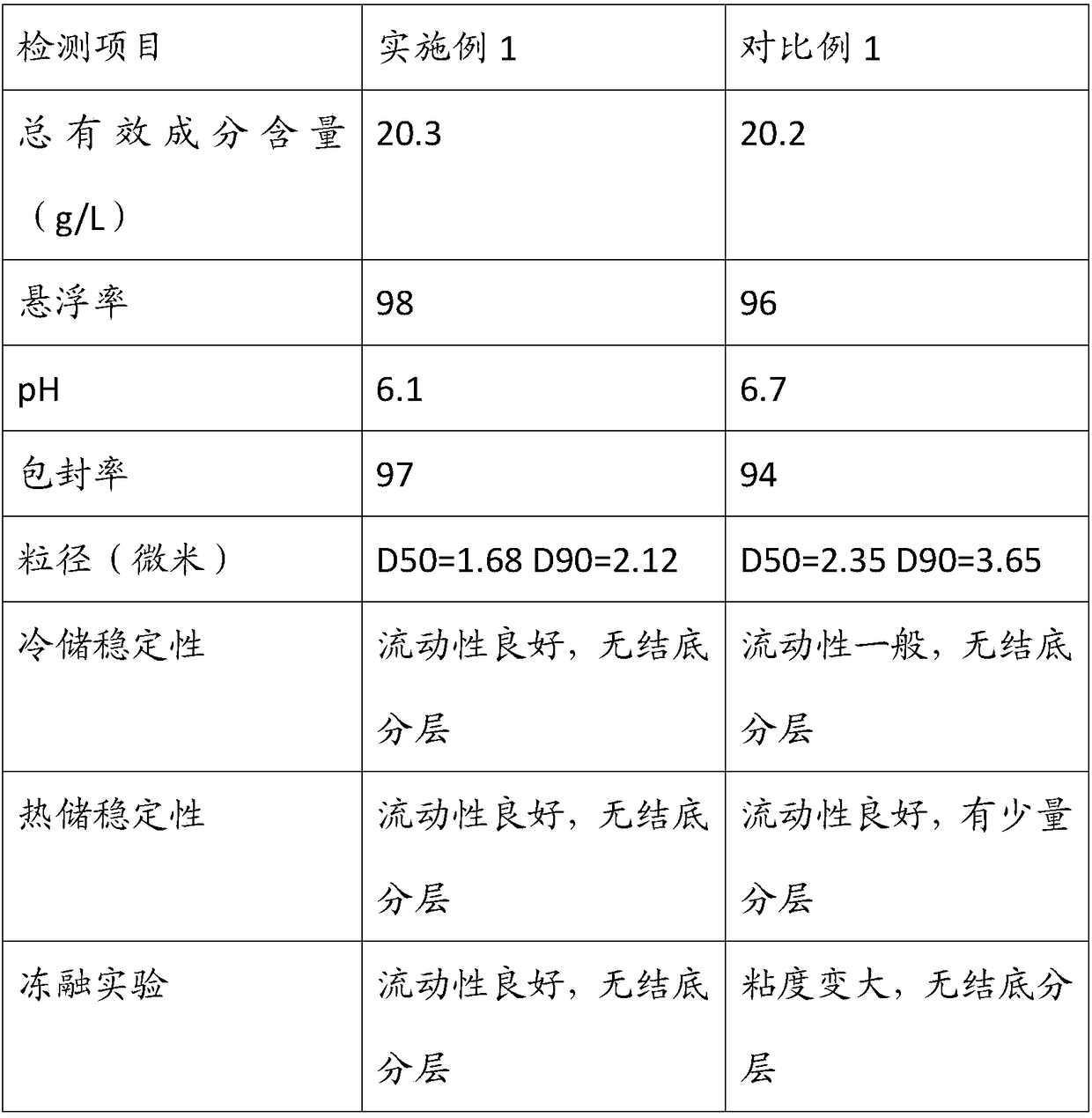

Examples

Embodiment 1

[0034] Prepare 20% bifenthrin microcapsules as follows

[0035] 1) Preparation of dispersed phase: 20% bifenthrin, 4% diphenylmethane diisocyanate and 5% calcium dodecylbenzenesulfonate were mixed evenly;

[0036] 2) Preparation of the continuous phase: 4% lignosulfonate, 1% ethylenediamine, 5% organic silicon defoamer and 40% water are stirred evenly;

[0037] 3) Forming of microcapsules: Put the above-mentioned dispersed phase and continuous phase into a stirred tank respectively, the dispersed phase and the continuous phase are equipped with the same injection pump, the dispersed phase stirred tank is injected at a speed of 100mL / min, and the continuous phase stirred tank is injected at a speed of 100 mL / min. Injected at a speed of 200ul / min, the dispersed phase and continuous phase solution form microcapsules in the channel of the microreactor, and the particle size of the microcapsules is between 1-2 microns;

[0038] 4) Curing of microcapsules: the temperature of the mi...

Embodiment 2

[0045] Prepare 30% pirimiphos-methyl microcapsules according to the following steps

[0046] 1) Preparation of dispersed phase: Mix 30% pirimiphos-methyl, 4% diphenylmethane diisocyanate and 3% styrylphenol polyoxyethylene ether;

[0047] 2) Preparation of the continuous phase: 4% of alkylphenol polyoxyethylene ether, 1% of ethylenediamine, 0.5% of silicone defoamer and 20% of water are stirred evenly;

[0048] 3) Forming of microcapsules: Put the above-mentioned dispersed phase and continuous phase into a stirred tank respectively, the dispersed phase and the continuous phase are equipped with the same injection pump, and both stirred tanks are injected at a speed of 100ul / min, the dispersed phase and the continuous phase are injected at a speed of 100ul / min. The phase solution forms microcapsules in the channel of the microreactor, and the particle size of the microcapsules can be between 5-6 microns;

[0049] 4) Curing of microcapsules: the temperature of the microreactor ...

Embodiment 3

[0056] Prepare 50% acetochlor microcapsules according to the following steps

[0057] 1) Preparation of dispersed phase: Mix 50% acetochlor, 4% diphenylmethane diisocyanate and 3% fatty alcohol polyoxyethylene ether;

[0058] 2) Preparation of the continuous phase: 4% modified naphthalenesulfonate, 1% ethylenediamine, 1% polyether defoamer and 20% water are stirred evenly;

[0059] 3) Forming of microcapsules: the above-mentioned dispersed phase and continuous phase are respectively loaded into a stirred tank, the dispersed phase and the continuous phase are equipped with the same injection pump, the dispersed phase stirred tank is injected at a speed of 200ul / min, and the continuous phase stirred tank is injected at a speed of 200ul / min. Injected at a speed of 130ul / min, the dispersed phase and continuous phase solution form microcapsules in the channel of the microreactor, and the particle size of the microcapsules can be between 3-4 microns;

[0060] 4) Curing of the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com