Electric machine

A motor shaft and housing technology, applied in the field of motor vehicles, can solve the problems of hindering the cooling of castings, weakening the heat dissipation of the rotating magnetic field winding, limiting the continuous load of the motor, etc., and achieves the effects of improving cooling, reducing eddy current loss and improving continuous load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

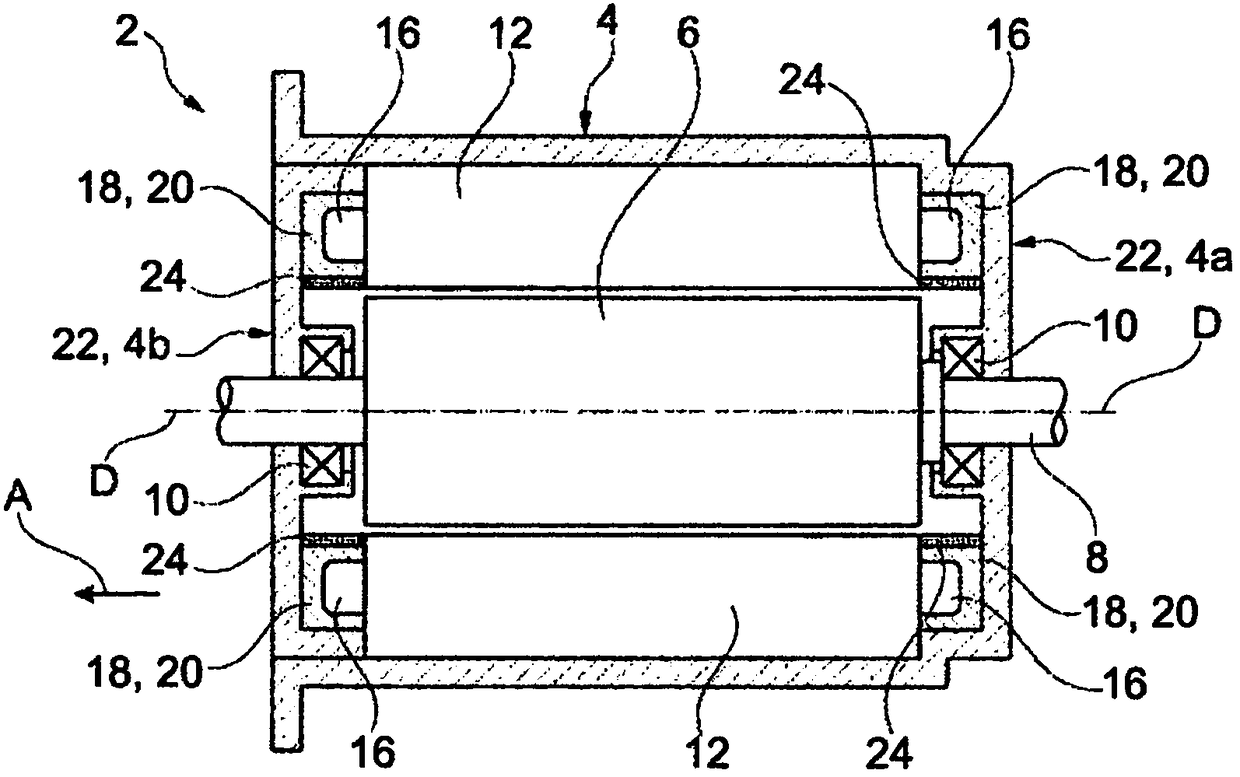

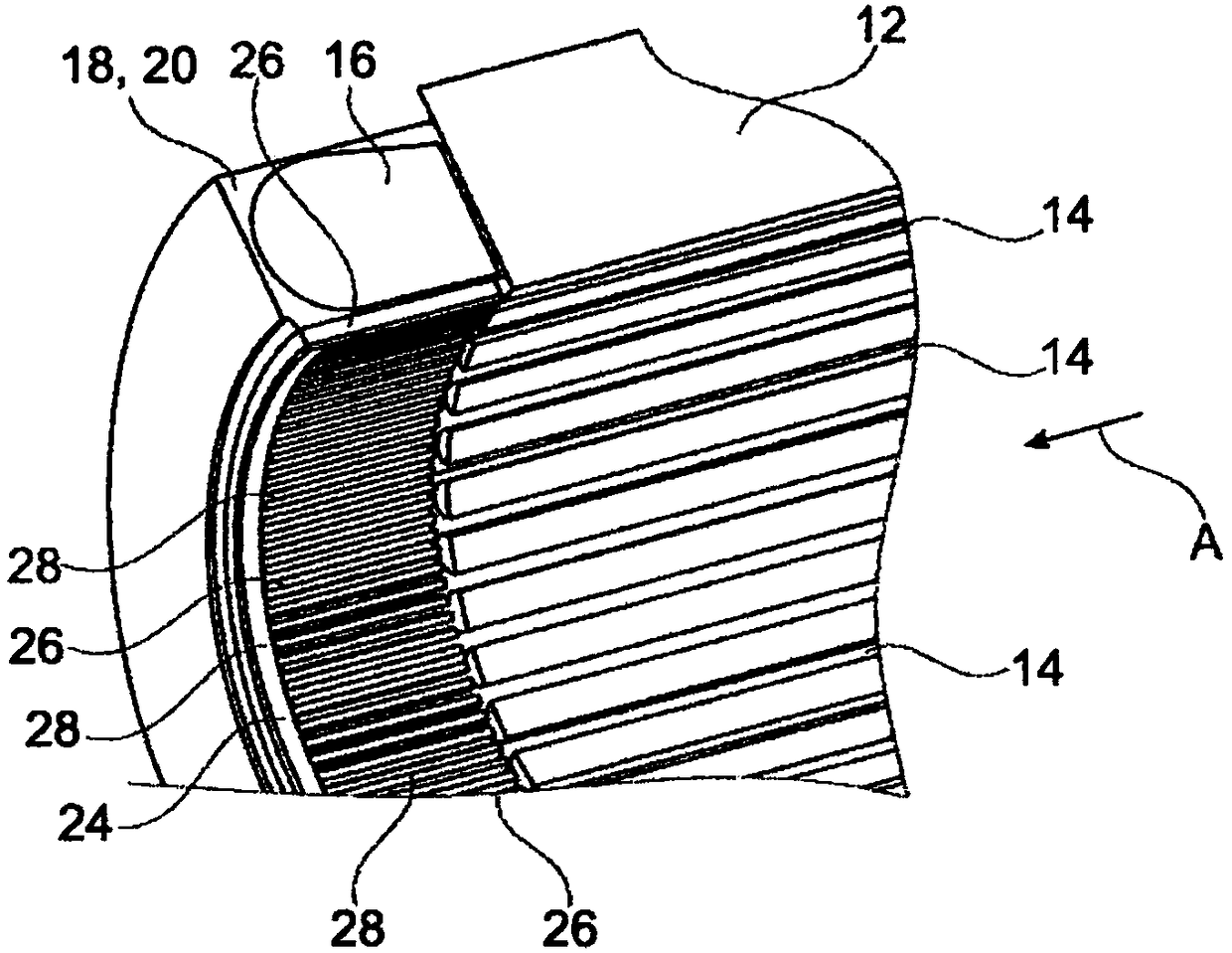

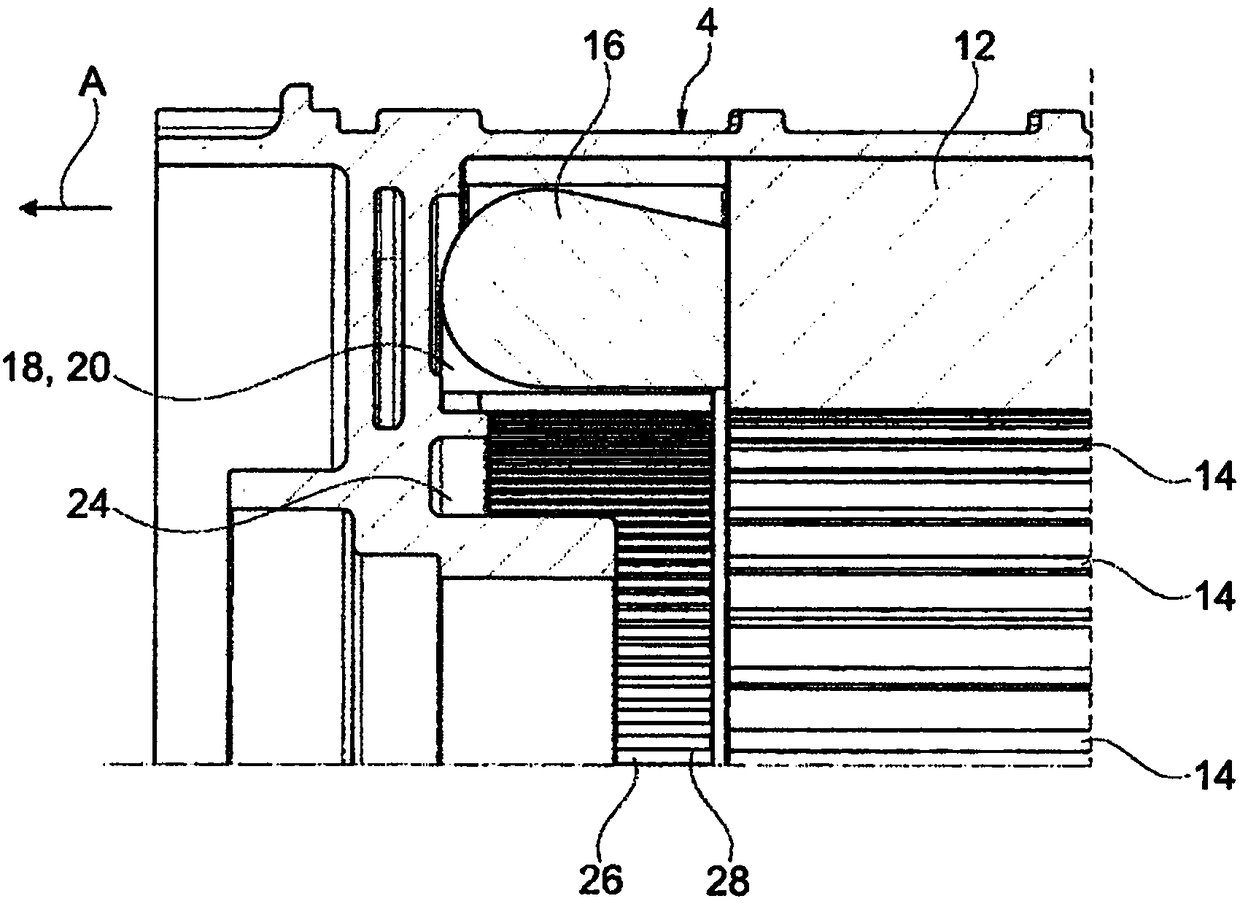

[0032] Corresponding components and parameters are always provided with the same reference symbols in all figures.

[0033] figure 1 The electric machine 2 shown is an electric drive of an electric vehicle or a hybrid vehicle. For this purpose, electric machine 2 is expediently designed as an asynchronous electric machine and integrated into the drive train of the electric or hybrid vehicle. The electric machine 2 comprises a (motor) housing 4 in which a rotor 6 is mounted rotatably about an axis D of rotation.

[0034] The rotor 6 is arranged axially fixed on a rotor shaft or motor shaft 8 , which is supported via two bearings 10 on opposite end sides of the housing 4 relative to the housing. The rotor 6 is enclosed within the housing by the stator 12 . The stator 12 comprises a stator pack or stator lamination pack (not specified in detail) which has a plurality of axially extending stator slots 14 on the inner circumferential side. In this case, the stator slots 14 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com